Preparation method of TiO2-Graphene composite material

A technology of composite materials and raw materials, which is applied in the manufacture of fuel cell parts, fuel cells, and final products. It can solve the problems of lack of preferred orientation and easy agglomeration of crystal growth, achieve high electrochemical stability and activity, and improve dispersion. degree, corrosion prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] see Image 6 , the present invention discloses a TiO 2 -The preparation method of Graphene composite material, described preparation method comprises:

[0035] Step 1. Using flake graphite as raw material, adopting improved Hummer's method to prepare GO solution;

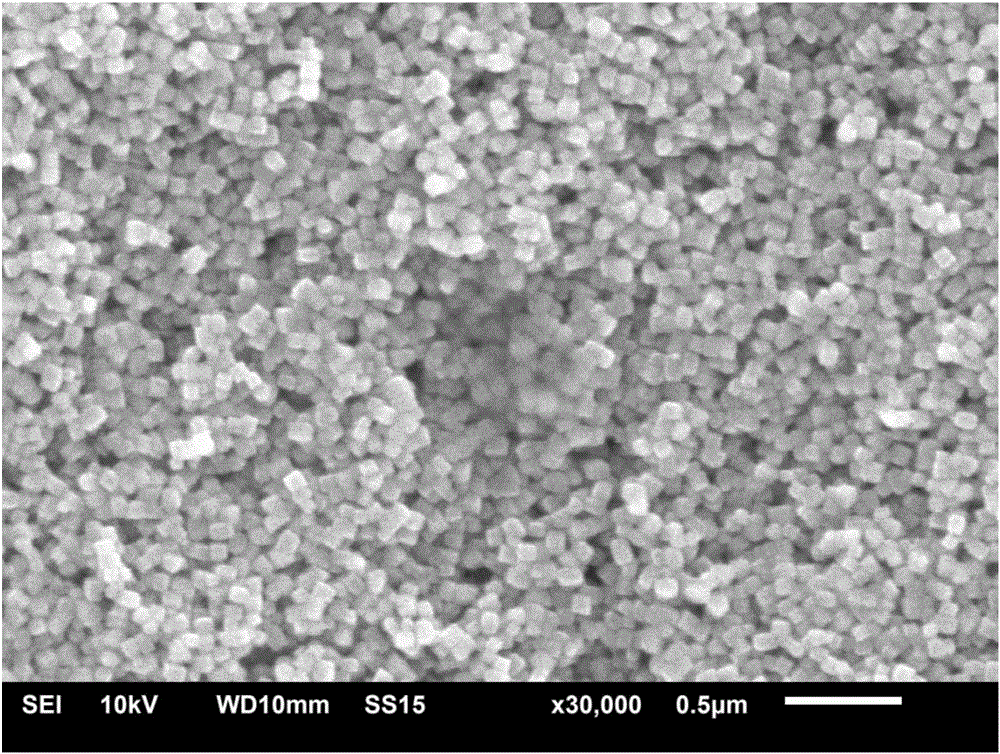

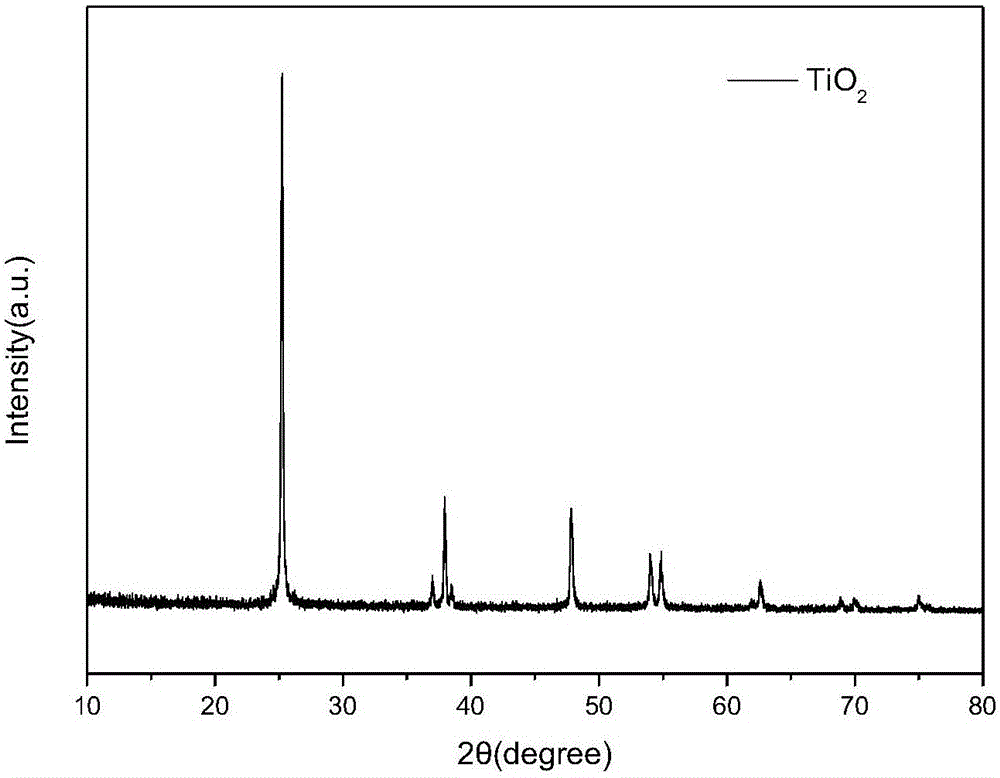

[0036] Step 2. Take 1-butyl-3 methylimidazolium tetrafluoroborate [bmin][BF 4 ], glacial acetic acid and water are fully mixed, then add tetrabutyl titanate drop by drop, stir magnetically until the solution is bright white, and then ultrasonically treat it