Hard platinum alloy and preparation method thereof

A platinum alloy and metal technology, which is applied in the field of hard platinum alloy and its preparation, can solve the problems of low hardness of platinum-palladium alloy, falling stones and turquoise, difficult gas removal, etc., to eliminate tissue defects and residual stress, improve strength, and prevent deformation and cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

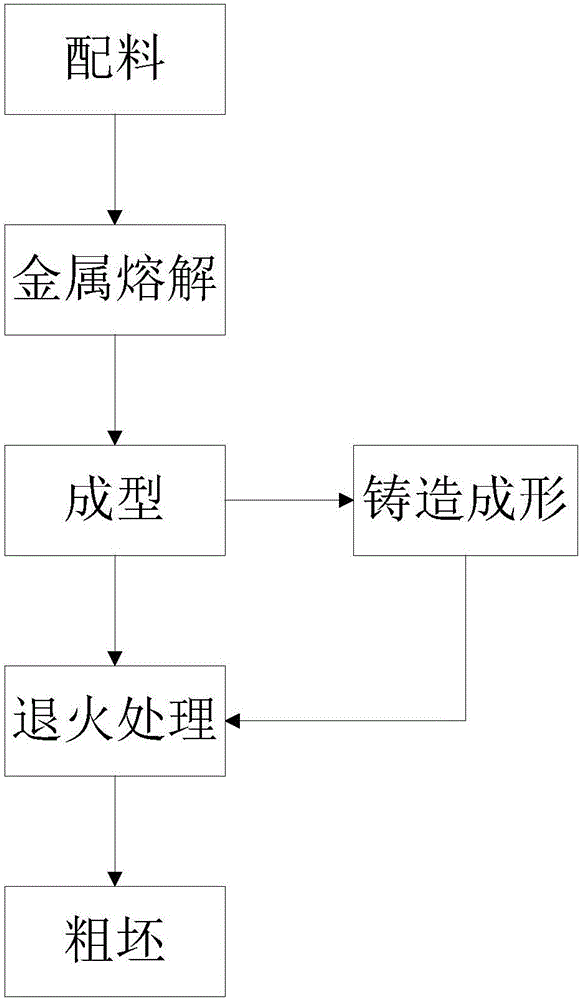

[0023] Such as figure 1 , the present embodiment discloses a hard platinum alloy containing 89.9-95.99wt% platinum, 4.0-9.6wt% cobalt and 0.01-0.5wt% X, where X is selected from tungsten, iridium, ruthenium, A kind of in zirconium, osmium, chromium, rhodium, titanium, molybdenum; The preparation method of this hard platinum alloy comprises the steps:

[0024] The metal raw materials in the platinum alloy are compounded according to weight percentage of 90.2wt% platinum, 9.6wt% cobalt and 0.2wt% X. Metal cobalt has excellent physical, chemical and mechanical properties. Metal cobalt is an important raw material for the production of materials such as high temperature resistance, corrosion resistance, high strength and strong magnetism; therefore, metal cobalt is added to platinum alloys to increase the strength of platinum alloys. In this embodiment, X is made of ruthenium, which can increase the hardness of the platinum alloy. Put the weighed platinum into an alumina crucibl...

Embodiment 2

[0029] The devices, process parameters and process flow included in this embodiment are basically the same as in Example 1, except that the weight percentage of platinum in the platinum alloy is 95.2%, the weight percentage of cobalt is 4.6% and the weight percentage of ruthenium is 0.2% . Compared with Example 1, in this example, the weight percentage of platinum is increased by 5%, and the weight percentage of cobalt is reduced by 5%, which increases the stability of the platinum alloy and strengthens the firmness of the diamond setting.

Embodiment 3

[0031] The devices, process parameters and process flow included in this embodiment are basically the same as in Example 1, except that the weight percentage of platinum in the platinum alloy is 95.8%, the weight percentage of cobalt is 4.0% and the weight percentage of ruthenium is 0.2% . Compared with Example 2, in this example, the weight percentage of platinum is increased by 0.6%, and the weight percentage of cobalt is reduced by 0.6%, which further increases the stability of the platinum alloy and strengthens the firmness of the platinum alloy in the mosaic process. sex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com