Praseodymium-ytterbium co-doped zirconium gallium sulfide glass up-conversion luminescent material as well as preparation method and application thereof

A technology of luminescent materials and co-doping, which is applied in the fields of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the above-mentioned praseodymium-ytterbium co-doped zirconium-gallium sulfide glass up-conversion luminescent material comprises the following steps:

[0029] Step S11, according to ZrS-Ga 2 S 3 -R 2 S: xPr 3+ ,yYb 3+ The stoichiometric ratio of each element weighs ZrO, Al 2 o 3 , Na 2 O, Pr 2 o 3 and Ho 2 o 3 Powder, wherein, R is at least one of lithium element, sodium element, potassium element, rubidium element and cesium element, x is 0.01-0.06, and y is 0.01-0.04.

[0030] In this step, the ZrS, Ga 2 S 3 , R 2 S, Pr 2 S 3 and Yb 2 S 3 The molar ratio of each component of the powder (0.57-0.8): (0.12-0.3): (0.03-0.06): (0.005-0.03): (0.005-0.02).

[0031] In this step, preferably, x is 0.03 and y is 0.02.

[0032] Step S13, mixing the powder weighed in step S11 evenly to obtain a precursor.

[0033] In this step, the powder is ground in a corundum bowl for 20 minutes to 60 minutes to obtain a uniformly mixed precursor, ...

Embodiment 1

[0042] Choose powder with a purity of 99.99%, ZrS, Ga 2 S 3 , Li 2 S, Pr 2 S 3 and Yb 2 S 3 The molar ratio of each component of the powder is 0.2:0.05:0.015:0.01. Grind it in a corundum mortar for 40 minutes to make it evenly mixed, then burn it in a muffle furnace at 950°C for 3 hours, then cool it to 200°C and keep it for 2 hours. hours, then take it out with the furnace cooling to room temperature to obtain bulk material, after pulverization, the general chemical formula can be obtained as 0.7ZrS-0.2Ga 2 S 3 -0.05Li 2 S: 0.03Pr 3+ , 0.02Yb 3+ Up-converting phosphors.

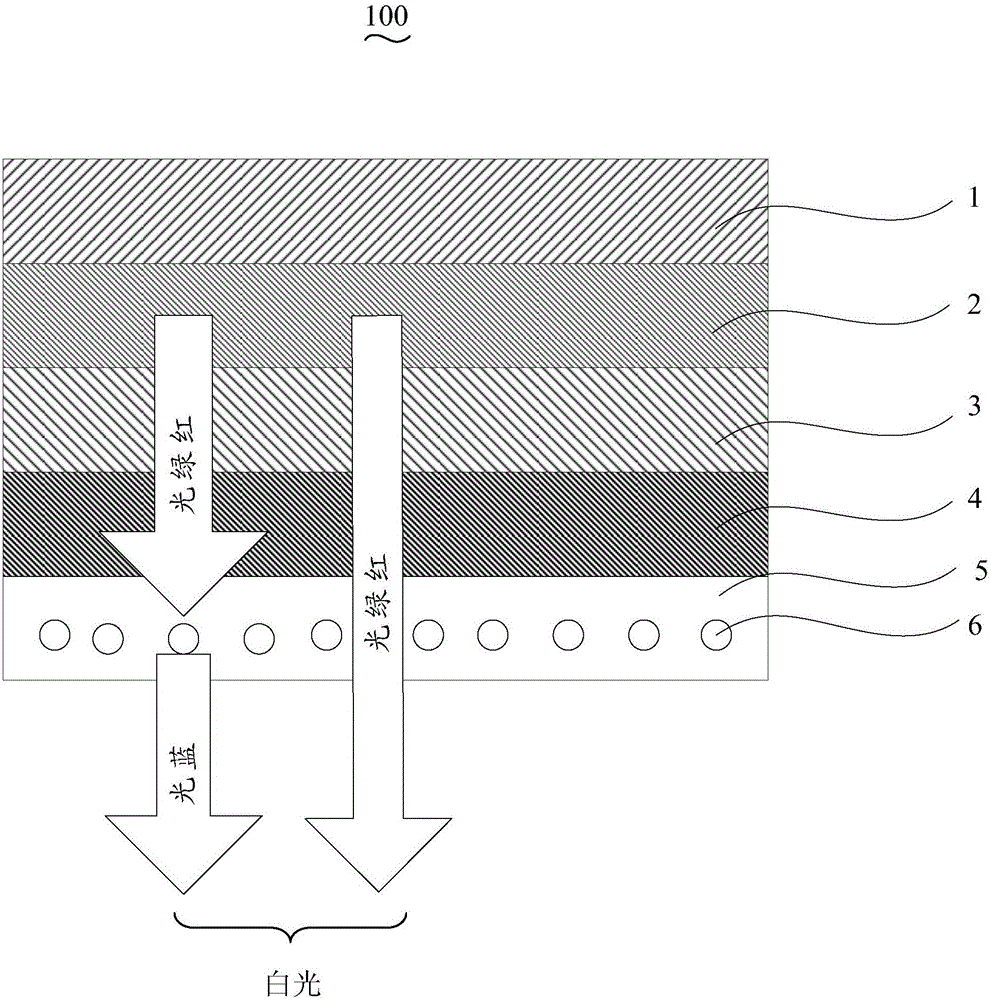

[0043] The process of making organic light-emitting diodes

[0044] The sequentially stacked substrate 1 uses soda-lime glass, the cathode 2 uses a metal Ag layer, and the organic light-emitting layer 3 uses Ir(piq)2(acac), the Chinese name is bis(1-phenyl-isoquinoline)(acetylacetonate) iridium (III), the transparent anode 4 uses indium tin oxide ITO, and the transparent encapsulation layer 5 is ...

Embodiment 2

[0049] Choose powder with a purity of 99.99%, ZrS, Ga 2 S 3 , Li 2 S, Pr 2 S 3 and Yb 2 S 3 The molar ratio of each component of the powder is 0.8:0.12:0.06:0.005:0.005, grind it in a corundum mortar for 20 minutes to make it evenly mixed, then burn it in a muffle furnace at 800°C for 3 hours, and then cool it to 250 Keep warm at ℃ for 0.5 hours, and then take it out after cooling to room temperature with the furnace to obtain a bulk material, which can be crushed to obtain a general chemical formula of 0.8ZrS-0.12Ga 2 S 3 -0.06Li 2 S: 0.01Pr 3 up-converting phosphors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Excitation wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com