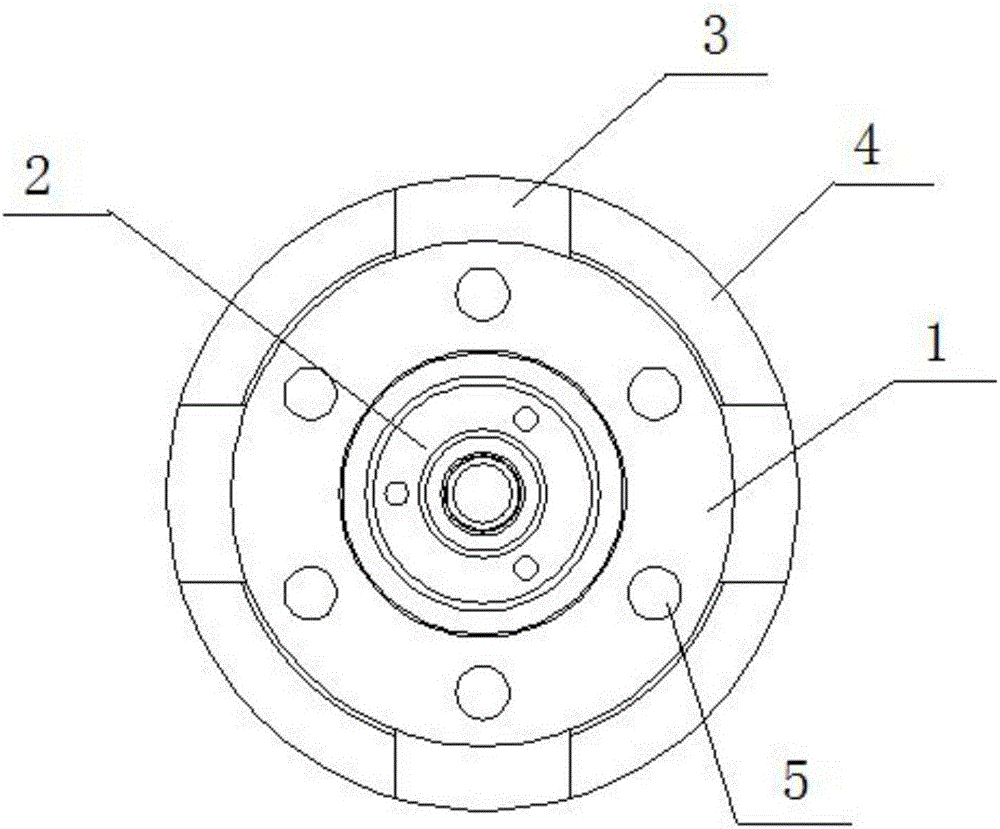

Bottom valve

A bottom valve and main body technology, applied in the field of powder metallurgy, can solve the problems of unsatisfactory quality and waste of raw materials, etc., and achieve the effects of increasing the induced internal stress, reducing the bending strength and improving the surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

