Caseless cartridge

A technology for caseless bullets and bullets, which is applied in warheads, ammunition, weapon accessories, etc. It can solve problems such as increased chamber temperature, cold system research, and inability to dissipate heat in time, so as to speed up combustion, increase shooting distance, and solve spontaneous combustion. problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

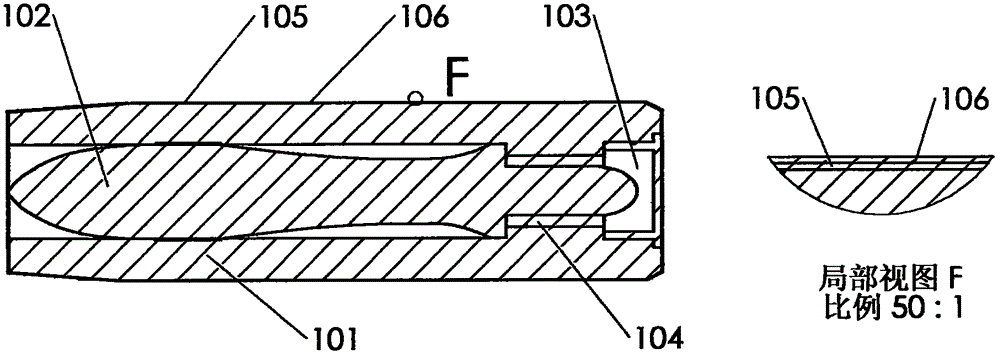

[0025] like figure 1 As shown, the caseless bullet of this embodiment is composed of a propellant column 101 , a warhead 102 , a primer 103 , a fast-burning charge 104 , a moisture-proof plastic film 105 , and an isolation and heat dissipation aluminum foil 106 . The propellant powder column 101 is bonded with the propellant powder by a combustible adhesive, and then molded into a solid propellant powder column. Its shape is a right cylinder or other shapes according to the needs of the adapted gun. The rear section through the hole and near the primer has a step to allow the entire bullet to be buried in the hole. like figure 2 As shown, the warhead 102 is composed of a nose cone 1021, an elastic band 1022, a tail protrusion 1023, a rear elastic band 1024, a tail post 1025 and other parts. The function of the nose cone 1021 is well known and will not be discussed here. The bullet band 1022 is the main contact surface between the bullet and the gun barrel. Its first functio...

no. 2 approach

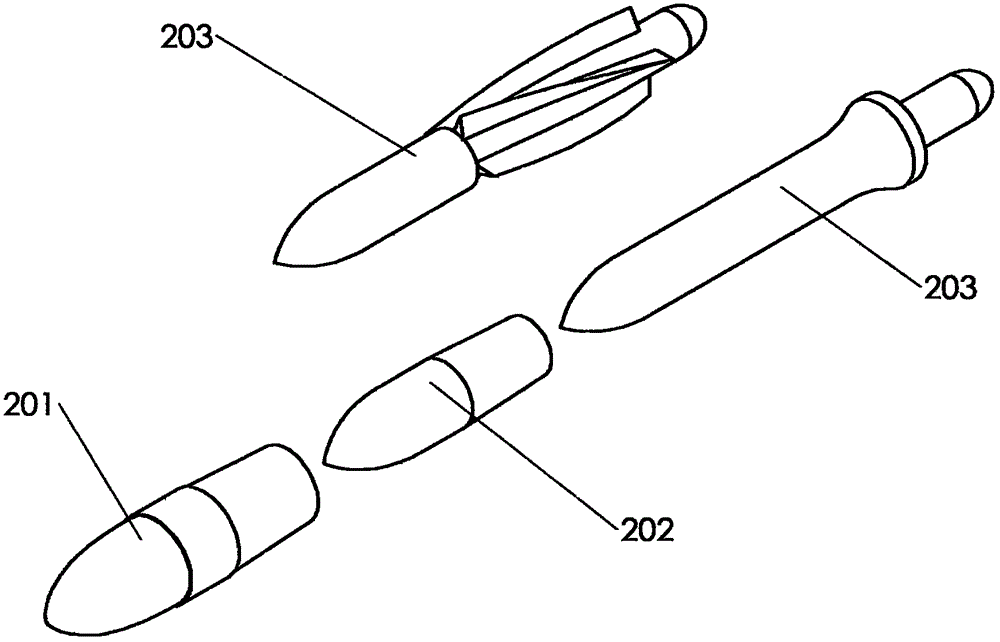

[0027] like image 3 As shown, the bullet of the caseless bullet of the present embodiment is assembled, and is made up of bullet jacket 201, lead filling 202, and bullet core 203. Tail protrusion, rear bullet belt and tail post are on bullet core 203. When the warhead has a spiral wing, the spiral wing and the tail post are on the bullet core 203.

no. 3 approach

[0029] This embodiment is an embodiment of a warhead with a helical wing, see Figure 4 , consists of a propellant charge column 301, a warhead 302, a primer 303, a fast-burning charge 304, a moisture-proof plastic film 305, an isolated heat-dissipating copper foil 306, and an interwing charge 307. The propellant column 301 also uses a combustible adhesive to first bond the propellant powder, and then molds it into a solid propellant column. There is a through hole in the center of the column to accommodate the entire warhead. There is a boss on the rear side of the position, which acts on the rear side of the belt to prevent the warhead from moving in the direction of the primer. like Figure 5As shown, the warhead 302 is composed of a nose cone 3021, an elastic belt 3022, a spiral wing 3023, and a tail post 3024. The functions of the nose cone 3021 and the elastic belt 3022 are the same as those in the first embodiment. The helical wing 3023 is a sheet-shaped body that ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com