Aluminum alloy refining agent and preparing technology thereof

A preparation process and refining agent technology, which is applied in the field of metal smelting and processing, can solve problems such as uneven diffusion, unevenness, and process stability effects, and achieve the effects of optimizing the production process, improving mechanical properties, and increasing production efficiency

Active Publication Date: 2017-02-08

ZHEJIANG JINFEI KAIDA WHEEL

View PDF7 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, on the one hand, the massive aluminum-titanium-boron alloy block naturally melts slowly and diffuses unevenly, which affects its grain refinement effect; on the other hand, aluminum-titanium-boron is usually put into the aluminum alloy melt transfer bag, in order to prevent aluminum When the alloy melt temperature drops and solidifies, it will generally be transferred to the holding furnace in time, and the aluminum, titanium and boron will sink to the bottom of the transfer bag, resulting in insufficient melting or uneven diffusion of the aluminum, titanium and boron alloy block, which will have a certain impact on process stability.

Method used

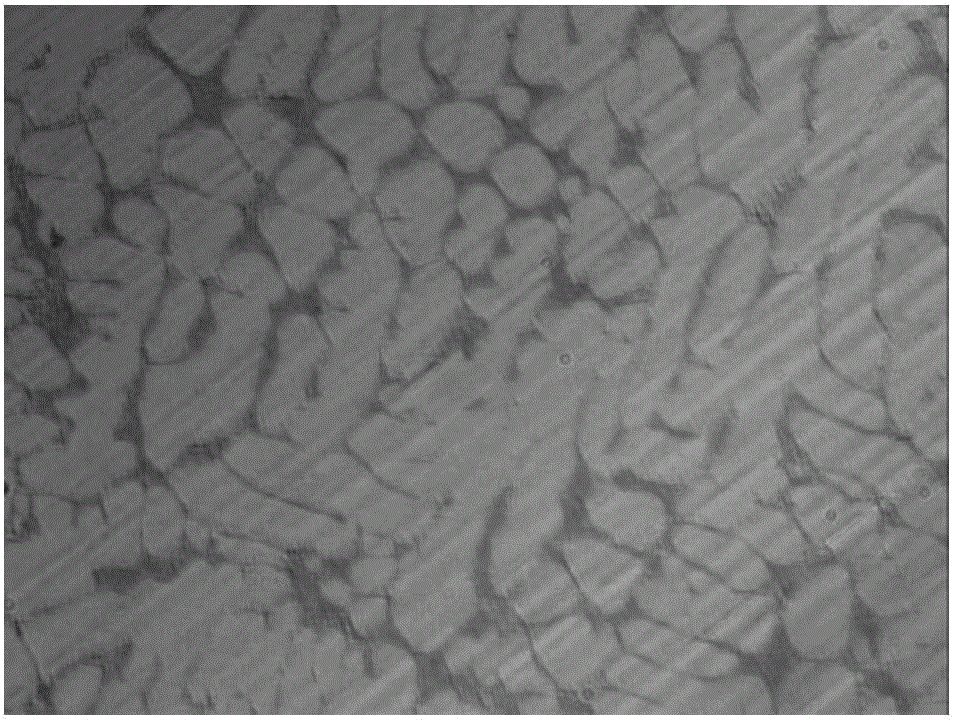

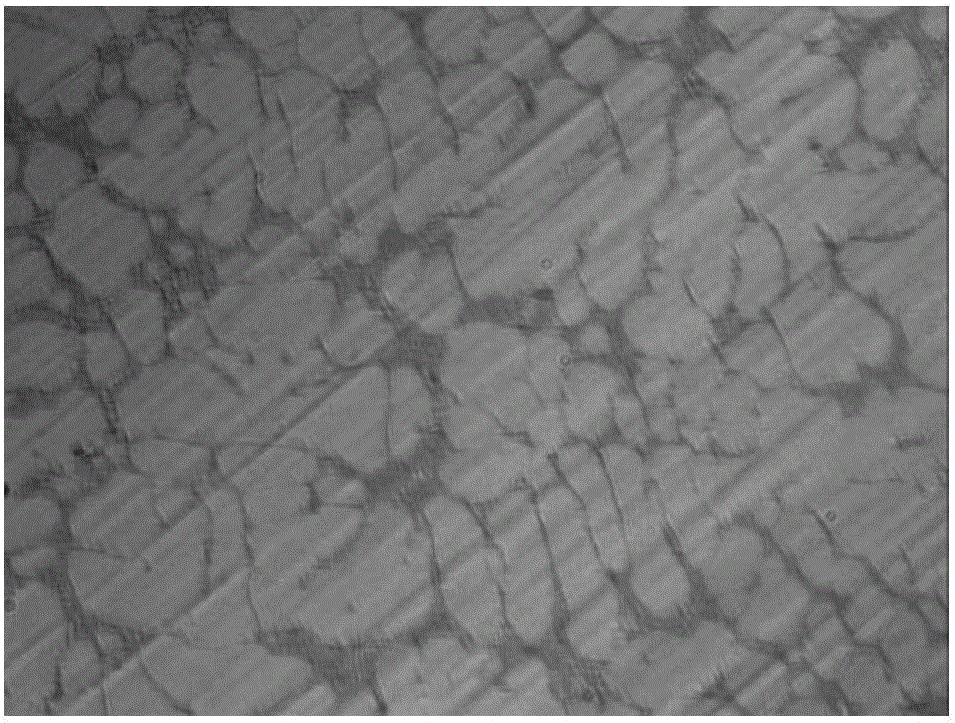

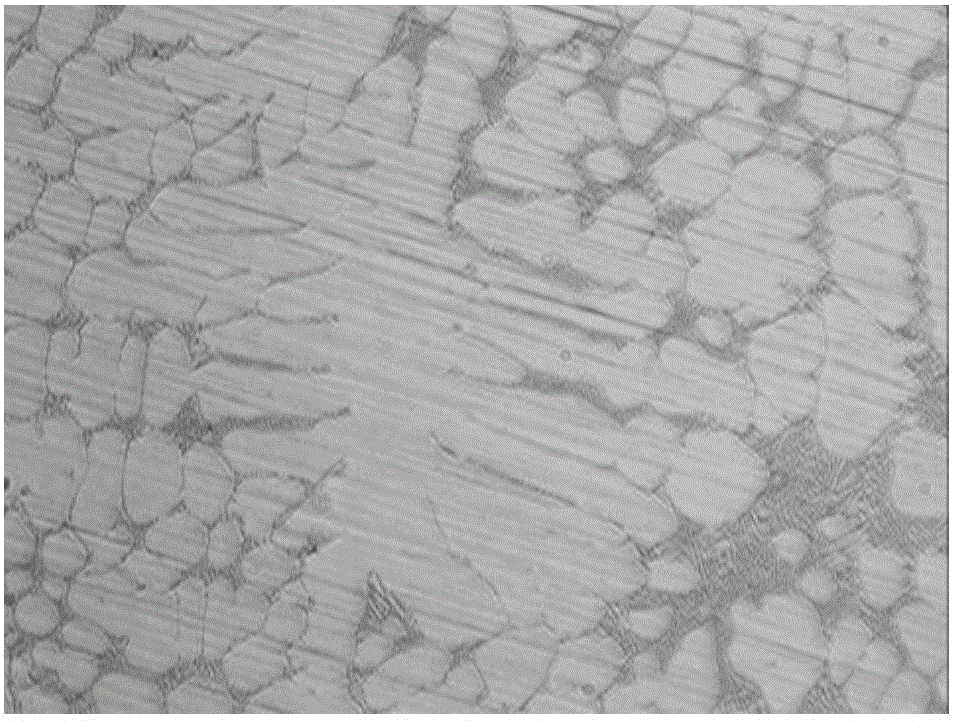

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0107] Formula of aluminum alloy refining agent for refining aluminum alloy melt of automobile aluminum wheel hub

[0108]

Embodiment 2

[0110] Formula of aluminum alloy refining agent for motorcycle aluminum wheel hub aluminum alloy melt refining

[0111]

Embodiment 3

[0113] Formula of aluminum alloy refining agent for refining aluminum alloy melt of light alloy material

[0114]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides an aluminum alloy refining agent and a preparing technology thereof. The aluminum alloy refining agent comprises, by mass part, 25 parts to 35 parts of sodium chloride, 20 parts to 30 parts of potassium chloride, 5 parts to 10 parts of sodium fluosilicate, 10 parts to 20 parts of sodium fluoride, 5 parts to 10 