Bismuth/carbon supercapacitor battery and preparation method thereof

A supercapacitor battery and carbon electrode technology, applied in the field of electrochemical energy storage, can solve problems such as no related reports on research and application, and achieve the effects of environmental friendliness, long cycle life and large electric capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Weigh a certain mass of Bi(NO 3 ) 3 ·5H 2 O, dissolved in 10ml of concentrated nitric acid solution, diluted with water, prepared into 0.5mol / L Bi(NO 3 ) 3 solution, set aside.

[0050] (2) 2.22g PVP, 20mL 0.5mol / L Bi(NO 3 ) 3 The solution was successively added into a 100mL round bottom flask, after mixing evenly, it was stirred at room temperature for 30min.

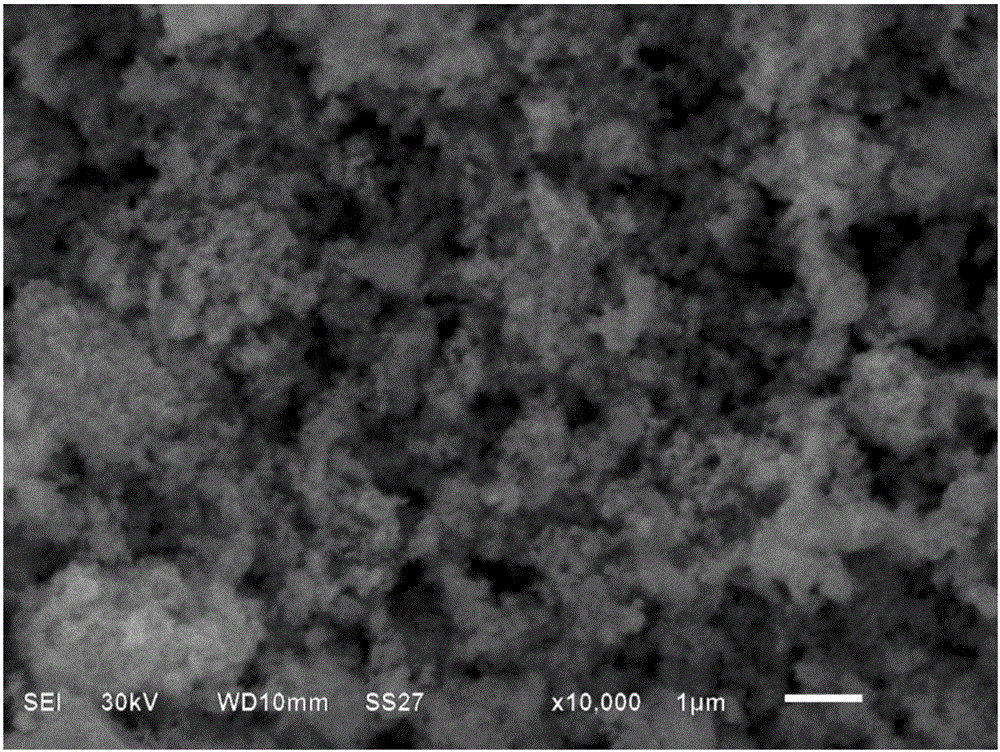

[0051] (3) According to the molar ratio of sodium borohydride and bismuth ions as 3:1, take a certain mass of sodium borohydride and dissolve it in 20ml deionized water to form a sodium borohydride solution. At room temperature, stir the sodium borohydride solution Add dropwise to the solution in step (2). After the dropwise addition, continue to stir for 5 minutes. Wash and filter the resultant with distilled water and ethanol for several times until the pH value is neutral, and put it in a vacuum drying oven at 90°C. After drying for 12 hours, the bismuth material was obtained.

[0052] (4) adopt J...

Embodiment 2

[0058] (1) Weigh 1.99g of bismuth citrate and dissolve it in 20ml of ethylene glycol solution.

[0059] (2) Add 0.5 g of tartaric acid and 2.0 g of sodium hydroxide to the solution in step (1) sequentially, mix well, and stir at room temperature for 30 min.

