Preparation method of ferritic ductile iron

A technology of nodular cast iron and ferrite, which is applied in the field of preparation of ferritic nodular cast iron to achieve good inoculation effect, excellent toughness and impact plasticity, and the effect of increasing the number of graphite nodules and ferrite content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

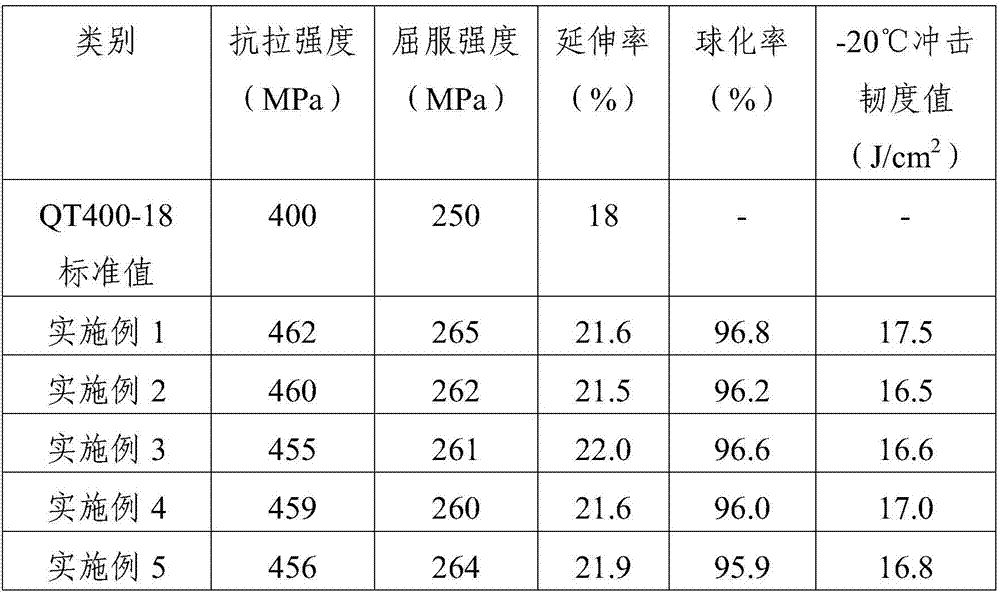

Examples

Embodiment 1

[0019] A ferritic spheroidal graphite cast iron, wherein the mass percentage of each element component in the ferritic spheroidal graphite cast iron is: carbon 3.6%, silicon 2.5%, manganese 0.32%, cerium 0.035%, magnesium 0.05%, yttrium 0.09%, molybdenum 0.015 %, Rhenium 0.025%, Phosphorus≤0.04%, Sulfur≤0.018%, the balance is iron.

[0020] The preparation method of ferritic nodular cast iron specifically includes the following steps:

[0021] (1) Melt low-phosphorus, low-sulfur, high-quality pig iron and scrap with an intermediate frequency induction furnace at 1450°C. After all melting, detect the content of each element in the molten iron, and adjust the content of each element to meet the requirements of the formula, and then perform desulfurization treatment ;

[0022] (2) Mix 0.45% of the total weight of the molten iron with silicon carbide powder and 1.3% of the total weight of the molten iron with a rare earth magnesium alloy (with a particle size of 1.5mm), then pour it int...

Embodiment 2

[0027] A ferritic spheroidal graphite cast iron, wherein the mass percentage of each element component in the ferritic spheroidal graphite cast iron is: carbon 3.8%, silicon 2.4%, manganese 0.35%, cerium 0.03%, magnesium 0.045%, yttrium 0.08%, and molybdenum 0.02% %, rhenium 0.02%, phosphorus ≤0.04%, sulfur ≤0.018%, and the balance is iron.

[0028] The preparation method of ferritic nodular cast iron specifically includes the following steps:

[0029] (1) Melt low-phosphorus and low-sulfur high-quality pig iron and scrap with an intermediate frequency induction furnace at 1480℃. After all melting, the content of each element in the molten iron is detected, and the content of each element is adjusted to meet the requirements of the formula, and then desulfurization treatment ;

[0030] (2) Mix 0.35% of the total weight of the molten iron with silicon carbide powder and 1.5% of the total weight of the molten iron with rare earth magnesium alloy (with a particle size of 0.5mm), then p...

Embodiment 3

[0035] A ferritic spheroidal graphite cast iron, wherein the mass percentages of the elements in the ferritic spheroidal graphite cast iron are: carbon 3.5%, silicon 2.7%, manganese 0.29%, cerium 0.04%, magnesium 0.045%, yttrium 0.1%, molybdenum 0.01% %, rhenium 0.03%, phosphorus ≤ 0.04%, sulfur ≤ 0.018%, and the balance is iron.

[0036] The preparation method of ferritic nodular cast iron specifically includes the following steps:

[0037] (1) Melt low-phosphorus and low-sulfur high-quality pig iron and scrap with an intermediate frequency induction furnace at 1460℃. After all melting, the content of each element in the molten iron is detected, and the content of each element is adjusted to meet the requirements of the formula, and then desulfurization treatment ;

[0038] (2) Mix 0.4% of the total weight of the molten iron with silicon carbide powder and 1.4% of the total weight of the molten iron with a rare earth magnesium alloy (with a particle size of 1mm), then pour it into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com