Novel inflame-retardant aluminum alloy cable

An aluminum alloy and cable technology, applied in the direction of insulated cables, metal/alloy conductors, cables, etc., can solve the problems of heavy weight, poor corrosion resistance, poor resistance, etc., and achieve excellent electrical and mechanical properties, flame retardant properties. The effect of superior, outstanding flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

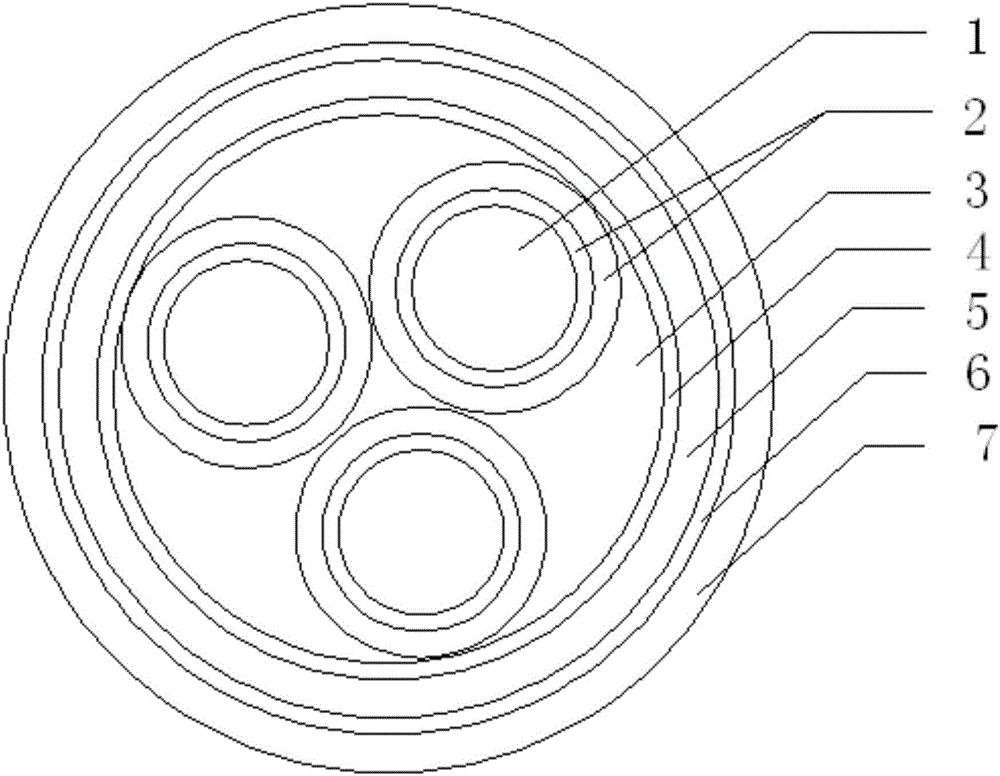

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, the new flame-retardant aluminum alloy cable of this embodiment includes at least one wire core, and the structure of a single wire core is as follows: it includes a conductor 1, and the periphery of the conductor 1 is wrapped with an insulating layer 2, and the insulating layer 2 is irradiated. Cross-linked polyethylene and low-smoke halogen-free polyolefin insulating material are double-layer co-extruded; the core is provided with a filler 3; the periphery of the core and the filler 3 are wrapped with a wrapping layer 4 and an inner lining layer 5 in turn , metal armor layer 6, outer sheath 7.

[0027] Conductor 1 is boron aluminum alloy material. It has the characteristics of high electrical conductivity, high creep resistance and compaction, high tensile strength and good yield strength.

[0028] Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com