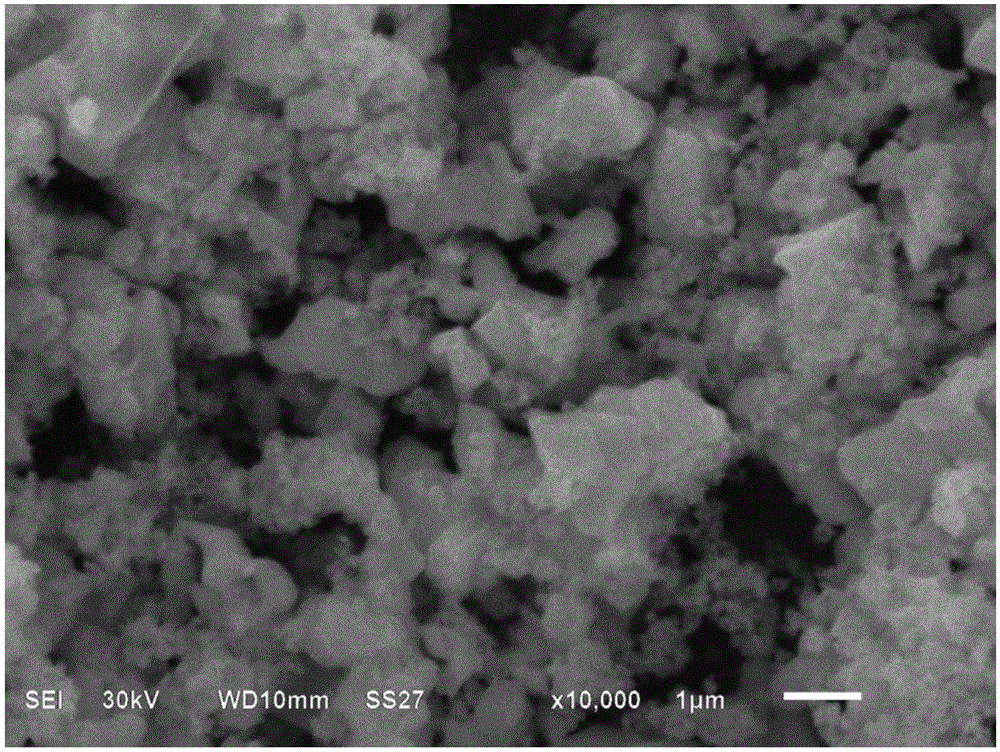

[0060] (3) by NaH 2 PO 2 and bismuth ion molar ratio is 80:1, weigh a certain mass of NaH 2 PO 2 Dissolve in 40ml deionized water to make NaH 2 PO 2 solution, at 90°C, NaH 2 PO 2 solution was added dropwise to the step (2) solution, after the dropwise addition was completed, the stirring was continued for 300 min until the solution changed from clarification to black, and the resultant was washed with distilled water and ethanol and suction filtered several times until the pH value was neutral. Put it into a vacuum drying oven and dry it at 80°C for 18 hours to obtain a bismuth material.

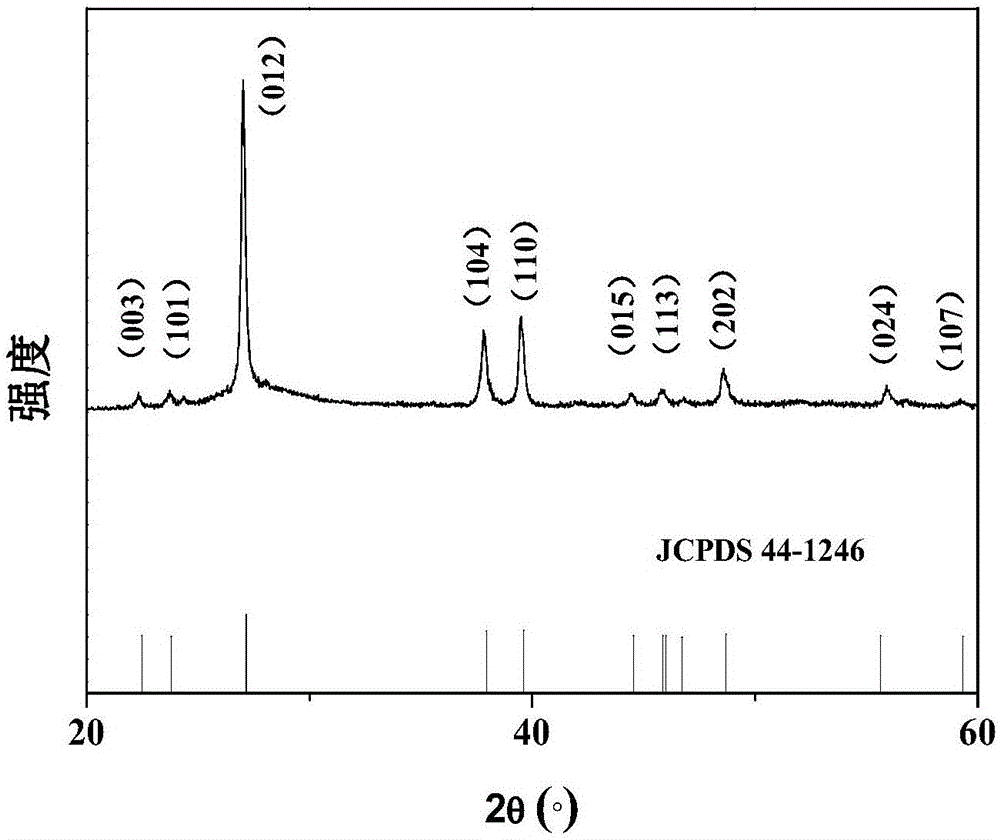

[0061] (4) adopt JEOLJEM-3010 type scanning electron microscope to test the bismuth powder material prepared by embodiment 2, ...

Embodiment 3

[0063] (1) Weigh a certain mass Bi 2 (SO 4 ) 3 , dissolved in 10mL of concentrated sulfuric acid solution, and prepared as 0.5mol / L Bi 2 (SO4) 3 solution, set aside.

[0064] (2) Add 0.05 g of sodium oleate into the solution in step (1), mix well, and stir at room temperature for 30 min.

[0065](3) According to the 80:1 molar ratio of hydrazine hydrate and bismuth ions, measure 80wt% hydrazine hydrate and dilute it into a solution of a certain concentration. At 90°C, add the hydrazine hydrate solution dropwise to step (2) while stirring. In the solution, after the dropwise addition, continue to stir for 120min until the solution turns from clear to black, wash and filter the resultant with distilled water and ethanol for several times until the pH value is neutral, and put it in a vacuum drying oven at 70°C Dry for 24 hours to obtain bismuth material.

[0066] (4) Preparation of bismuth electrode and carbon electrode: according to the mass percent of bismuth or carbon m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com