Electric arc furnace steelmaking process with oxygen, fuel and powder common injection

An electric arc furnace and powder technology, which is applied in the field of technology, can solve the problems of reducing slag-forming agents, etc., and achieve the effects of reduced consumption, reduced power consumption, and accelerated smelting rhythm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described in detail below; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

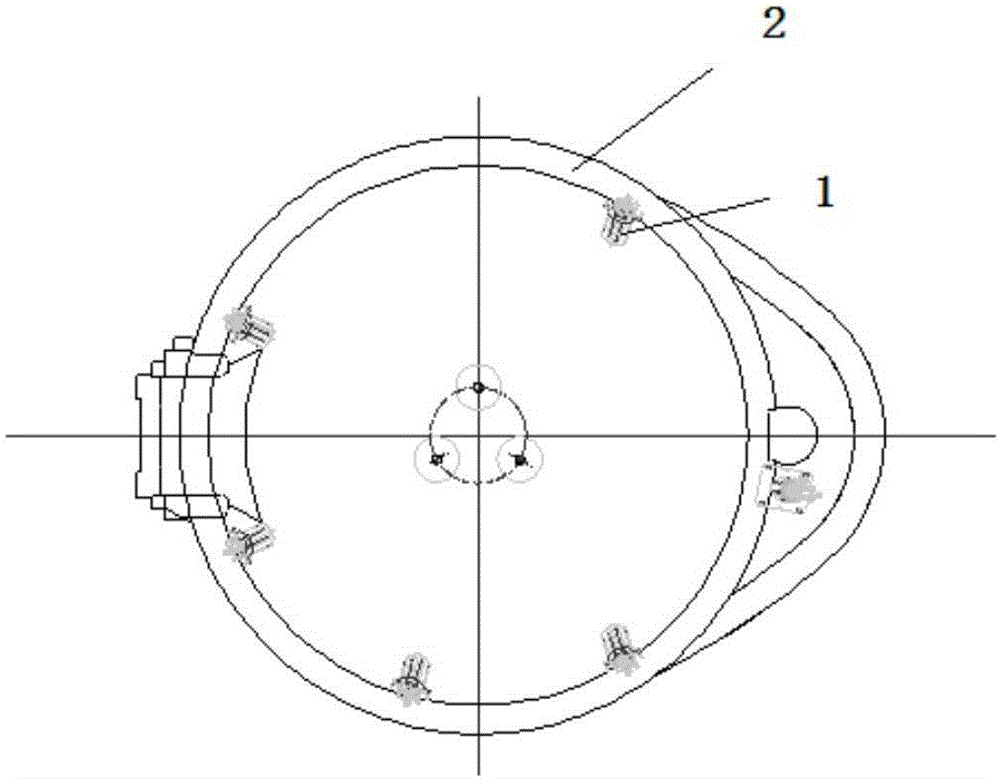

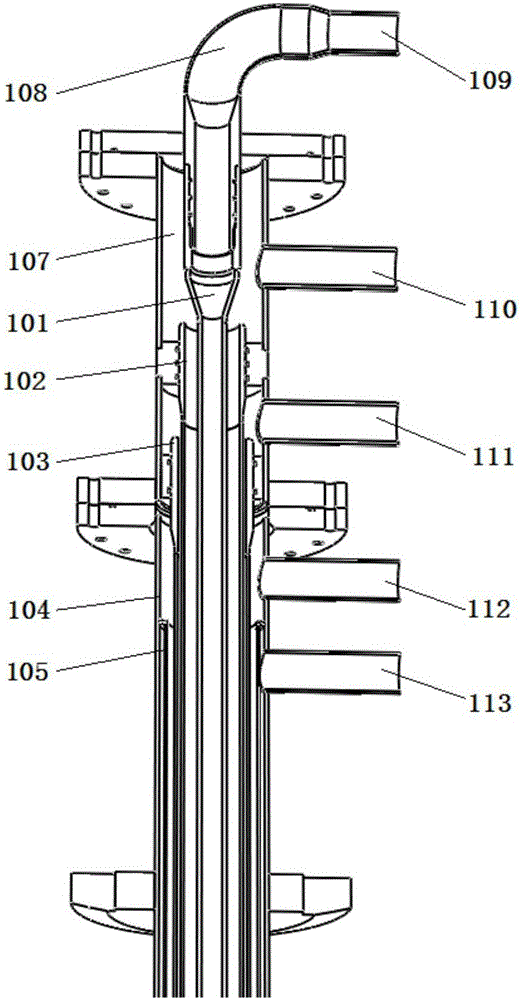

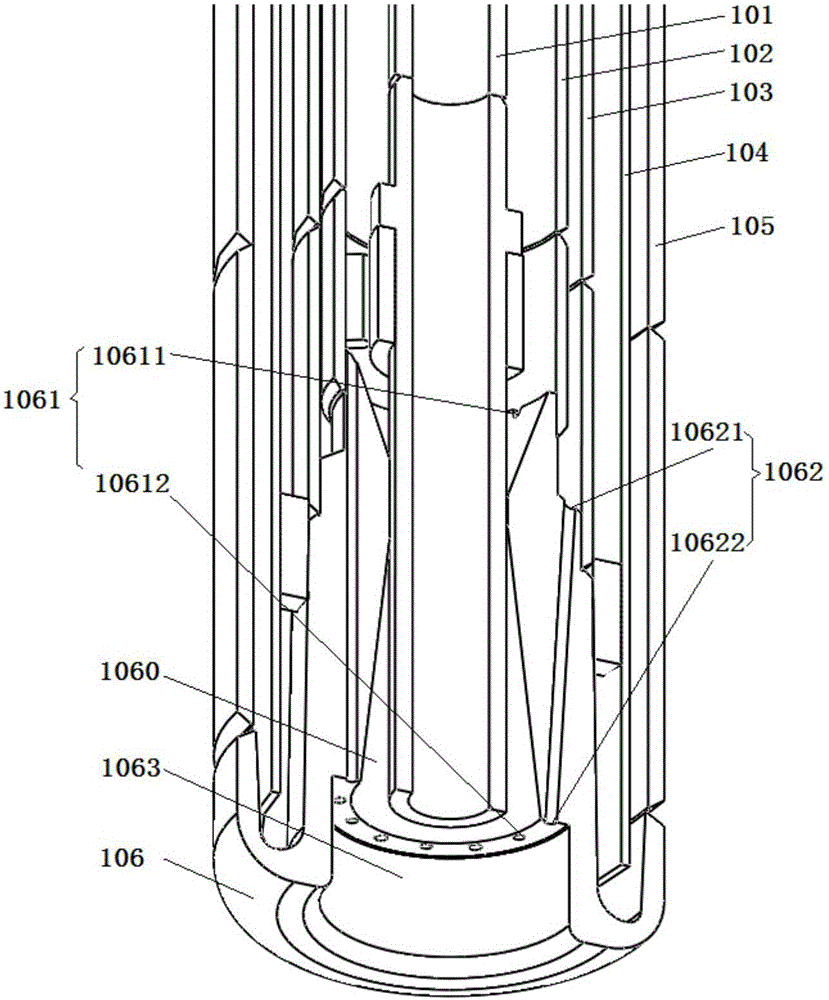

[0030] Such as figure 1 As shown, the present invention provides an electric arc furnace steelmaking process of co-injection of oxygen, fuel, and powder. The oxygen, fuel, and powder input devices are combined into different injection furnaces according to the capacity of the electric arc furnace 2 and the structure of the metal material in the furnace. The input module is installed on the furnace wall, and the injection of oxygen, fuel, and powder is completed by the same injection input module with water cooling, and the injection flow rate of oxygen, fuel, and powder are determined according to the needs of the steelmaking process. Injection type and speed, the injection input module with water-cooled cooling is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com