Diamond-like carbon film on surface of easy-to-rust metal piece and preparation method of diamond-like carbon film

A technology of diamond film and metal parts, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of coating defects, difficult to grow dense DLC coating on metal wire drawing/sandblasting surface, etc., to achieve The effect of uniform thickness, improved diffraction, and improved ionization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

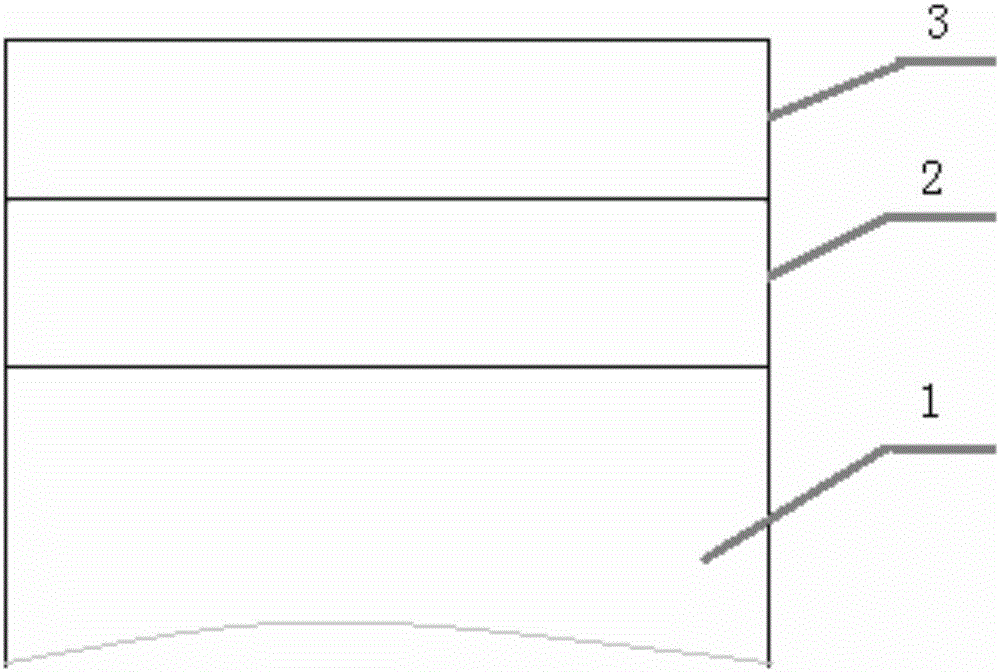

[0032] Embodiment 1: the surface treatment of 17-4H metal test piece

[0033] After the 17-4H steel test piece with the three-dimensional dimensions of length, width and thickness of 100mmx30mmx2mm is polished, half of the polished surface is brushed, and then the surface is treated in the following order.

[0034]1) After the 17-4H steel test piece is cleaned in the cleaning line, it is dried with oil-free compressed air, hung on the fixture, and put into the hauzer flexicoat 850 vacuum coating device; the magnetron sputtering target is a pair of intermediate frequency Cr twins target. The cleaning line adopts multi-step multi-tank equipment cleaning, including degreasing-rinsing-ultrasonic cleaning-rinsing-acidic solution cleaning-alkaline solution neutralization-rinsing-deionized water rinsing-preservative rinsing and other cleaning steps.

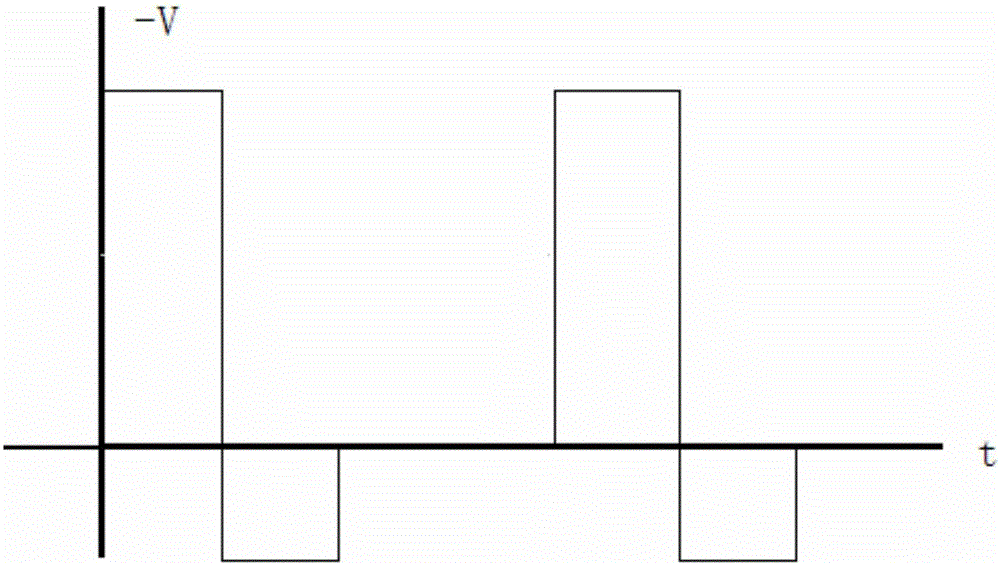

[0035] 2) Close the door of the vacuum chamber, and start the workpiece holder to rotate; the vacuum chamber is pumped to a vacuum lo...

Embodiment 2

[0040] Embodiment 2: the surface treatment of 45A steel test piece

[0041] After the 45A steel test piece with the three-dimensional dimensions of length, width and thickness of 100mmx30mmx2mm is polished, half of the polished surface is sandblasted, and then the surface is treated in the following order.

[0042] 1) After the test piece is cleaned in a special cleaning line, it is dried with oil-free compressed air, mounted on a fixture, and placed in a hauzer flexicoat 850 vacuum coating device; the magnetron sputtering target is a pair of intermediate frequency Ti twin targets. The cleaning line adopts multi-step multi-tank equipment cleaning, including degreasing-rinsing-ultrasonic cleaning-rinsing-acidic solution cleaning-alkaline solution neutralization-rinsing-deionized water rinsing-preservative rinsing and other cleaning steps.

[0043] 2) Fix the pretreated workpiece on the workpiece rack, close the door of the vacuum chamber, and start the workpiece rack to rotate;...

Embodiment 3H13

[0048] The surface treatment of embodiment 3H13 die steel test piece

[0049] After the H13 steel test piece with the three-dimensional dimensions of length, width and thickness of 100mmx30mmx2mm is polished, half of the polished surface is sandblasted, and then the surface is treated in the following order.

[0050] 1) After the test piece is cleaned in a special cleaning line, it is dried with oil-free compressed air, mounted on a fixture, and placed in a hauzer flexicoat 850 vacuum coating device; the magnetron sputtering target is a pair of intermediate frequency Cr twin targets. The cleaning line adopts multi-step multi-tank equipment cleaning, including degreasing-rinsing-ultrasonic cleaning-rinsing-acidic solution cleaning-alkaline solution neutralization-rinsing-deionized water rinsing-preservative rinsing and other cleaning steps.

[0051] 2) Fix the pretreated workpiece on the workpiece rack, close the door of the vacuum chamber, and start the workpiece rack to rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com