A kind of polypyrrole/graphite carbon nitride nanocomposite material and preparation method thereof

A technology of graphitic carbon nitride and nanocomposite materials, which is applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. Good redox reversibility, improved dispersibility and formability, good symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 1g of graphite-type carbon nitride into a three-necked round-bottomed flask equipped with 25ml of deionized water, stir magnetically for 30min under nitrogen protection, and disperse, then add 1g of pyrrole to the dispersion and stir at 0°C for 30min, then add oxidant 10mlAPS The solution (containing APS3.4g) was added dropwise to the above mixture, and reacted at 0°C for 10h. The resulting product was repeatedly washed with deionized water, and vacuum-dried for 24 h at 60° C. to obtain a polypyrrole / graphite carbon nitride nanocomposite.

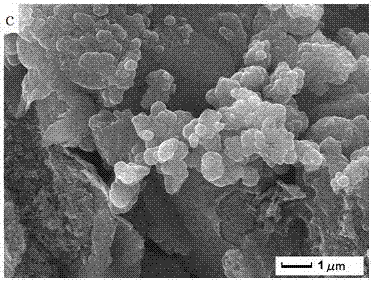

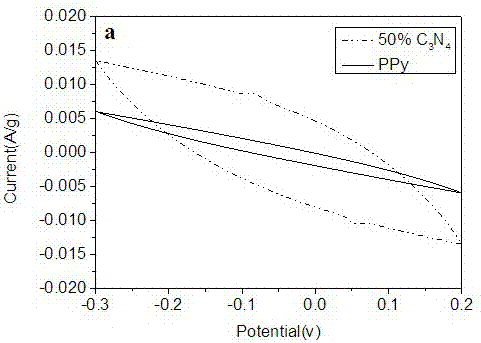

[0024] figure 1 It is the scanning electron microscope picture of the polypyrrole / graphite carbon nitride nanocomposite material prepared in embodiment 1, it can be seen from the figure that polypyrrole particles are deposited on the surface of graphite carbon nitride or intercalated in g-C 3 N 4 between the sheets; the cyclic voltammetry curve of the prepared polypyrrole / graphite carbon nitride nanocomposite is as follows fi...

Embodiment 2

[0026] Add 0.2539g of graphite-type carbon nitride into a three-necked round-bottomed flask equipped with 25ml of deionized water, and magnetically stir for 30min under nitrogen protection to disperse, then add 1g of pyrrole to the dispersion and stir at 0°C for 30min, then add the oxidant 10ml of APS solution (containing APS3.4g) was added dropwise to the above mixture, and reacted at 0°C for 10h. The resulting product was repeatedly washed with deionized water, and vacuum-dried for 24 h at 60° C. to obtain a polypyrrole / graphite carbon nitride nanocomposite.

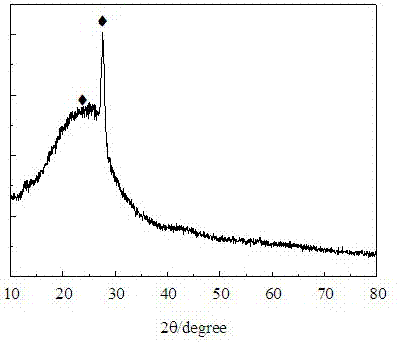

[0027] The X-ray diffraction pattern of the prepared polypyrrole / graphite carbon nitride nanocomposite is as follows: image 3 As shown, it can be seen from the figure that the peak at 2θ=24.2° is the weaker characteristic diffraction peak of PPy, and the characteristic diffraction peak at 2θ=27.4° belongs to the characteristic diffraction peak of pure graphite carbon nitride, which may be caused by conjugated caused ...

Embodiment 3

[0029] Add 0.4287g of graphite-type carbon nitride into a three-neck round-bottomed flask equipped with 25ml of deionized water, and magnetically stir for 30min under nitrogen protection to disperse, then add 1g of pyrrole to the dispersion and stir at 0°C for 30min, then add the oxidant 10ml of APS solution (containing APS3.4g) was added dropwise to the above mixture, and reacted at 0°C for 10h. The resulting product was repeatedly washed with deionized water, and vacuum-dried for 24 h at 60° C. to obtain a polypyrrole / graphite carbon nitride nanocomposite.

[0030] The infrared spectrogram of gained polypyrrole / graphite carbon nitride nanocomposite material is as Figure 4 As shown, the characteristic absorption peak of polypyrrole / graphite-type carbon nitride nanocomposites is similar to that of pure PPy, and the addition of graphite-type carbon nitride makes the characteristic absorption peak from PPy 1549 cm -1 ,1457 cm -1 , 1045 cm -1 A blue shift occurs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com