Nanometer ferromanganese oxidation composite electrode materials for super capacitor and preparation method thereof

A technology for supercapacitors, composite electrodes, applied in hybrid capacitor electrodes, nanotechnology for materials and surface science, hybrid/electric double-layer capacitor manufacturing, etc., which can solve electrochemical performance limitations, application limitations, low specific capacity, etc. problem, to achieve the effect of improving electrochemical performance, high specific capacity, and increasing pore volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

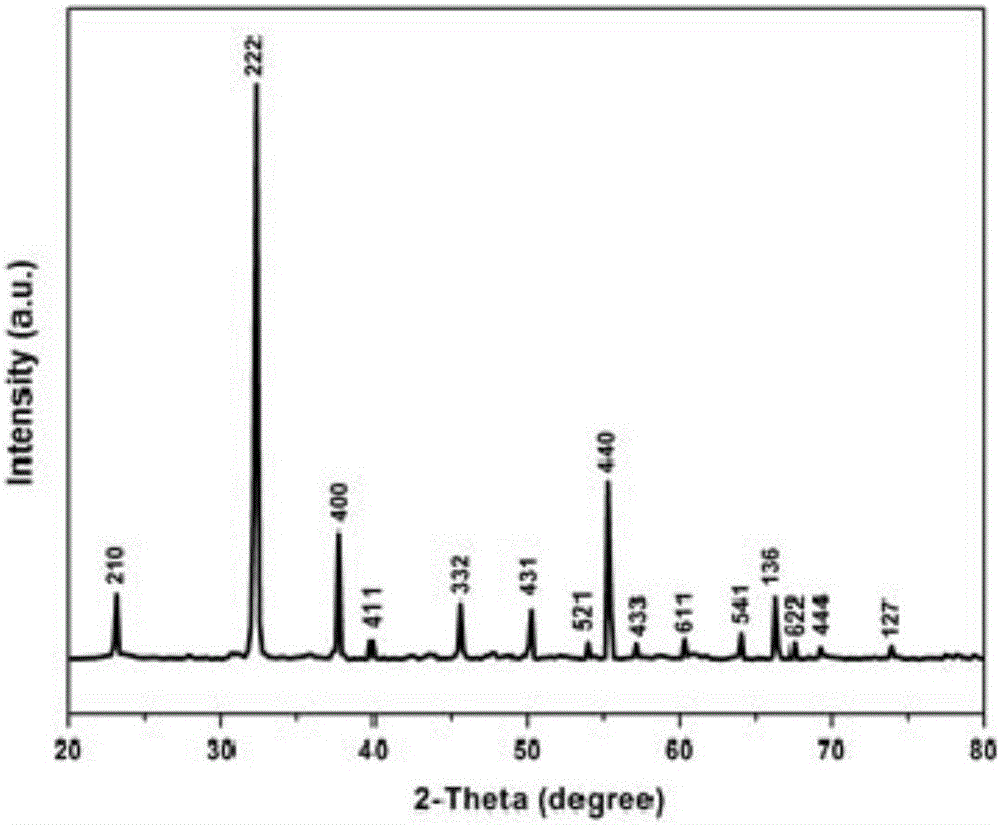

[0023] Dissolve 5g of manganese nitrate and 4.15g of ferric nitrate in deionized water, then add 2g of citric acid to form a uniformly dispersed solution, then add an appropriate amount of ammonia water to adjust the pH of the solution to neutral, and then heat at 120°C for 2.5 hours to make the solution gradually Turned into a viscous gel and eventually into lumps. After drying at 180° C. for 5 hours, it was placed in a tube furnace and calcined at 500° C. for 2 hours to obtain a nano-ferromanganese oxide composite electrode material. Such as figure 1 As shown, the nano-ferromanganese oxide composite electrode material has a pure phase cubic crystal structure, and its specific surface area is 23.15m 2 / g, the pore volume is 0.00971cm 3 / g.

[0024] The prepared composite electrode material, binder PVDF, and conductive agent acetylene black were uniformly mixed according to a mass ratio of 8:1:1, and then a positive electrode was made. In the same way, activated carbon is ...

Embodiment 2

[0026] Dissolve 5g of manganese nitrate and 5g of ferric nitrate in deionized water, then add 2g of citric acid to form a uniformly dispersed solution, then add an appropriate amount of ammonia water to adjust the pH of the solution to neutral, then heat at 120°C for 2.5 hours to make the solution gradually become Into a viscous gel, and finally into a block. After drying at 180° C. for 5 hours, it was placed in a tube furnace and calcined at 500° C. for 2 hours to obtain a nano-ferromanganese oxide composite electrode material. The specific surface area of the nano-manganese iron oxide composite electrode material is 23.22m 2 / g, the pore volume is 0.00975cm 3 / g.

[0027] The prepared composite electrode material, binder PVDF, and conductive agent acetylene black were uniformly mixed according to a mass ratio of 8:1:1, and then a positive electrode was made. In the same way, activated carbon is used as the negative electrode active material, the binder PVDF, and the con...

Embodiment 3

[0029] Dissolve 5g of manganese nitrate and 6g of ferric nitrate in deionized water, then add 2g of citric acid to form a uniformly dispersed solution, then add an appropriate amount of ammonia water to adjust the pH of the solution to neutrality, and then heat at 120°C for 2.5 hours to make the solution gradually become Into a viscous gel, and finally into a block. After drying at 180° C. for 5 hours, it was placed in a tube furnace and calcined at 500° C. for 2 hours to obtain a nano-ferromanganese oxide composite electrode material. The specific surface area of nano-manganese iron oxide composite electrode material is 23.09m 2 / g, the pore volume is 0.00962cm 3 / g.

[0030] The prepared composite electrode material, binder PVDF, and conductive agent acetylene black were uniformly mixed according to a mass ratio of 8:1:1, and then a positive electrode was made. In the same way, activated carbon is used as the negative electrode active material, the binder PVDF, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com