Preparation method of organic/inorganic composite coating

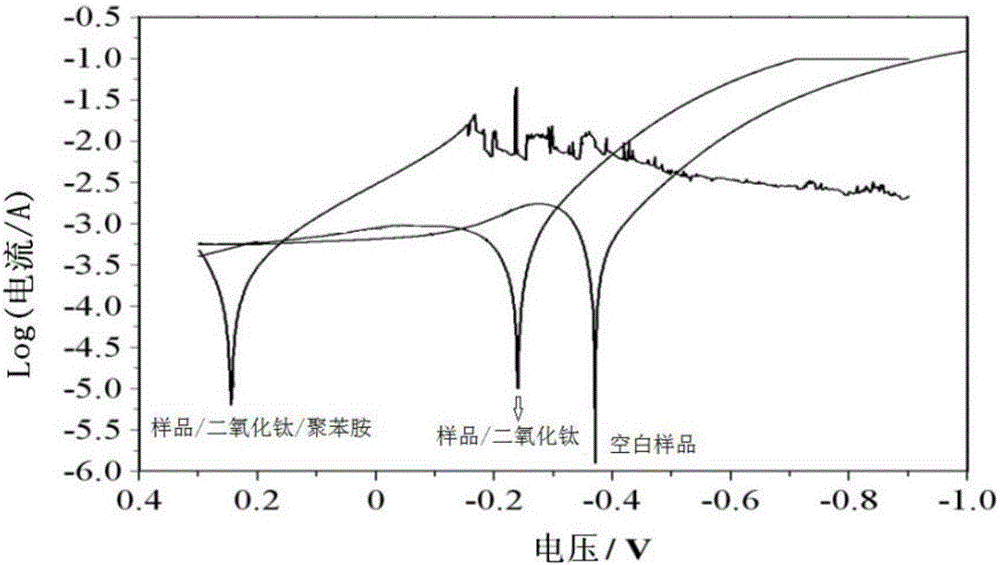

An inorganic composite and polymer coating technology, which is applied in coatings, metal material coating processes, electrolytic coatings, etc., can solve the problems of easy breakage and forming of coatings, and achieve positive corrosion potential, good stability and protection , good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

