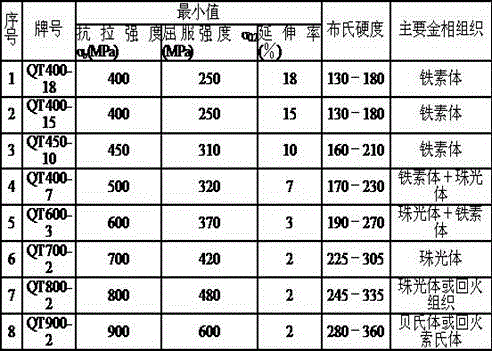

Substitutive QT400 aluminum alloy flywheel brake caliper material and gravity casting forming method thereof

A gravity casting and brake caliper technology, which is applied in the field of replacing QT400 aluminum alloy flywheel brake caliper materials and its preparation, can solve the problems of high inertia, easy corrosion, and impact on life of ductile iron, and achieve alloy grain size refinement, The effect of rounded shape and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] 1. An aluminum alloy flywheel brake caliper housing that replaces QT400. The weight percentage of the material is: Mn: 0.3%, Cd: 0.05%, Cu: 5.3%, Si: 1.3%, Mg: 0.5%, TiC0.05% , [Cd(CN) 4 ] 2- : 0.01%, LiH: 0.15%, the balance is aluminum Al;

[0118] 2. Preparation method: melt → pouring → cavity tipping → filling and solidification → solid solution → aging

[0119] (1) Melt pouring temperature ≥ 690°C;

[0120] (2) Mold preheating temperature ≥ 400°C;

[0121] (3) Filling time ≤ 25s;

[0122] (4) Cavity tipping speed ≥ 30 degrees / second, holding time ≥ 3min;

[0123] (5) Heat treatment state: T6 - solid solution plus complete artificial aging;

[0124] 3. The microstructure index of the product: the metallographic structure is equiaxed crystal, the average grain size is 120μm, and the number of combined phases (T+θH) in the grain is 5 / [μm] 2 ;

[0125] 4. Mechanical properties of castings: tensile strength 440Mpa, yield strength 336 Mpa, elongation after fract...

Embodiment 2

[0127] 1. An aluminum alloy flywheel brake caliper housing that replaces QT400. The weight percentage of the material is: Mn: 0.5%, Cd: 0.06%, Cu: 6.8%, Si: 1.8%, Mg: 0.55%, Ti: 0.03% , [Cd(CN) 4 ] 2- : 0.02%, LiH: 0.12%, the balance is aluminum Al;

[0128] 2, preparation method: with embodiment 1;

[0129] 3. Product microstructure index: the metallographic structure is equiaxed grain, the average grain size is 115μm, and the number of (T+θH) combination phases in the grain is 4 / [μm] 2 ;

[0130] 4. Mechanical properties of castings: tensile strength is 435Mpa, yield strength is 320Mpa, elongation after fracture is 12.5%, and Brinell hardness is 120.

Embodiment 3

[0132]1. An aluminum alloy flywheel brake caliper housing that replaces QT400 The weight percentage of the material composition is: Mn: 0.5%, Cd: 0.06%, Cu: 6.0%, Si: 0.8%, [Cd(CN) 4 ] 2- : 0.45%, the balance is aluminum Al;

[0133] 2, preparation method: with embodiment 1;

[0134] 3. The microstructure index of the product: the metallographic structure is equiaxed grain, the average grain size is 115μm, and the number of combined phases (T+θH) in the grain is 3-4 / [μm] 2 ;

[0135] 4. Mechanical properties of castings: tensile strength is 425Mpa, yield strength is 310Mpa, elongation after fracture is 12.5%, and Brinell hardness is 110.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com