Preparation and application of supported iron-based metal organic framework oxidation sweetening catalyst

An iron-based metal, organic framework technology, used in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, refining with oxygenated compounds, etc., can solve problems such as easy shedding, and achieve operability The effect of strong, simple synthesis process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

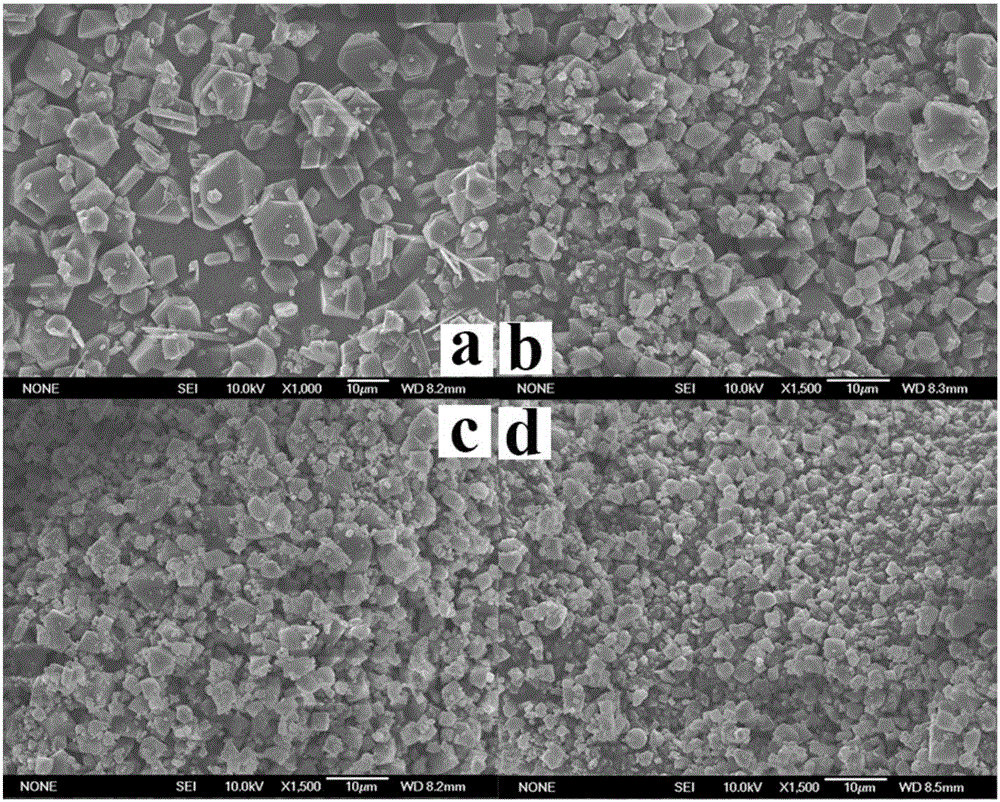

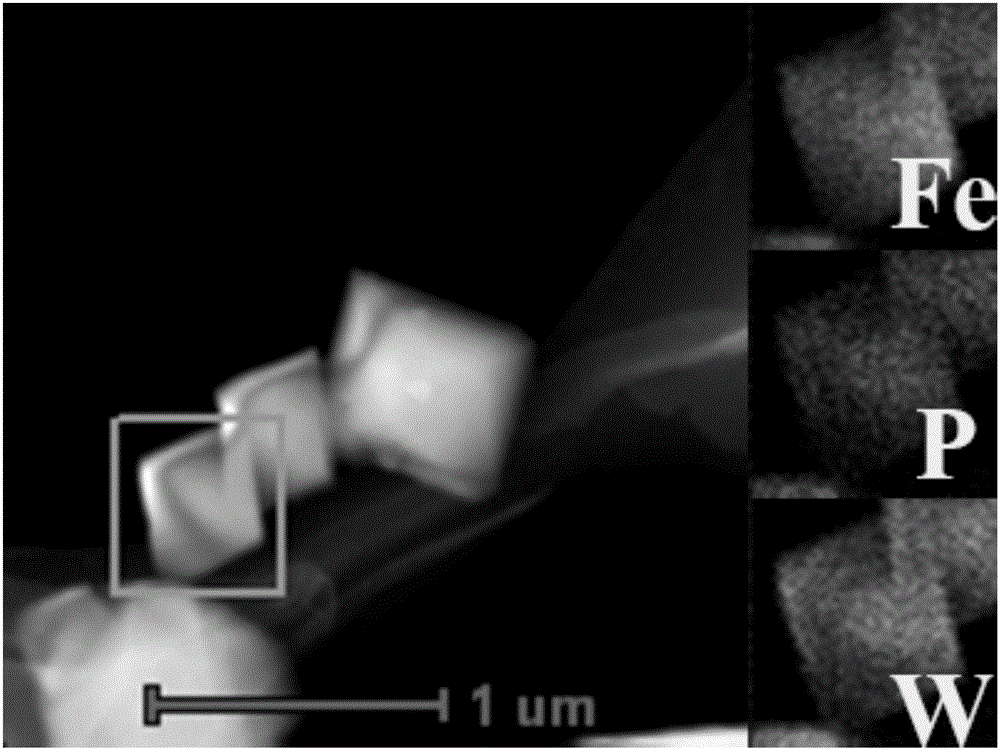

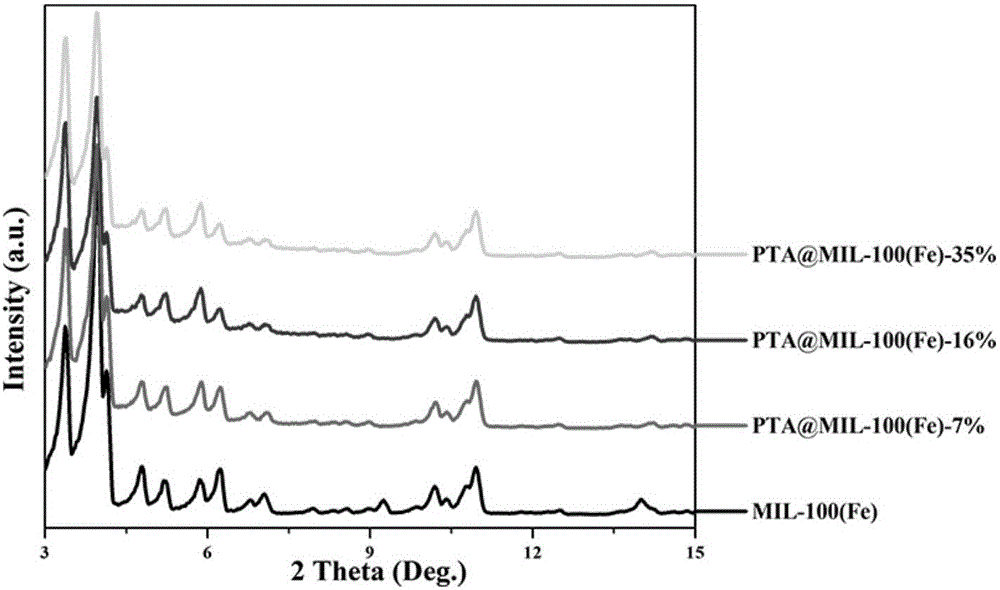

[0045] (1) Preparation of PTA@MIL-100(Fe)

[0046] Hydrothermal method, with iron powder (0.45g), trimesic acid (1.13g), hydrofluoric acid (0.71mL, 22.5M), nitric acid (0.32mL, 15M), phosphotungstic acid (1.44g, 2.88g, 5.76g) and deionized water (47mL) as raw materials, sonicated for 20min to obtain a uniformly mixed solution, and kept in an oven at 160°C for 24h, the obtained orange solid was washed three times with water and ethanol, and placed in an oven at 70°C After drying overnight, PTA@MIL-100(Fe)-7%, PTA@MIL-100(Fe)-16%, and PTA@MIL-100(Fe)-35% were obtained. Among them, 7%, 16% and 35% are the percentages of phosphotungstic acid in the total mass of the catalyst respectively.

[0047] (2) Preparation of blank material MIL-100(Fe)

[0048] Hydrothermal method, with iron powder (0.45g), trimesic acid (1.13g), hydrofluoric acid (0.71mL, 22.5M), nitric acid (0.32mL, 15M) and deionized water (47mL) as raw materials, ultrasonic Treat for 20 minutes to obtain a uniformly ...

Embodiment 2

[0055] Performance evaluation of extraction catalytic oxidation desulfurization of PTA@MIL-100(Fe) catalyst:

