Polyvinyl chloride functional masterbatch, functionalization method and application of masterbatch

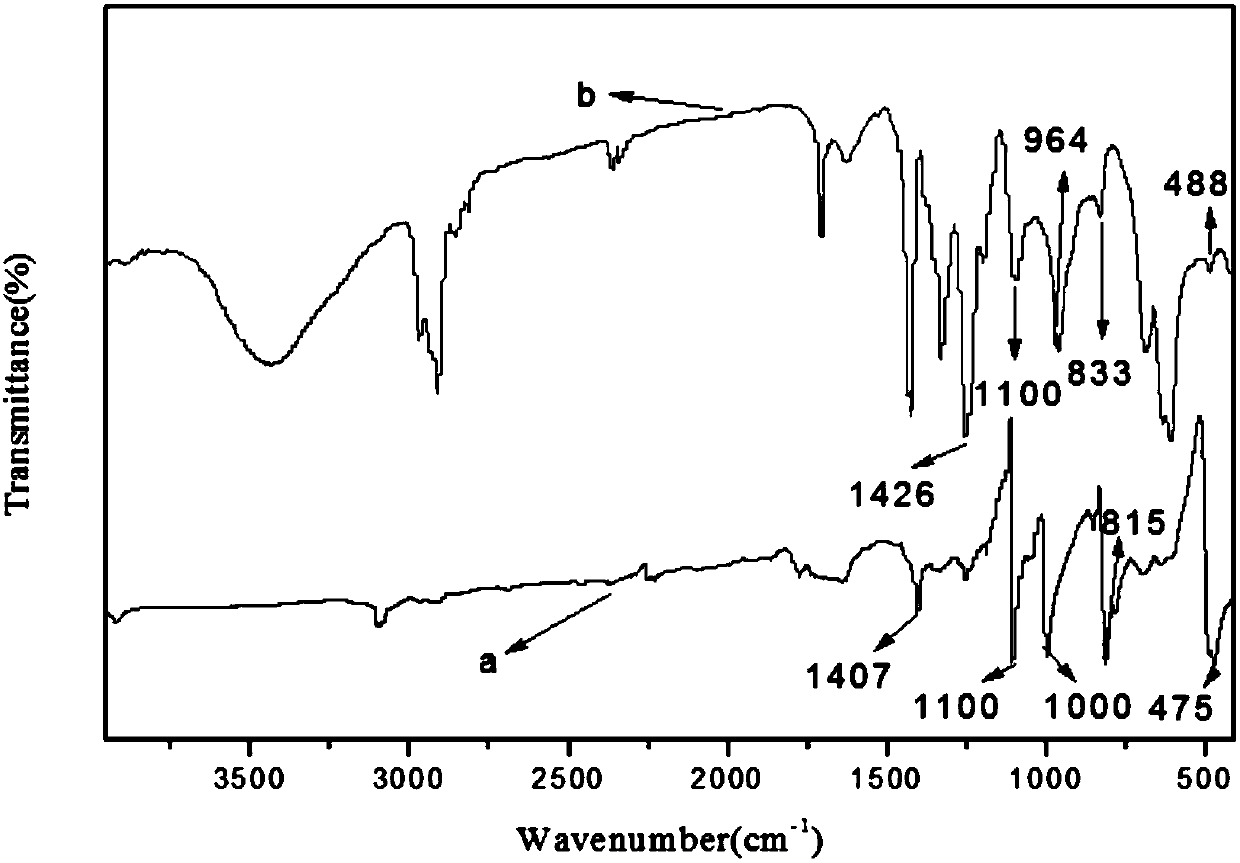

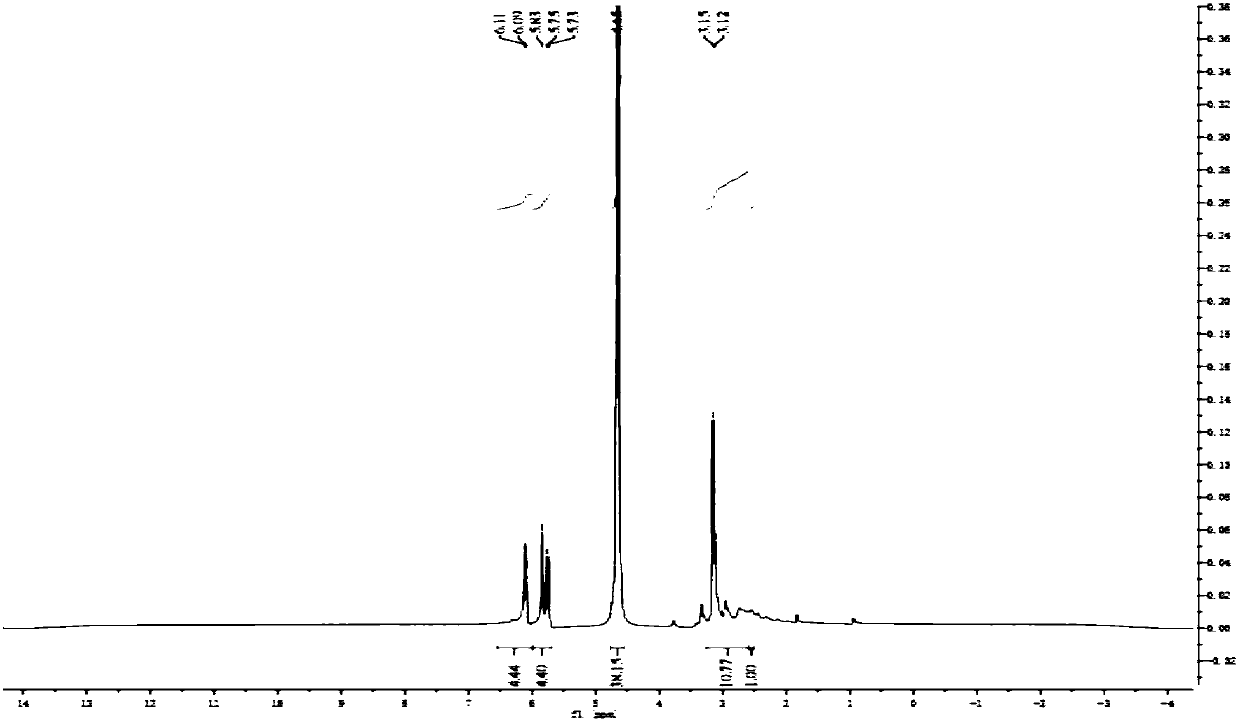

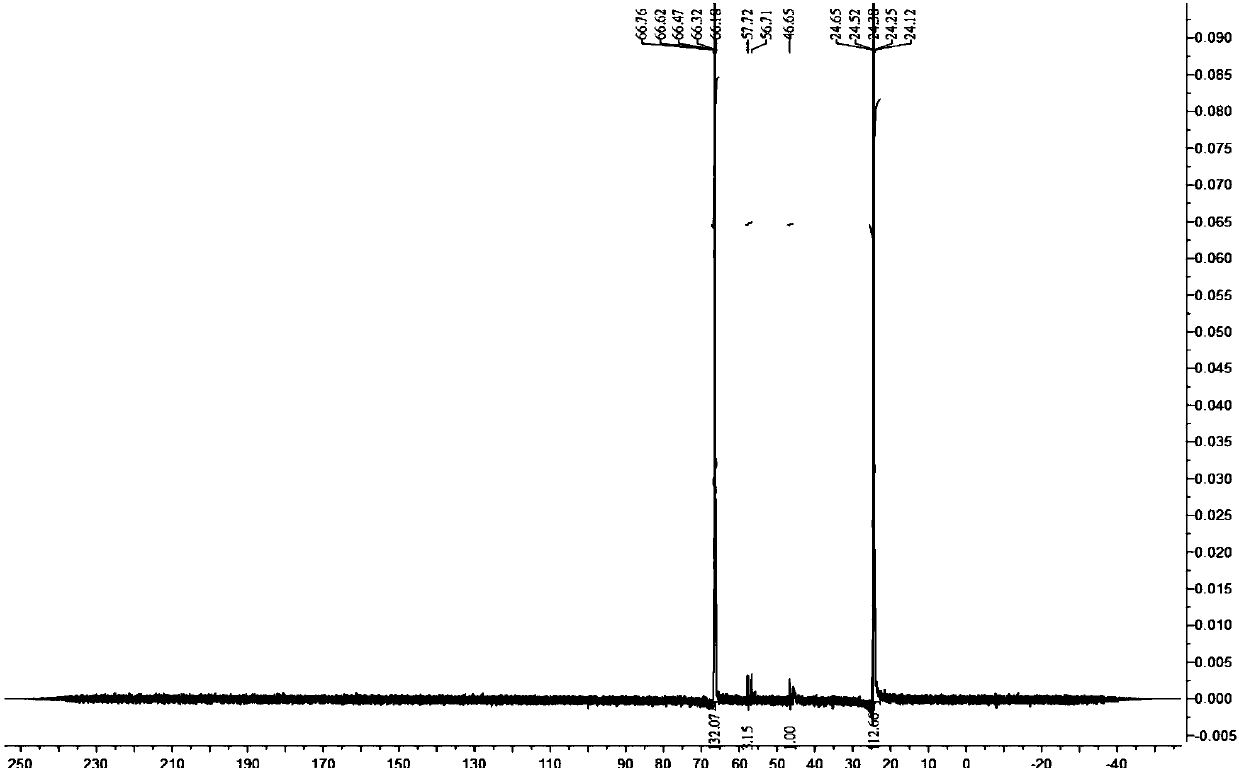

A polyvinyl chloride, functionalized technology, applied in the field of ferrocene functionalized polyvinyl chloride, can solve the problem of releasing a large amount, achieve the effects of inhibiting release, improving thermal stability, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: With tetrahydrofuran as solvent, add 100g PVC, 50g ferrocene and 4.5g AlCl respectively 3 , using microwave irradiation heating, grafting reaction in boiling tetrahydrofuran solution, reaction 20 min, microwave irradiation power of 500W, to obtain polyvinyl chloride functional masterbatch, grafting rate of 2.92%.

Embodiment 2

[0033] Embodiment 2: With tetrahydrofuran as solvent, add 100g PVC, 50g ferrocene and 4.5g AlCl respectively 3 , using oil bath heating, grafting reaction was carried out in boiling tetrahydrofuran solution for 20 minutes to obtain polyvinyl chloride functionalized masterbatch with a grafting rate of 0.84%.

Embodiment 3

[0034] Embodiment 3: 100g PVC and 50g ferrocene are mixed according to, then add 4.5g AlCl 3 and 3g of dibutyltin dilaurate, ground and mixed evenly, placed in an autoclave for grafting reaction, 170°C, and reacted for 2 hours to obtain polyvinyl chloride functionalized masterbatch with a grafting rate of 3.42%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com