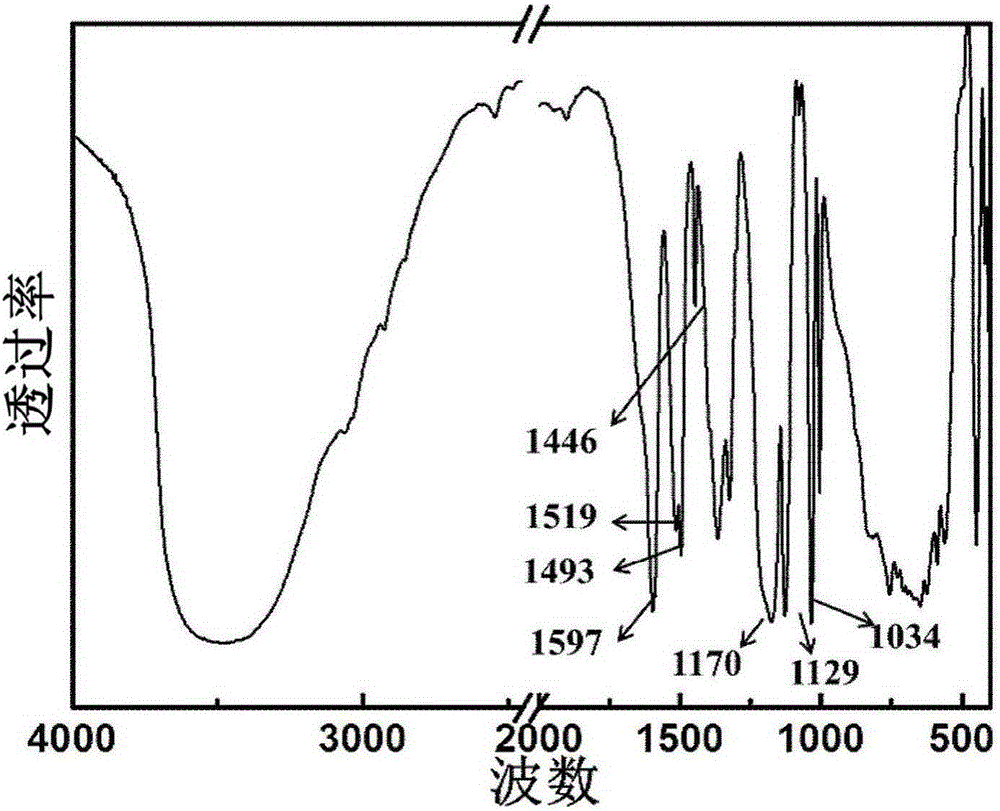

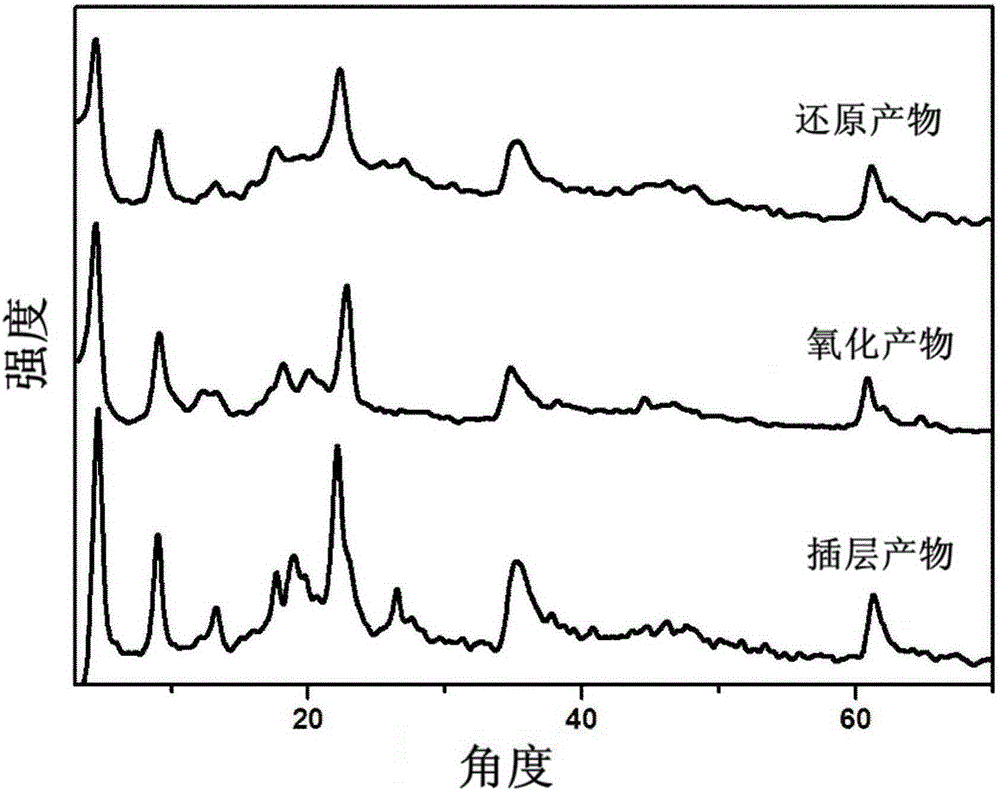

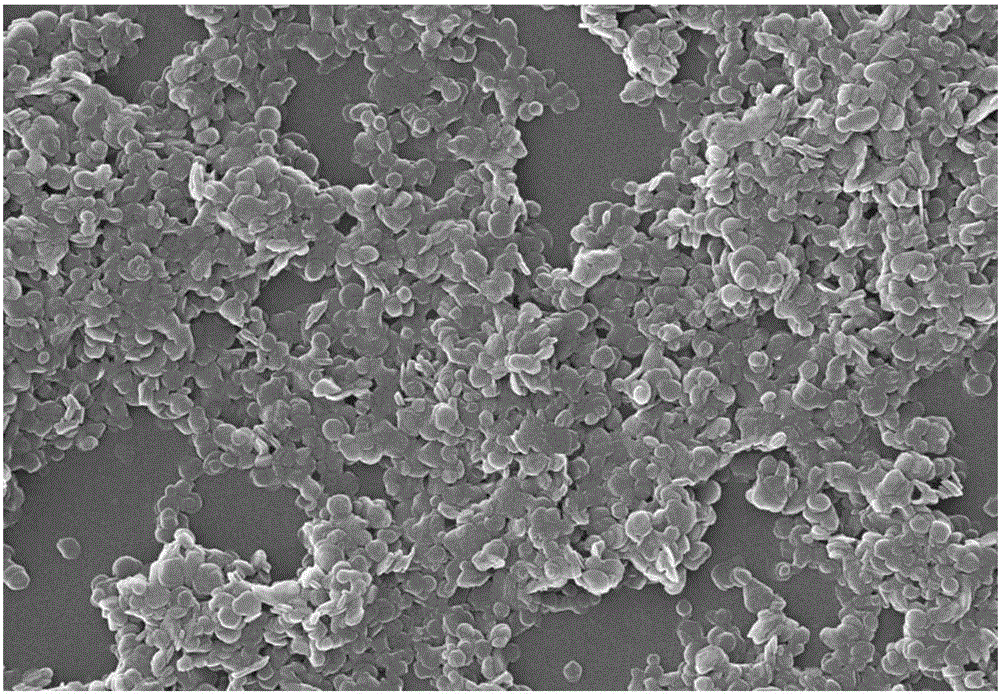

A kind of preparation method and application of diphenylamine sulfonate intercalation hydrotalcite material

A technology of diphenylamine sulfonate and diphenylamine sulfonate, which is applied in the application fields of diphenylamine sulfonate intercalated hydrotalcite materials, redox color materials and electrochromic materials, and can solve the problems of unreported color change performance, etc. Achieving good redox reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Weigh 0.769gMg(NO 3 ) 2 ·6H 2 O, 0.563gAl(NO 3 ) 3 9H 2 O, 0.407g sodium diphenylamine sulfonate is dissolved in 50ml to remove CO 2 In deionized water, a mixed solution A, Mg 2+ / Al 3+ The molar ratio is 2:1, Mg 2+ The concentration is 0.06M, and the mixed solution is poured into a four-necked flask;

[0029] 2. Weigh 0.8g NaOH and dissolve in 40ml to remove CO 2 In deionized water, pass the NaOH solution through a constant pressure funnel, and slowly add it dropwise to the four-necked flask containing the mixed solution A until the pH value is 10 under the condition of nitrogen protection, and stir for 20 minutes to obtain the slurry B, which is transferred to 100ml The high-pressure reactor was placed in a 130°C oven for 24 hours;