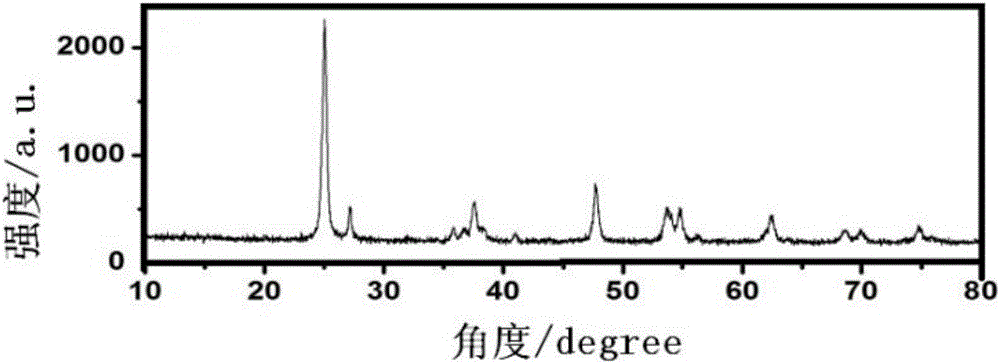

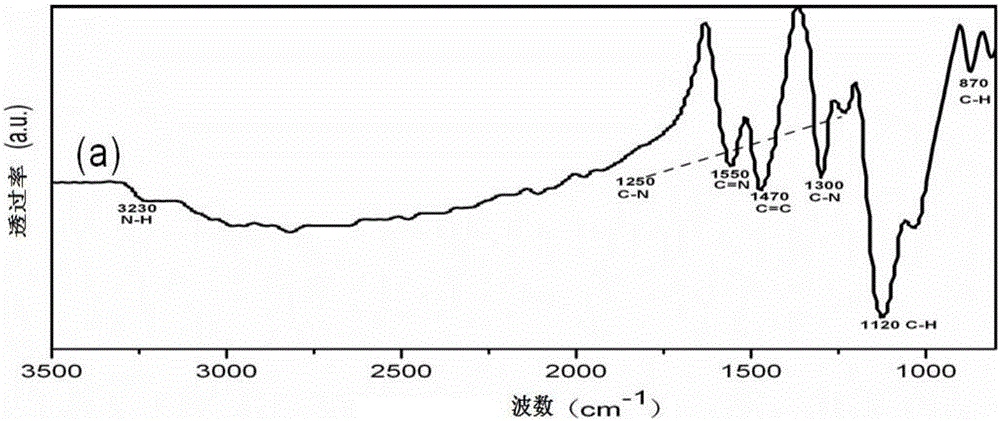

[0025] Embodiment 1. prepares nano-titanium dioxide / polyaniline composite coating

[0026] The preparation process of titanium dioxide sol was as follows: 60 mL of tetraisopropyl titanate was mixed with 1 mL of isopropanol, and slowly added dropwise to a mixture of 100 mL of acetic acid and 300 mL of deionized water, and the temperature of the mixture was kept at 0 degrees Celsius during the dropping process. The resulting mixture was reacted at 70 degrees Celsius for 8 hours under constant stirring. The obtained white sol was transferred to a polytetrafluoroethylene reactor and reacted for 24 hours under the condition of 180 degrees Celsius to obtain a nano-titanium dioxide sol.

[0027] Using 316L steel with a size of 20mm long*10mm wide*2mm thick as the base, use 3000-grit sandpaper to moderately polish the steel base, then wash it in acetone, ethanol, and deionized water for 10 minutes, and dry it. Immerse the sample into the nano-titanium dioxide sol with an immersion pu...

Embodiment 2

[0031] Embodiment 2. preparation nano zinc oxide / polypyrrole composite coating

[0032] The preparation process of zinc oxide sol is as follows: first configure a solution in which the solvent is water and ethanol, the solute is zinc acetate and polyethylene glycol 400, the total volume of the solution is 500mL, the volume ratio of water and ethanol is 1:1, and zinc acetate is in the final solution The concentration in the solution is 2mol / L, the mass fraction of polyethylene glycol 400 in the final solution is 2%, under the condition of full stirring, gradually add ammonia water to make the zinc ions first form Zn(OH) 2 The precipitate is gradually dissolved into nano-scale Zn(OH) 4 2- Sol. Stop adding ammonia water when the pH of the sol measured by pH test paper is 10-11, and the sol preparation is completed.

[0033] Using 316L steel with a size of 20mm long * 10mm wide * 2mm thick as the base, use 3000-grit sandpaper to moderately polish the steel sheet, then wash in a...

Embodiment 3

[0036] Embodiment 3. preparation nano-titanium dioxide / polypyrrole composite coating

[0037] The preparation process of titanium dioxide sol is as follows: 30mL of tetraisopropyl titanate is mixed with 1mL of isopropanol, slowly added dropwise to the mixed solution of 80mL acetic acid and 240mL deionized water, and the temperature of the mixed solution of acetic acid and deionized water is maintained during the dropping process is 0 degrees Celsius. The resulting mixture was reacted at 90 degrees Celsius for 8 hours under constant stirring. The obtained white sol was transferred to a polytetrafluoroethylene reactor and reacted for 24 hours under the condition of 230 degrees Celsius to obtain a nano-titanium dioxide sol.

[0038] Using 316L steel with a size of 20mm long*10mm wide*2mm thick as the base, use 3000-grit sandpaper to moderately polish the steel base, then wash it in acetone, ethanol, and deionized water for 10 minutes, and dry it. Immerse the sample into the nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com