Method for plating TC4 titanium alloy threaded surface with copper

A thread surface, titanium alloy technology, applied in the field of copper plating on the TC4 titanium alloy thread surface, can solve the problems of high chemical activity of titanium elements, complex preparation process, poor bonding force, etc., to avoid the risk of serious environmental pollution, and the process is stable and reliable , Good anti-sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

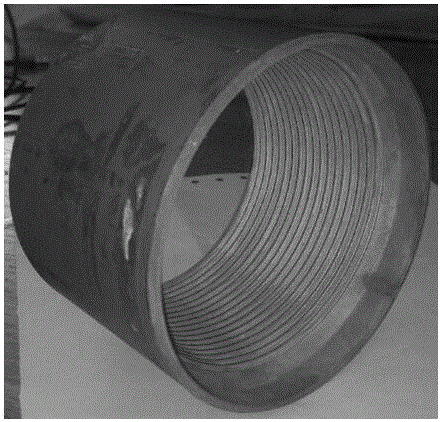

[0059] Copper-plated internal thread surface for TC4 titanium alloy 3 1 / 2" oil pipe coupling

[0060] Solution formula: ① Alkali washing solution: NaOH 75g / L; NaOH 3 PO 4 20g / L ②Pickling solution: HF 100ml / L; HNO 3 300ml / L; distilled water 600 ml / L ③Activation solution: Na 2 Cr 2 o 7 180 g / L; HF 50ml / L ④ Plating solution: CuSO 4 • 5H 2 O 150 g / L; H 2 SO 4 60ml / L ⑤passivation solution: CrO 3 80 g / L; NaCl 1.0 g / L; H 2 SO 4 25ml / L.

[0061] Implementation: see Figure 7 , including the following steps, ①alkali washing: place the workpiece in an alkali washing solution with a temperature of 65°C and soak for 15 minutes; ②water washing: rinse the workpiece after alkali washing with running water; ③acid washing: place the workpiece after washing Soak in pickling solution at room temperature for 2 minutes to carry out surface corrosion treatment; ④ Washing: Rinse the pickled workpiece with running water; ⑤ Activation treatment: Soak the washed workpiece in an activ...

Embodiment 2

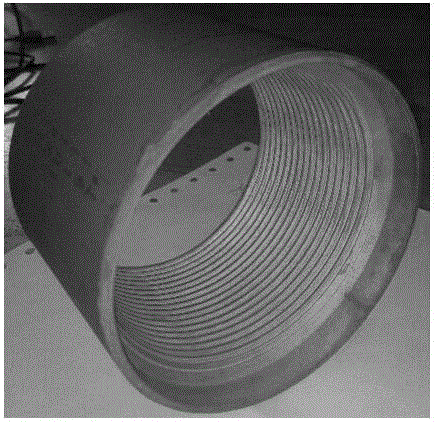

[0064] Copper-plated internal thread surface for TC4 titanium alloy 3 1 / 2" oil pipe coupling

[0065] Solution formula: ① Alkali washing solution: NaOH 85g / L; NaOH 3 PO 4 22.5g / L ②Pickling solution: HF 150ml / L; HNO 3 350 ml / L; distilled water 500 ml / L ③Activation solution: Na 2 Cr 2 o 7 210 g / L; HF 65ml / L ④ Plating solution: CuSO 4 • 5H 2 O 180 g / L; H 2 SO 4 70ml / L ⑤passivation solution: CrO 3 85 g / L; NaCl 1.5 g / L; H 2 SO 4 27.5ml / L.

[0066] Implementation: see Figure 7 , including the following steps, ①alkali washing: place the workpiece in an alkali washing solution with a temperature of 70°C and soak for 12 minutes; ②water washing: rinse the workpiece after alkali washing with running water; ③acid washing: place the workpiece after washing Soak in pickling solution at room temperature for 1.5 minutes to carry out surface corrosion treatment; ④ Washing: Rinse the pickled workpiece with running water; ⑤ Activation treatment: Soak the washed workpiece in an...

Embodiment 3

[0069] Copper-plated internal thread surface for TC4 titanium alloy 3 1 / 2" oil pipe coupling

[0070] Solution formula: ① Alkali washing solution: NaOH 100g / L; NaOH 3 PO 4 25g / L ②Pickling solution: HF 200ml / L; HNO 3 400 ml / L; distilled water 400 ml / L ③Activation solution: Na 2 Cr 2 o 7 250 g / L; HF 80ml / L ④ Plating solution: CuSO 4 • 5H 2 O 200 g / L; H 2 SO 4 80ml / L ⑤passivation solution: CrO 3 90 g / L; NaCl 2.0 g / L; H 2 SO 4 30ml / L.

[0071] Implementation: see Figure 7 , including the following steps, ①alkali washing: place the workpiece in an alkali washing solution with a temperature of 80°C and soak for 10 minutes; ②water washing: rinse the workpiece after alkali washing with running water; ③acid washing: place the workpiece after washing Soak in pickling solution at room temperature for 1 minute to carry out surface corrosion treatment; ④Water washing: Rinse the pickled workpiece with running water; ⑤Activation treatment: Soak the washed workpiece in an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com