Preparation methods of different carbon fiber/cobalt hydroxide electrodes and solid-liquid composite electrode systems

A technology of cobalt hydroxide and composite electrodes, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of low energy density, achieve high solubility, good safety, and easy charge transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

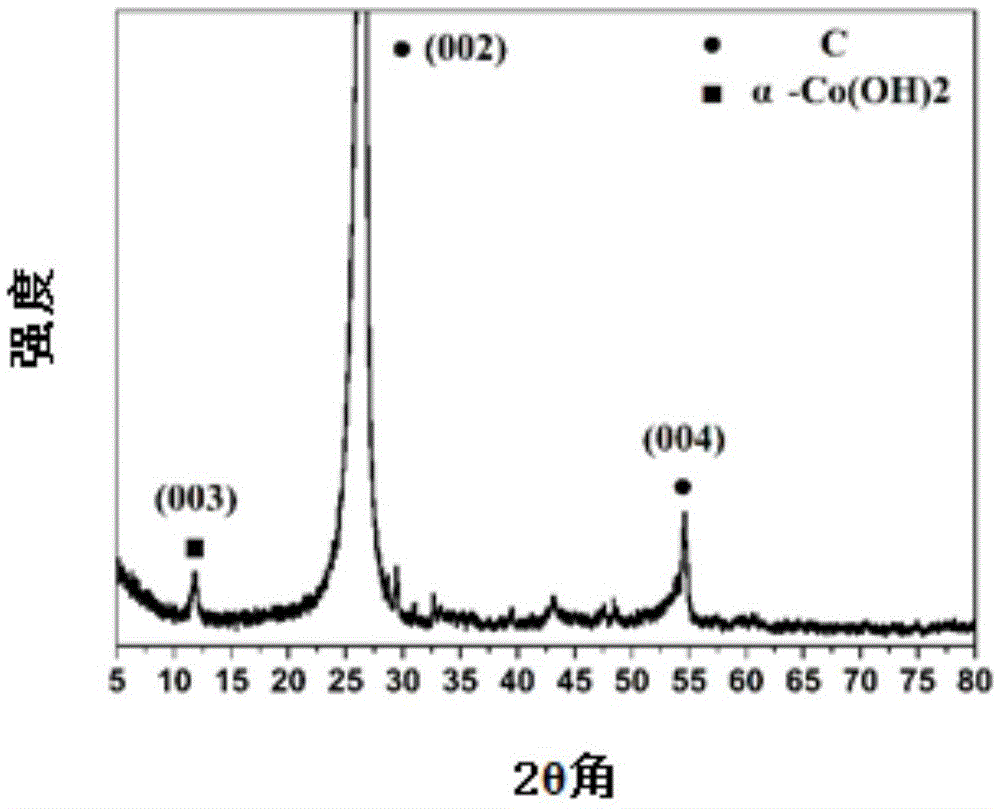

[0062] C: the preparation of cobalt hydroxide in the present invention adopts constant potential or constant current electrochemical deposition technology to grow cobalt hydroxide on the treated carbon fiber material substrate, and the main steps are as follows:

[0063] 1) The temperature of the constant temperature water bath is raised to a predetermined temperature to maintain a constant temperature of the electrochemical deposition system.

[0064] 2) Adjust the required deposition potential or current, and conduct electrodeposition according to the predetermined deposition amount; after the electrodeposition is completed, turn off the power, take out the working electrode, wash it with deionized water several times, and dry it in an oven to obtain carbon fiber Materials / Cobalt Hydroxide Solid Electrode. The above-mentioned different carbon fiber materials / cobalt hydroxide solid electrodes were weighed with a micro balance.

[0065] D: Prepare a certain concentration of K...

