Sandwiched porphyrin-phthalocyanine mixed double-layer metal complex nanotube and preparation method and application thereof

A porphyrin phthalocyanine and double-layer metal technology, which is applied in the field of sandwich hybrid porphyrin phthalocyanine double-layer metal complex nanotubes and its preparation, can solve the problems of poor stability and high working temperature, and achieve good gas detection Practical value, low response concentration and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

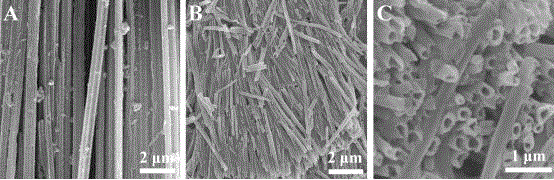

[0044] 1.1

[0045] ①Put the anodized aluminum film with a pore size of 200nm into a beaker, then place it in an ultrasonic cleaner, and use solvents of different polarities including water, ethanol, acetone, and chloroform to ultrasonically clean it for ten minutes in sequence, and then vacuum dry it for later use.

[0046] ②Dissolve 0.003mmol Eu(TpyP)(Pc) in 1 mL THF to obtain a solution of Eu(TpyP)(Pc) in THF; soak the dried and clean anodic aluminum oxide film (AAO) in Eu(TpyP)(Pc ) in tetrahydrofuran solution, after standing for 8 hours, the tetrahydrofuran solution was sucked out, and vacuum-dried; Eu(TpyP)(Pc) nanotubes containing AAO were obtained.

[0047] ③The Eu(TpyP)(Pc) nanotubes containing AAO were dissolved with 6 mol / L sodium hydroxide aqueous solution to remove the anodic aluminum oxide film, remove the liquid, and collect the solid product.

[0048] ④ Wash the obtained Eu(TpyP)(Pc) nanotubes with distilled water, and then diffuse them in an aqueous solution ...

Embodiment 2

[0070] Example 2 Preparation of Eu(TpyP)(Pc) nanotube nitrogen dioxide gas sensor

[0071] (1) The substrate of the ITO conductive glass interdigitated electrode was ultrasonically treated three times with toluene, acetone, ethanol, and deionized water, respectively, for five minutes each time, and vacuum-dried for later use.

[0072] (2) Use a dropper to drop-coat 1 mg of Eu(TpyP)(Pc) nanotubes prepared in Example 1 onto the interdigitated electrodes of the above-mentioned treated ITO conductive glass substrate, and let it dry naturally to obtain a gas sensor. The gas sensor of the sensor.

Embodiment 3

[0073] Embodiment 3 Performance measurement of nitrogen dioxide gas sensor

[0074] The gas sensor prepared in Example 2 was used to prepare a Eu(TpyP)(Pc) nanotube gas sensor, a gas sensor test device was constructed, and a gas sensor test was carried out. The gas-sensing test process is carried out in a relatively mild environment (room temperature, external atmospheric pressure and dry air) and a fixed bias voltage of 5V between the two electrodes for gas-sensing performance. Test equipment used: Agilent B290a precision source / measure unit. Wherein, the gas sensor prepared by each Eu(TpyP)(Pc) nanotube prepared in embodiment 1 is tested respectively, and the test results are consistent; Figure 9-13 shown. Such as Figure 9 Shown, Eu(TpyP)(Pc) nanotube gas sensor of the present invention is right 5-100ppmNO 2 The response time is 300 s and the recovery time is 1375 s. Figure 10 It shows that the sensitivity of the Eu(TpyP)(Pc) nanotube gas sensor has a linear relation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com