A submicron anisotropic samarium iron nitrogen magnet powder and a method for preparing a hybrid bonded magnet therefrom

An anisotropic, bonded magnet technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of SmFeN magnetic powder without emphasizing particle size characteristics, SmFeN anti-oxidation and anti-corrosion capabilities Strong, no problems such as the optimal proportioning method of samarium iron nitrogen weight ratio have been found, to achieve the effect of improving mechanical properties and corrosion resistance, strong oxidation resistance, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

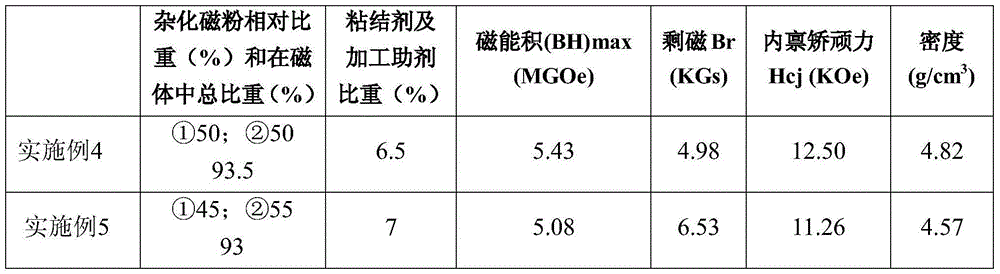

Examples

Embodiment 1

[0067] Example 1 Preparation of anisotropic samarium-iron-nitrogen magnetic powder with submicron single crystal particles

[0068] Mix other raw materials except nitrogen, which contain rare earth elements Sm, Nd, Ce, and iron Fe, Co, Nb, and the atom percentage of the mixture is Sm 8.5 Nd 1.5 Ce 1.0 Fe 76 Co 8 Nb 5 .

[0069] The samarium-iron alloy with good single-phase properties is prepared by custom-made equipment and rapid-setting thin slice technology. The speed of the quick-setting rotor is 1-4 meters per second, resulting in a thin sheet with a thickness of 0.1-0.5 mm and a width of 1-5 mm. No annealing treatment is required.

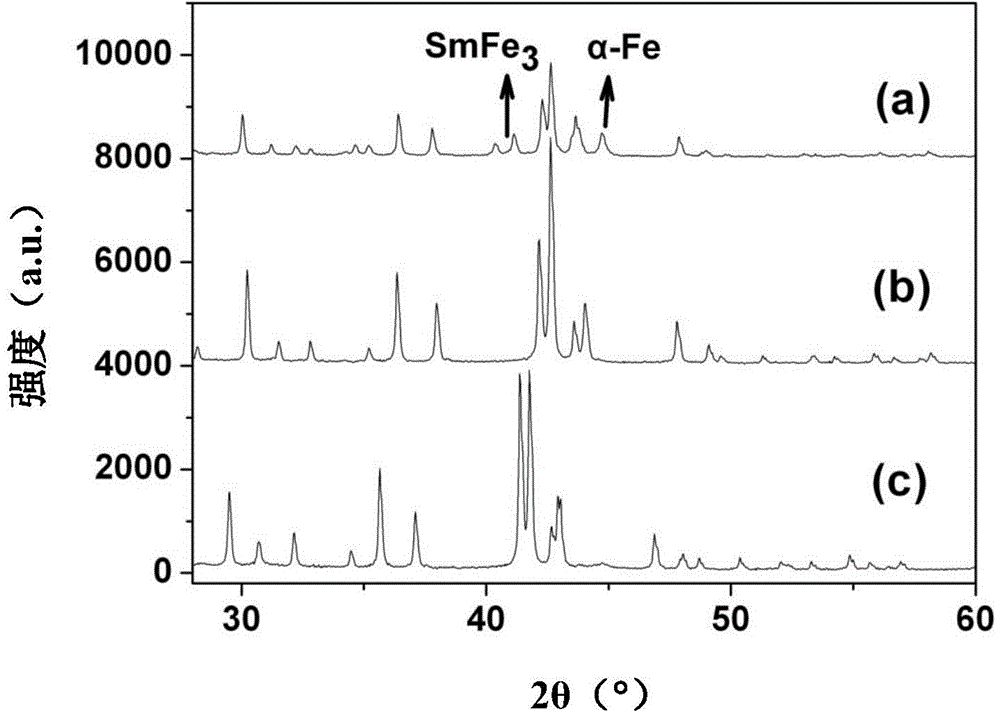

[0070] The quick-setting flakes are placed in nitrogen for gas-solid phase reaction, the nitriding temperature is 500°C, and the reaction time is 6 hours. The X-ray diffraction comparison chart of the samarium iron quick-solidified flakes before and after nitriding is as follows figure 1 Shown. figure 1 It shows that after nitrogen absorption, s...