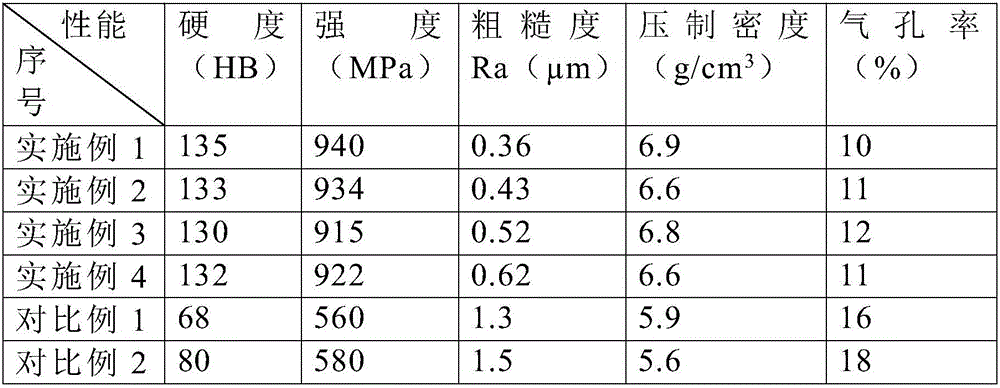

Examples

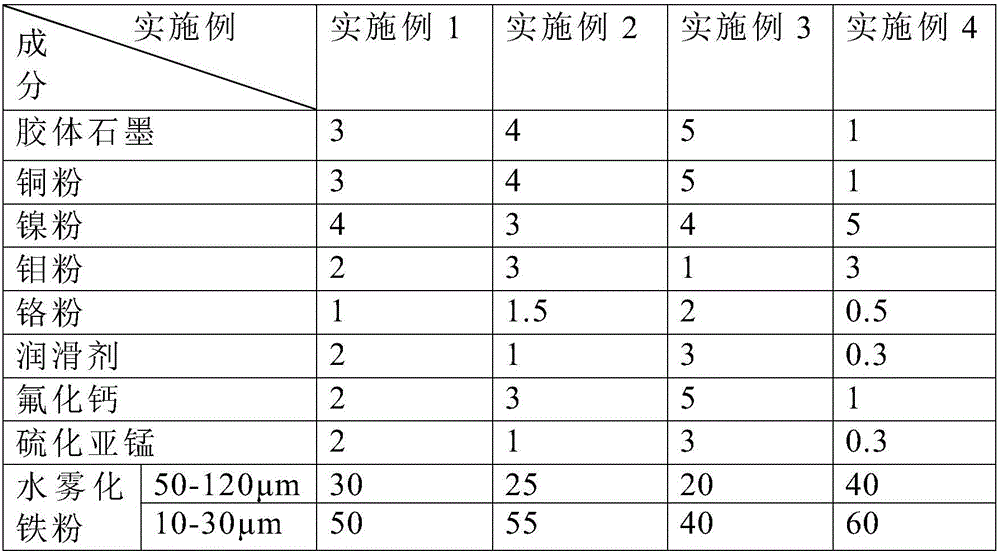

Embodiment 1

[0052] Mixing: Weigh the raw materials according to the composition and parts by weight of the bottom valve described in Table 1, Example 1, pour the weighed raw materials into a powder mixer and mix to obtain a uniform iron-based powder mixture; the lubricated The agent is a lubricant particle made by mixing polyvinyl isobutyl ether, metal oxide particles, zinc stearate, and fatty acid bisamide in proportion and wrapped by paraffin powder. The mass percentages of each component in the lubricant particle are respectively It is: polyvinyl isobutyl ether 45%, metal oxide particles 11%, zinc stearate 6%, fatty acid bisamide 38%; the metal oxide particles are calcium oxide 5% and aluminum oxide 6% (accounting for mass percent of the total mass of lubricant particles).

[0053] Compression molding: Feed the iron-based powder mixture into the molding machine, under the mixed gas of hydrogen and nitrogen (the volume percentage of hydrogen and nitrogen is 1-3.8%: 96.2-99%), the bottom...

Embodiment 2

[0057] Mixing: Weigh the raw materials according to the composition and parts by weight of the bottom valve described in Table 1, Example 2, pour the weighed raw materials into a powder mixer and mix to obtain a uniform iron-based powder mixture; the lubricated The agent is a lubricant particle made by mixing polyvinyl isobutyl ether, metal oxide particles, zinc stearate, and fatty acid bisamide in proportion and wrapped by paraffin powder. The mass percentages of each component in the lubricant particle are respectively It is: polyvinyl isobutyl ether 48%, metal oxide microparticles 11%, zinc stearate 7%, fatty acid bisamide 34%; described metal oxide microparticles are calcium oxide 5% and aluminum oxide 6% (accounting for mass percent of the total mass of lubricant particles).

[0058] Compression molding: Feed the iron-based powder mixture into the molding machine, under the mixed gas of hydrogen and nitrogen (the volume percentage of hydrogen and nitrogen is 1-3.8%: 96.2-...

Embodiment 3

[0062] Mixing: Weigh the raw materials according to the composition and parts by weight of the bottom valve described in Table 1, Example 3, pour the weighed raw materials into a powder mixer and mix to obtain a uniform iron-based powder mixture; the lubricated The agent is a lubricant particle made by mixing polyvinyl isobutyl ether, metal oxide particle calcium oxide, zinc stearate, and fatty acid bisamide in proportion and wrapping it with paraffin powder. The mass of each component in the lubricant particle is The percentages are respectively: 40% of polyvinyl isobutyl ether, 12% of metal oxide particles of calcium oxide, 8% of zinc stearate, and 40% of fatty acid bisamide.

[0063] Compression molding: Feed the iron-based powder mixture into the molding machine, under the mixed gas of hydrogen and nitrogen (the volume percentage of hydrogen and nitrogen is 1-3.8%: 96.2-99%), the bottom valve blank is obtained by one-time compression molding ; The pressing pressure is 280M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com