Nano-grade porous tin dioxide film gas sensitive material, and preparation method and application thereof

A technology of tin dioxide and gas-sensitive materials, which is applied in the fields of nanostructure manufacturing, nanotechnology, analytical materials, etc., can solve the problems of low detection limit, low sensitivity, complicated preparation process, etc., and achieves low detection limit and ultra-high gas-sensing response. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

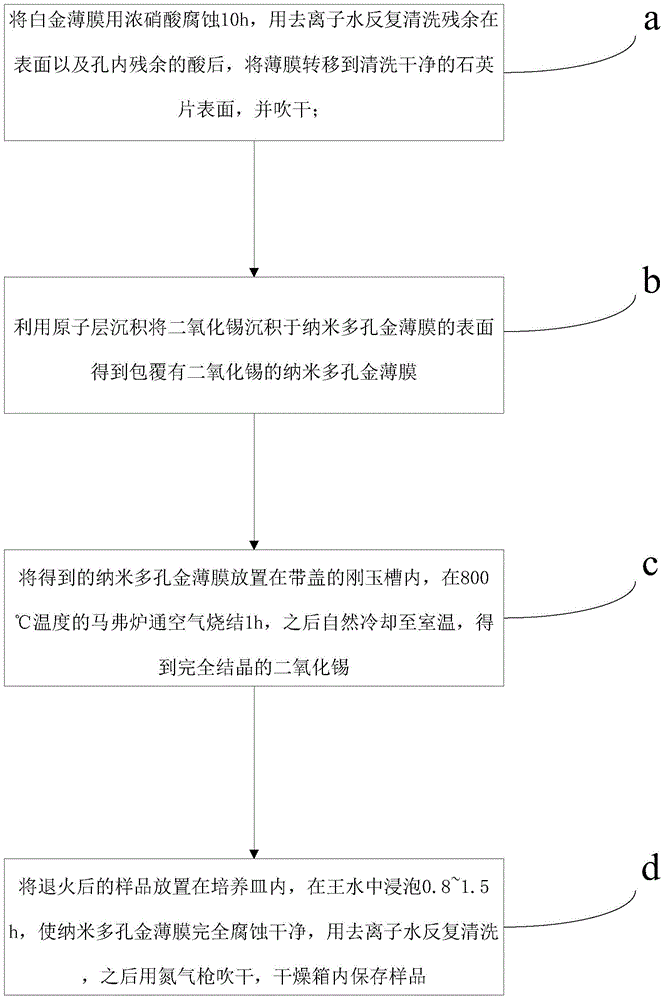

[0029] The concrete steps of the preparation method of a kind of nanoporous tin dioxide thin film gas sensitive material of the present invention are:

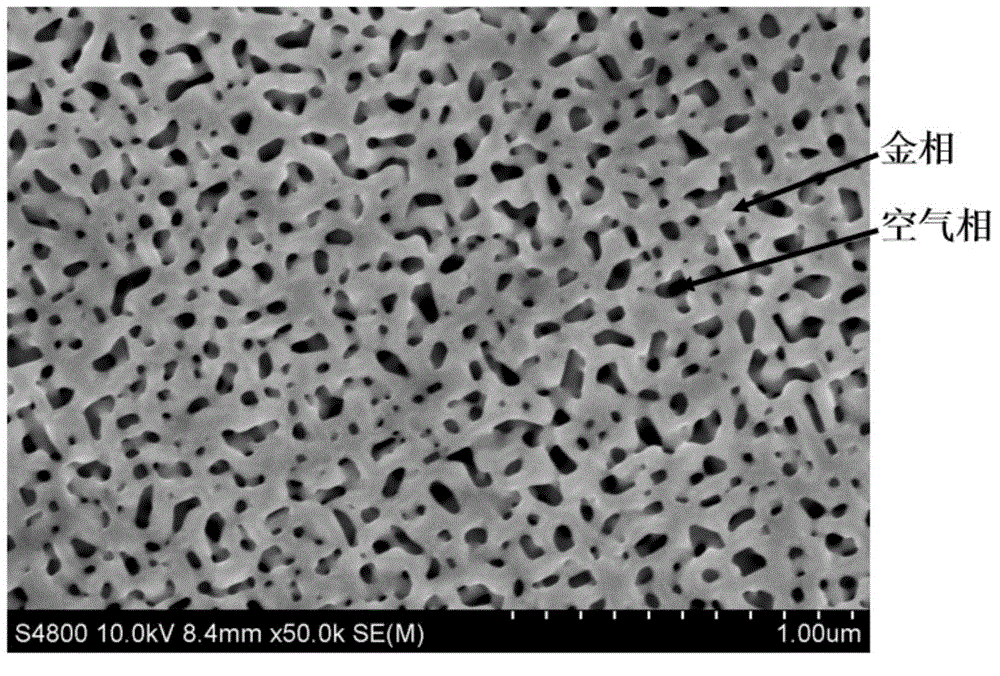

[0030] a) Cut a 13.25-carat platinum film into a square of 10mm×10mm, corrode it with concentrated nitric acid for 10h to obtain a nanoporous gold film, wash the remaining acid on the surface and in the pores repeatedly with deionized water, and then transfer the film to a cleaning Clean the surface of the quartz sheet, and dry it; b) Utilize atomic layer deposition to deposit tin dioxide on the surface of the nanoporous gold film to obtain a nanoporous gold film coated with tin dioxide; c) process the nanoporous gold film obtained in step b) The porous gold film is placed in a corundum tank with a cover, sintered in a muffle furnace at a temperature of 800 ° C for 1 h, and then naturally cooled to room temperature to obtain fully crystallized tin dioxide; d) hydrochloric acid and nitric acid are mixed in a volume ratio of 3: ...