Embodiment 1

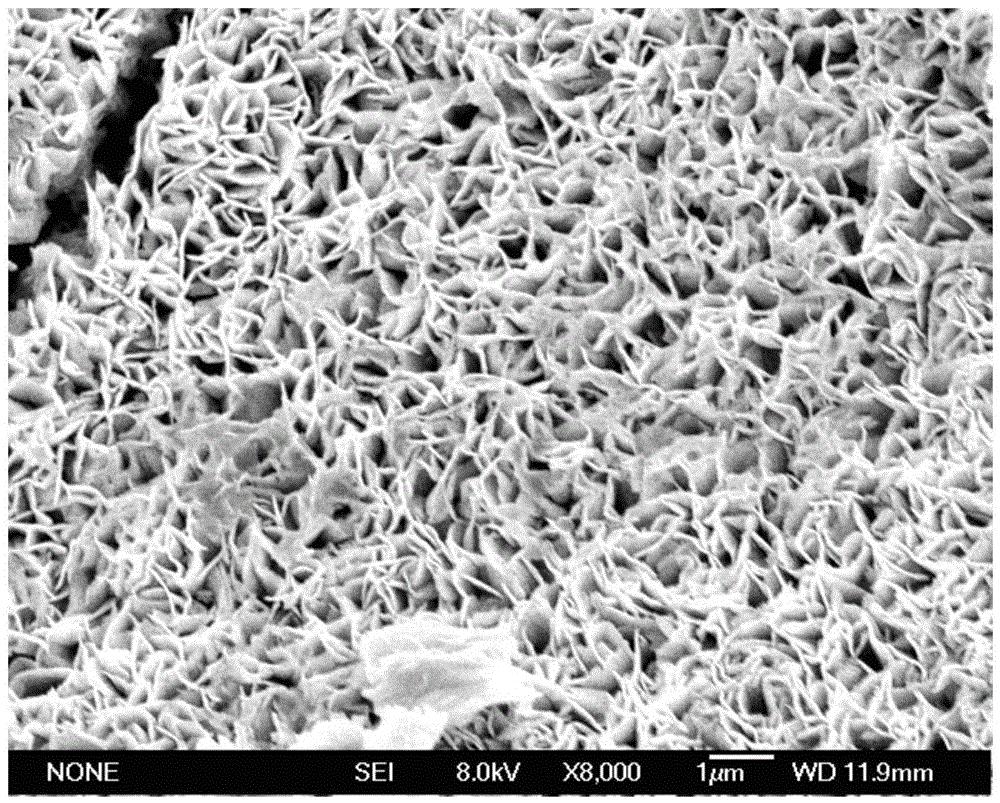

[0075] 1) Cut a 2mm thick carbon felt into a rectangle with an area of 1cmx2cm.

[0076] 2) Soak the rectangular sample in a beaker filled with acetone solution, let it stand for 2 hours, and sonicate it in the solution for 10 minutes; wash the sample with ethanol solution, soak it in a beaker filled with ethanol solution, and let it stand for 2 After 1 hour, ultrasonic in the solution for 10 min; rinse the sample with deionized water, soak it in a beaker filled with deionized water, let it stand for 2 hours, and ultrasonic in the solution for 10 min. After repeated rinsing with deionized water, dry in an oven at 60°C for 18 hours. After cooling down, the mass of the sample was weighed with a microbalance.

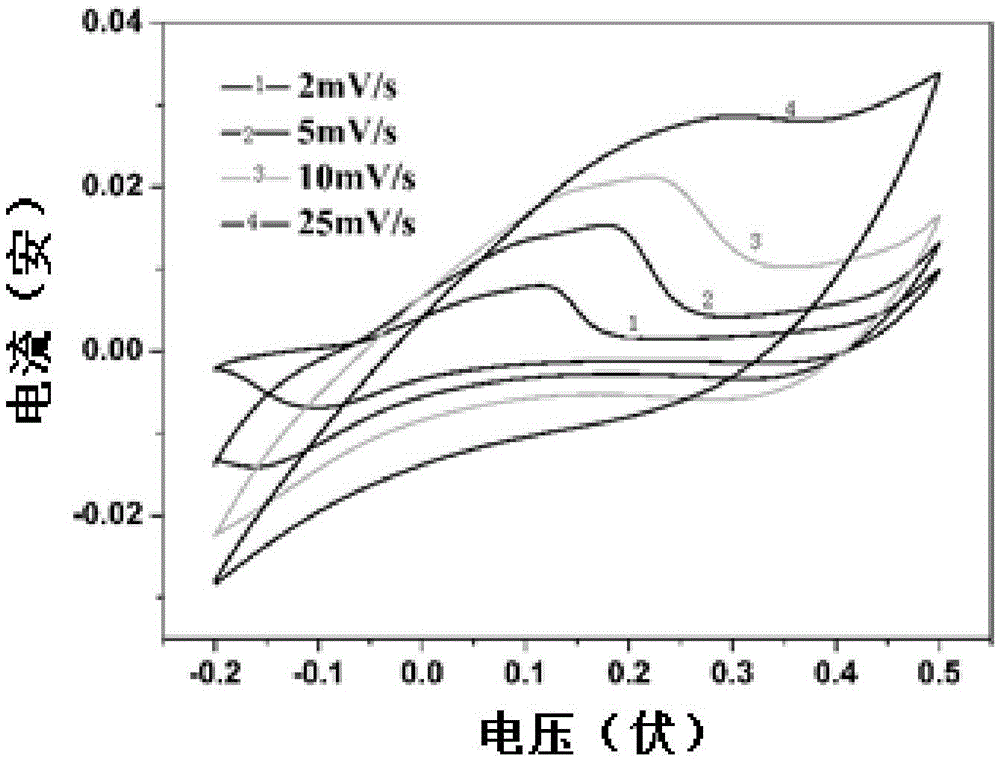

[0077] 3) The voltage of the potentiostat was adjusted to -0.9V, and the electrodeposition was carried out by the cathodic deposition method. Electrodeposition adopts a three-electrode system, the above-mentioned treated carbon felt is the working electrode, the counte...

Embodiment 2

[0081] In Step 1) of Example 1, the carbon felt is replaced by carbon cloth, and the remaining steps are the same as in Example 1. After electrochemical testing, when the current density is 2A / g, the specific capacitance can reach 1055F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com