Ultrafiltration/adsorption bi-functional film and preparation method thereof

A dual-function, ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of difficult recovery of adsorbents, secondary pollution, etc., achieve high reuse rate, prevent secondary pollution, etc. Less pollution, easy to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

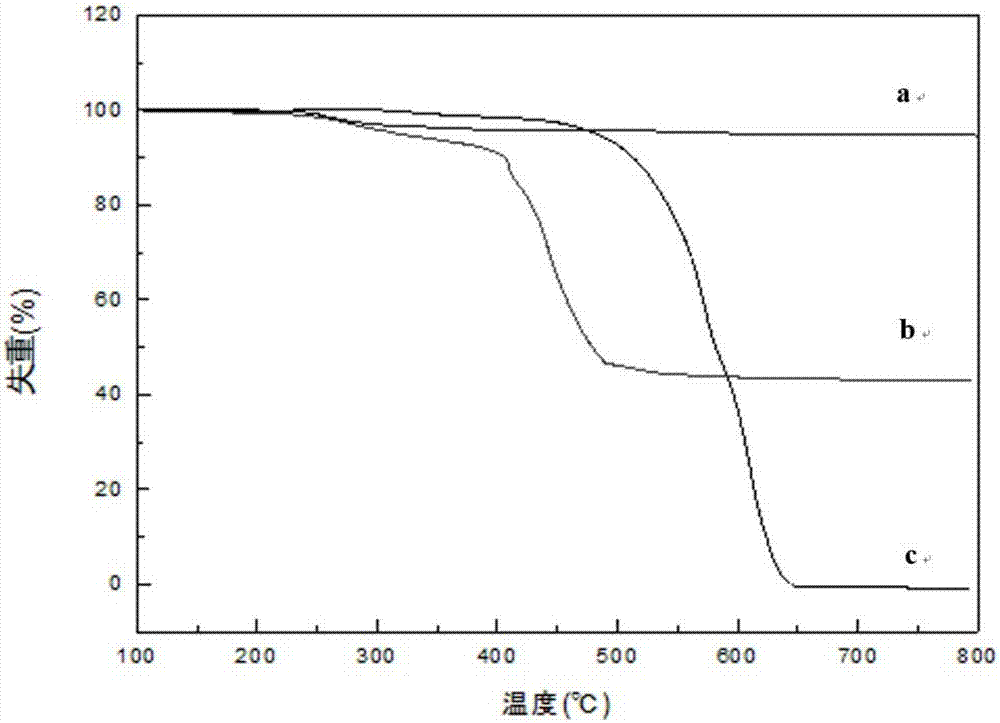

[0023] According to the mass ratio of polyethyleneimine, N,N-dimethylformamide, polyethersulfone and polyvinylpyrrolidone K30 as 0.6:75.4:16:8, weigh PEI and DMF solvents in conical flasks, place in in the oven until the PEI is completely dissolved. Then add PES and PVP K30, magnetically stir until homogeneous, heat in a constant temperature oil bath at 65°C, and dissolve under stirring at 500r / min for 6 hours. After it was completely dissolved, it was taken out from the oil bath, cooled to room temperature, and allowed to stand for 12 hours for defoaming to obtain a homogeneous casting solution.

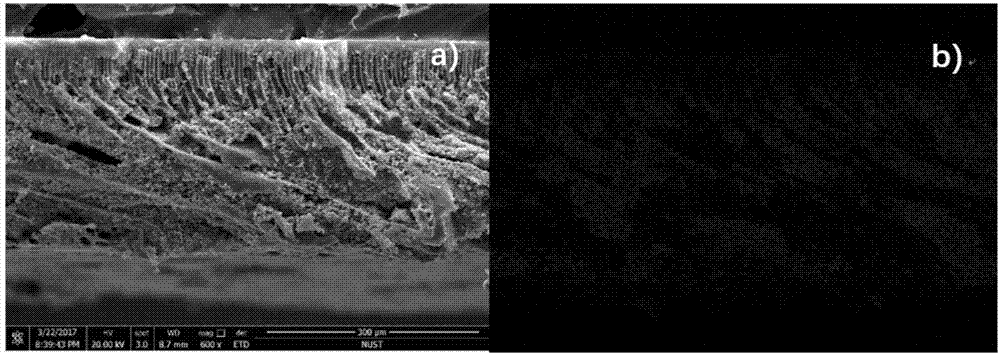

[0024] Quickly pour the casting liquid onto a glass plate placed in an oven at 100°C for 1 hour, then use a film scraper to evenly coat the prepared casting liquid on the surface of the glass plate, and quickly place it in a 55°C gel bath ( The gel bath adopts water) to perform phase inversion to form a membrane; the obtained open-pore basement membrane is stored in deionized water...

Embodiment 2

[0027] According to the mass ratio of polyethyleneimine, N,N-dimethylformamide, polyethersulfone and polyvinylpyrrolidone K30 as 0.6:75.4:13:11, weigh PEI and DMF solvents in conical flasks, place in in the oven until the PEI is completely dissolved. Then add PES and PVP K30, magnetically stir until homogeneous, heat in a constant temperature oil bath at 65°C, and dissolve under stirring at 500r / min for 6 hours. After it was completely dissolved, it was taken out from the oil bath, cooled to room temperature, and allowed to stand for 12 hours for defoaming to obtain a homogeneous casting solution.

[0028] Quickly pour the casting liquid onto a glass plate placed in an oven at 100°C for 1 hour, then use a film scraper to evenly coat the prepared casting liquid on the surface of the glass plate, and quickly place it in a 55°C gel bath ( The gel bath adopts water) to perform phase inversion to form a membrane; the obtained open-pore basement membrane is stored in deionized wate...

Embodiment 3

[0030] Fix the membrane in Example 1 in the filter device, filter the sewage under the pressure of 0.010MPa, the As concentration of the influent is 96.3ppb, after the membrane penetrates, soak the bifunctional membrane in the NaOH solution of 0.5M to carry out To regenerate, repeat this operation again for three cycles. Figure 4 It can be seen that after being regenerated twice, the capacity of the dual-function ultrafiltration membrane to treat sewage is about 80% of that of the original membrane, which shows that the dual-function membrane has a good reuse rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com