until it is colorless and transparent, and use microwave-assisted ionothermal method to treat at 180°C for 25min. Obtained TiO 2 The samples were washed several times with deionized water and absolute ethanol, and dried for use;

[0037] TiO 2 The precursor of [bmin][BF was added under acidic conditions 4 ], using microwave-assisted ionothermal method, reacted at 180°C for 25min;

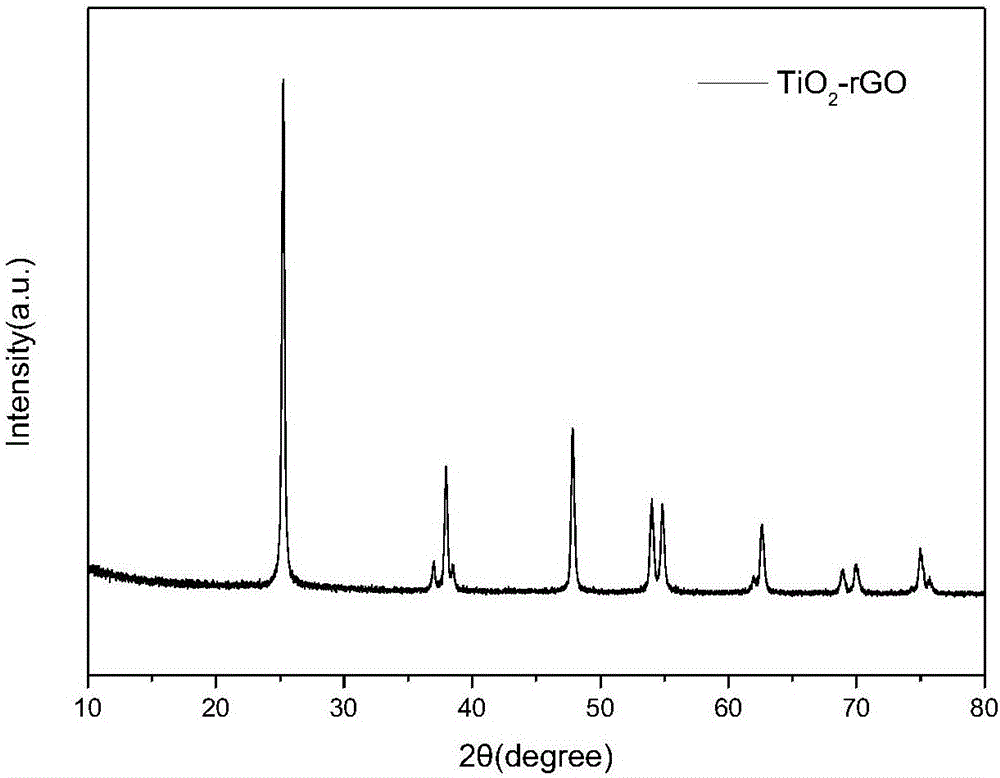

[0038] Step 3. Take different quality GO and TiO respectively 2 Tho...

Embodiment 2

[0041] This embodiment differs from Example 1 in that 20 mg of GO and 80 mg of TiO are used 2 mixed to obtain TiO 2 -Graphene composite material, in which Graphene content is 20%, and the rest is TiO 2 , the other steps are the same as in the first embodiment.

Embodiment 3

[0043] This embodiment differs from Example 1 in that 30 mg of GO and 70 mg of TiO are used 2 mixed to obtain TiO 2 -Graphene composite material, in which Graphene content is 30%, and the rest is TiO 2 ,, other steps are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com