[0056] (1) Dibenzothiophene was selected as the probe molecule to study the performance of the prepared catalyst. Take 2 mL of dibenzothiophene / n-heptane mixed solution with a sulfur content of 1000 mass ppm and place it in a reaction tube, then add 2 mL of acetonitrile, and then add 15 mg of catalyst MIL-100(Fe), PTA@MIL-100(Fe)-7% , PTA@MIL-100(Fe)-16% or PTA@MIL-100(Fe)-35%. After adding 10 μL of hydrogen peroxide, place it in an air bath reaction mold at 80° C. to start the reaction, and react for 1 h. After catalysis, the catalytic activities of the four catalysts were 0%, 32%, 70%, 28%, respectively. It shows that when the loading of phosphotungstic acid is low, the catalytic activity increases with the loading of phosphotungstic acid, but when the loading of the catalyst is too high, the catalytic activity decreases instead.

[0057] (2) The PTA@MIL-100(Fe)-...

Embodiment 3

[0064] Performance evaluation of extraction catalytic oxidation desulfurization of PTA@ZIF-8 catalyst:

[0065] (1) Utilize the optimum condition in embodiment 2, promptly reaction condition is: temperature is 70 ℃, O / S is 4, and reaction times is 1h, and the quality of catalyst is 23mg (the amount of active component phosphotungstic acid and PTA@ MIL-100(Fe)-16% is the same). The activity of the catalyst was 13%.

[0066] (2) Extended substrate. The catalytic desulfurization reaction of 1000mass ppm benzothiophene and 4,6-dimethyldibenzothiophene was carried out under optimal conditions, but the reaction time was extended to 24h, and the catalytic activities were 10% and 23%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com