Embodiment 1

[0036] a) Cut the quartz sheet into a rectangle of 10mm×15mm, ultrasonically clean it with deionized water, acetone, and ethanol for 15 minutes, and dry it with a nitrogen gun;

[0037]b) Cut the 13.25-carat platinum film into a square of 10 mm × 10 mm, corrode it with concentrated nitric acid for 10 h to obtain a nanoporous gold film, wash the remaining acid on the surface and in the pores repeatedly with deionized water, and then transfer the film to a cleaning Clean the surface of the quartz sheet and blow dry;

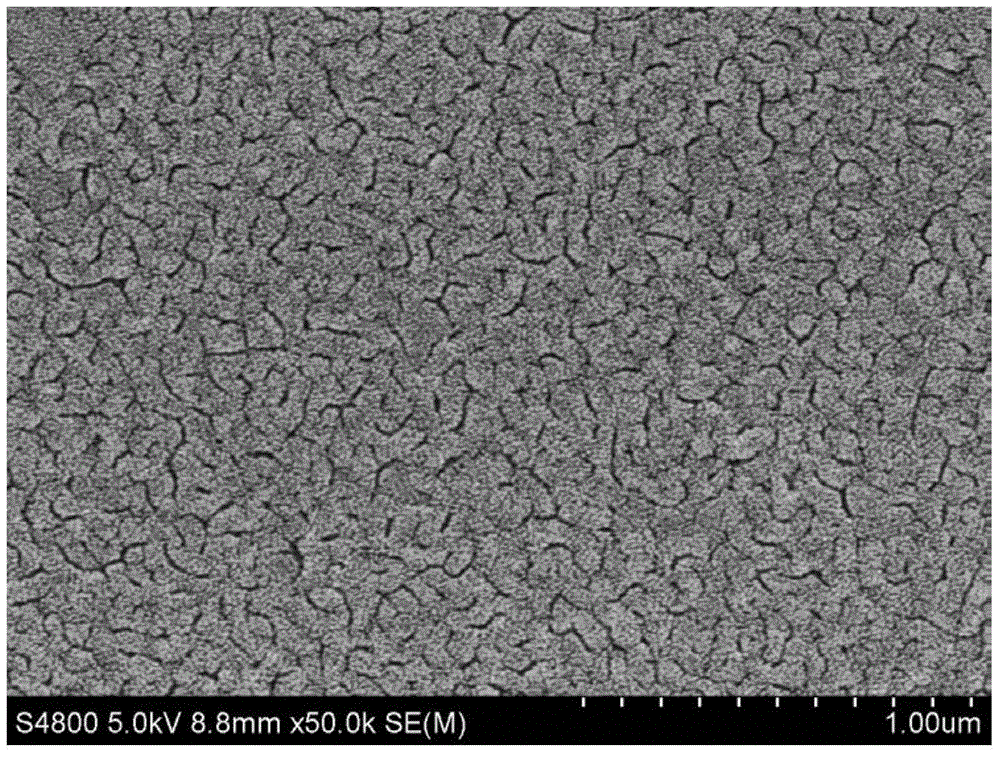

[0038] c) Setting the ALD reaction steps, the specific steps are: 1. Tetrakis(dimethylamino)tin (99.99% pure) pulse time: 1s; 2. Nitrogen gas treatment time: 20s; 3. Ozone pulse time: 0.03s; 4. Nitrogen treatment time: 20s. Cycle 300 times. Obtain a nanoporous gold film coated with tin dioxide after the reaction finishes;

[0039] d) Place it in a corundum tank with a cover, sinter it in a muffle furnace at a temperature of 800° C. for 1 hour, and then cool it n...

Embodiment 2

[0042] Dip a little silver paste with one end of a toothpick, and place it in the middle of the opposite sides of the tin dioxide film. Let it stand overnight at room temperature, and test it after the electrode becomes dry and hard.

[0043] The gas sensitivity test uses a German HITEC ZANG bioreactor / fermenter equipped with Agilent 34970A - Gmix TM Gas mixing device, the heating device is a heating plate with an intelligent temperature controller (the heating plate is made of corundum plate). Put the sample in a sealed tank, connect the wires, pass in dry nitrogen, heat to 300°C and start the test after the resistance reading is stable. The test concentration gradient is as follows: 10ppm, 5ppm, 1ppm, 500ppb, 200ppb, 170ppb, get Resistance-time change curve (such as Figure 5 ). The test result finds that the nanoporous tin dioxide thin film obtained by the present invention under the test condition of 300° C. shows extremely fast response recovery characteristics and extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com