High-temperature powdered coke dry quenching system and method

A technology for CDQ and powder coke, applied in the field of coal dry distillation, it can solve the problems of CDQ system being unable to handle powder, complicated system configuration, energy loss, etc. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

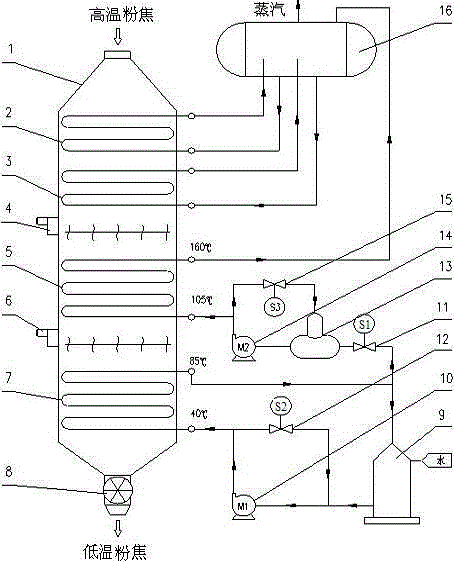

[0029] This embodiment provides a high-temperature powder coke CDQ system, which includes a heat exchanger 1, a discharge machine 8 and a water supply system. The heat exchanger 1 is a vertical heat exchanger, and is sequentially arranged from top to bottom Secondary evaporating tube 2, primary evaporating tube 3, first mixing device 4, secondary preheating tube 5, second mixing device 6 and primary preheating tube 7, the top of the heat exchanger 1 is provided with an inlet The bottom is provided with a discharge port, and the discharge port is connected with the discharge machine 8. The upper port of the secondary evaporation tube 2 and the primary evaporation tube 3 is a steam outlet, and the lower port is a water inlet. The first-stage preheating pipe 5 and the first-stage preheating pipe 7 both have water outlet from the upper end and water inlet from the lower end;

[0030] The water supply system includes a cooling tower 9, a deaerator 13, and a steam drum 16. The water...

Embodiment 2

[0034] On the basis of Embodiment 1, this embodiment provides a high-temperature powder coke CDQ system. The water outlet of the first water pump 10 is divided into two paths, and one path is connected to the water inlet of the primary preheating pipe 7 through a pipeline. The other path returns to the water inlet of the first water pump 10 through the second valve 12 and the pipeline, and the second valve 12 is a proportional regulating valve. The flow rate of the cooling water is adjusted through the second valve 12, so as to meet the requirements of 80°C discharge and water temperature at the outlet of the primary preheating pipe 7 lower than 85°C.

[0035] The water outlet of the second water pump 14 is divided into two paths, one path communicates with the water inlet of the secondary preheating pipe 5 through a pipeline, and the other path communicates with the deaerator 13 through a third valve 15 and a pipeline, and the third valve 15 is Proportional regulating valve. ...

Embodiment 3

[0039] On the basis of Example 2, this example provides a high-temperature powder coke CDQ method. For high-temperature powder semi-coke with a diameter of less than 30 mm and a temperature of 550 ° C, water is used as the heat exchange medium, and a vertical heat exchanger is used to directly Conduction heat exchange, cooling step by step to below 80°C, realize CDQ, and produce saturated steam of 0.8~1.0MPa at the same time.

[0040]The high-temperature powder coke CDQ method comprises the following steps:

[0041] Step 1) Turn on the water supply system before starting to feed semi-coke, start the first water pump 10, part of the cooling water enters the deaerator 13, and the remaining part flows back to the cooling tower 9 for recycling;

[0042] Step 2) After low-temperature dry distillation of 550°C semi-coke feed, it passes through the secondary evaporator tube 2, the primary evaporator tube 3, the secondary preheating tube 5, and the primary preheating tube 7, and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com