Automobile hub bearing sealing ring and preparation method thereof

A technology for bearing seals and automobile hubs, which is applied in the field of auto parts processing, can solve problems such as inability to withstand low temperature, seal rings cannot withstand temperature, and no manufacturing process, so as to ensure mold release performance, improve ozone resistance, and benefit rubber materials. stored effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

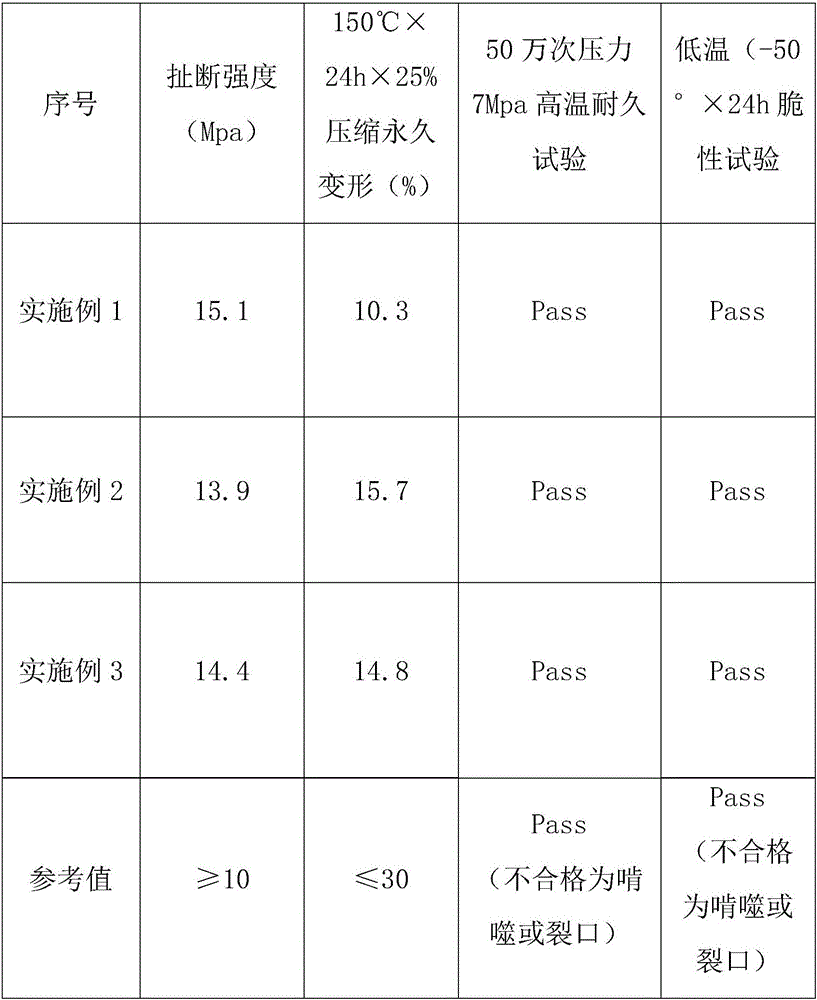

Embodiment 1

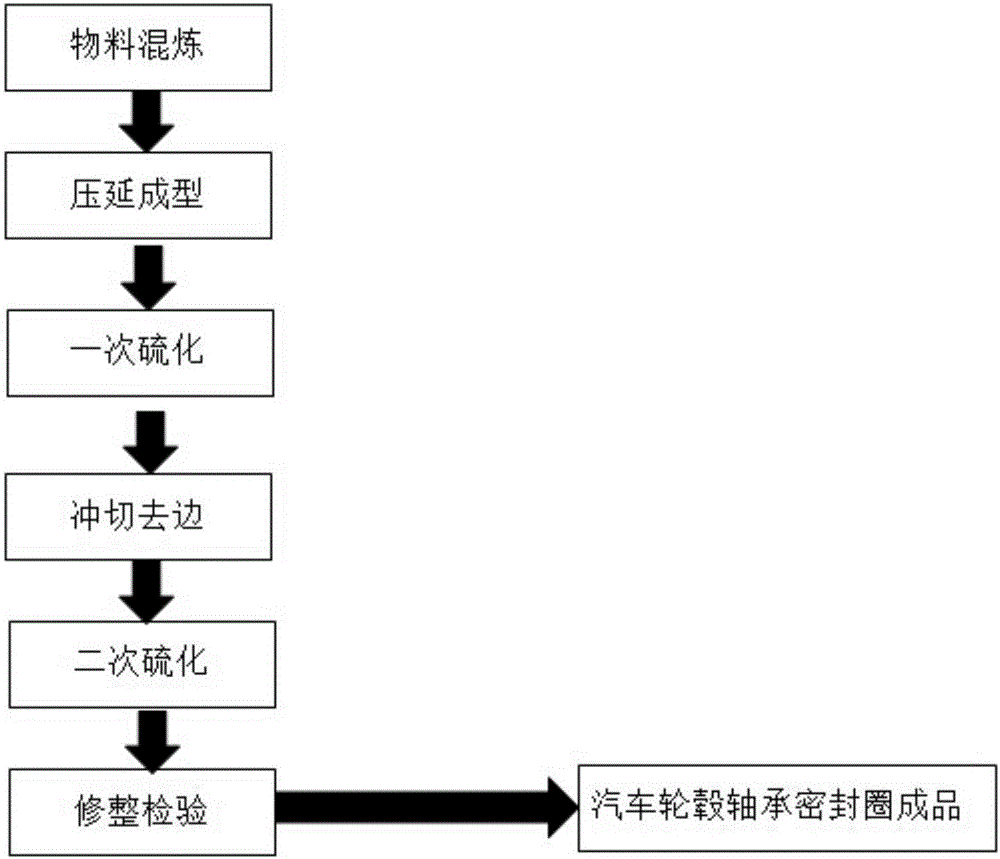

[0024] A preparation method for an automobile hub bearing sealing ring, comprising the following steps:

[0025] (1) Add 30 parts of hydrogenated nitrile rubber to the internal mixer, add 2 parts of anti-aging agent mercaptobenzimidazole, 3 parts of activator high-activity magnesium oxide, 4 parts of stearic acid, and 3 parts of imported lubricant microcrystalline wax , 0.2 parts of alumina powder, 0.3 parts of dibutyl phthalate, 3 parts of silicon dioxide, 3 parts of vulcanization accelerator di-tert-butyl peroxide, 3 parts of acid-base balance agent (PEG400), 25 parts of inorganic filler Carry out mixing for 3 minutes, add the remaining 50 parts of hydrogenated nitrile rubber, continue mixing for 15 minutes, add 15 parts of sulfur and mix for 2 minutes, then remove the glue, turn over the open mill, and then release and cool;

[0026] (2) calendering the cooled sizing material in step (1) through a calender, and forming it according to the specified weight;

[0027] (3) Pri...

Embodiment 2

[0032] A preparation method for an automobile hub bearing sealing ring, comprising the following steps:

[0033] (1) Add 25 parts of hydrogenated nitrile rubber to the internal mixer, add 3 parts of anti-aging agent mercaptobenzimidazole, 5 parts of activator high-activity magnesium oxide, 2 parts of stearic acid, and 1 part of imported microcrystalline wax as lubricant , 0.5 parts of alumina powder, 0.1 parts of dibutyl phthalate, 7 parts of silicon dioxide, 4 parts of vulcanization accelerator di-tert-butyl peroxide, 1 part of acid-base balance agent (PEG400), 30 parts of inorganic filler Carry out mixing for 5 minutes, add the remaining 50 parts of hydrogenated nitrile rubber, continue mixing for 10 minutes, add 10 parts of sulfur and mix for 2 minutes, then remove the glue, turn over the open mill, and then release and cool;

[0034] (2) calendering the cooled sizing material in step (1) through a calender, and forming it according to the specified weight;

[0035] (3) Pr...

Embodiment 3

[0040] A kind of preparation method, comprises the following steps:

[0041](1) Add 23 parts of hydrogenated nitrile rubber to the sealing ring of the automobile wheel hub bearing in the internal mixer, add 1 part of anti-aging agent mercaptobenzimidazole, 4 parts of activator highly active magnesium oxide, 3 parts of stearic acid, and imported lubricant 2 parts of microcrystalline wax, 0.1 part of alumina powder, 0.3 part of dibutyl phthalate, 5 parts of silicon dioxide, 4 parts of vulcanization accelerator di-tert-butyl peroxide, 1 part of acid-base balance agent (PEG400) 1. Mix 35 parts of inorganic fillers for 4 minutes, add the remaining 47 parts of hydrogenated nitrile rubber, continue mixing for 13 minutes, add 20 parts of sulfur and mix for 2 minutes, then remove the glue, turn over the open mill and then remove the sheet and cool;

[0042] (2) calendering the cooled sizing material in step (1) through a calender, and forming it according to the specified weight;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| activity coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com