Embodiment 2

[0075] Example 2 Preparation of anisotropic samarium-iron-nitrogen magnetic powder with sub-micron single crystal particles

[0076] The composition of the master alloy is the same as in Example 1, but C is added on this basis 5 , That is, the atomic percentage is Sm 8.5 Nd 1.5 Ce 1.0 Fe 76 Co 8 Nb 5 C 5 . The other process technology for manufacturing the magnetic powder is the same as in the first embodiment. When the interstitial atoms partially replace N with C, and the master alloy is added through the rapid-solidification flake technology, the Curie temperature and anisotropic field strength of the magnetic powder are significantly enhanced, as shown in Table 3. This is a powerful measure to improve the temperature performance of the magnetic powder.

[0077] table 3:

[0078] ingredient Tc(K) Ha(kOe) Example 1750120 Example 2780135

Embodiment 3

[0079] Example 3 Preparation of anisotropic samarium-iron-nitrogen magnetic powder with submicron single crystal particles

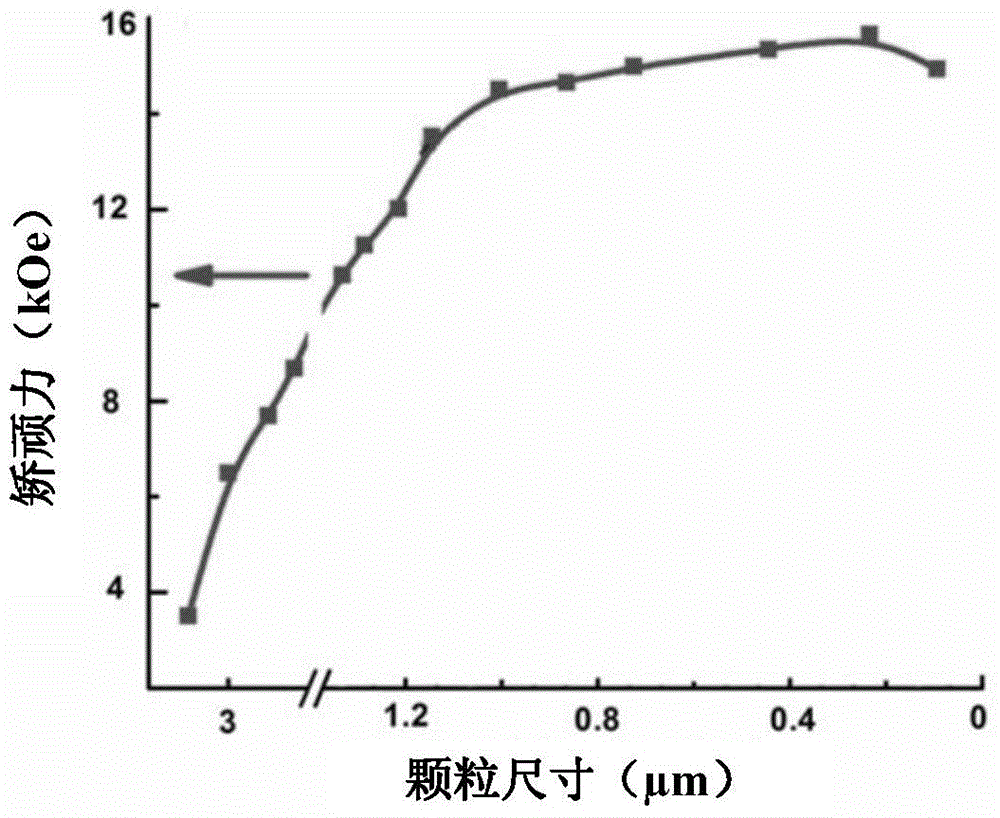

[0080] The composition of the master alloy is the same as in Example 1, but when the samarium-iron-nitrogen alloy is jet milled and / or ball milled, anisotropic samarium-iron-nitrogen single crystal particle magnetic powders with different average particle sizes can be obtained. The coercivity sensitivity depends on the magnetic powder. 的particle size.

[0081] Table 4:

[0082] The average particle size iHc(kOe) 3μm6.5 1.5μm9.5 1.0μm12.5 0.8μm14.0 0.6μm15.3 0.2μm 16.0

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com