parts of potassium fluotitanate, 5 parts to 10 parts of potassium fluoborate, 5 parts to 10 parts of sodium carbonate, 10 parts to 20 parts of sodium sulfate, 1 part to 5 parts of potassium nitrate and 2 parts to 5 parts of potassium fluoroaluminate. According to the aluminum alloy refining agent, through the optimized formula, the aluminum alloy refining agent can achieve the aim of refining of deslagging and degassing, the effective grain refining effect is achieved, in the process of deslagging and degassing refining of aluminum alloy melt, the grains are refined, the grains are evenly distributed in the aluminum alloy melt, and therefore the working procedures of intermediate alloy adding and the like in modification of the aluminum alloy melt can be reduced, the production technology of the aluminum alloy is optimized, and the production efficiency of the aluminum alloy is improved.

Description

technical field [0001] The invention relates to the field of metal smelting and processing, in particular to an aluminum alloy refining agent and a preparation process of the aluminum alloy refining agent. Background technique [0002] The existing aluminum alloy refining agent uses inert gas such as nitrogen as the carrier, sprays it into the molten aluminum alloy through a powder sprayer, and reacts physically and chemically with impurities in the molten aluminum alloy through the stirring of the inert gas to adsorb oxides. Impurities such as hydrogen and hydrogen float up to the surface of the aluminum alloy melt, so as to achieve the refining purpose of removing slag and degassing. [0003] At present, in order to improve the mechanical properties and process performance of many aluminum alloy casting products, block-shaped aluminum-titanium-boron intermediate alloys are put into the aluminum alloy melt for modification treatment. The aluminum-titanium-boron alloy blocks...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C1/06C22C1/02C22C21/00

CPCC22C1/026C22C1/06C22C21/00

Inventor 李宏林星金根友卓文琪杨胜王奇

Owner ZHEJIANG JINFEI KAIDA WHEEL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com