[0030] 3. Use the reaction products to remove CO 2 , deionized water and ethanol and centrifuged and washed 6 times until the washing solution was colorless, and the filter cake obtained by centrifugation was vacuum-dried at...

Embodiment 2

[0034] 1. Weigh 0.769gMg(NO 3 ) 2 ·6H 2 O, 0.563gAl(NO 3 ) 3 9H 2 O, 0.407g sodium diphenylamine sulfonate is dissolved in 50ml to remove CO 2 In deionized water, a mixed solution A, Mg 2+ / Al 3+ The molar ratio is 2:1, Mg 2+ The concentration is 0.06M, and the mixed solution is poured into a four-necked flask;

[0035] 2. Weigh 0.8g NaOH and dissolve in 40ml to remove CO 2 In deionized water, pass the NaOH solution through a constant pressure funnel, and slowly add it dropwise to a four-neck flask containing solution A until the pH value is 9.5 under nitrogen protection, and stir for 40 minutes to obtain slurry B, which is transferred to a 100ml The high-pressure reactor was placed in an oven at 110°C for 20 hours;

[0036] 3. Use the reaction products to remove CO 2 , deionized water and ethanol, and centrifuged and washed 6 times until the washing solution was colorless, and the filter cake obtained by centrifugation was vacuum-dried at 60° C. for 6 hours to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com