Method for manufacturing desulfurization and denitrification activated carbon from waste activated carbon

A desulfurization and denitrification, activated carbon technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low combustion calorific value, low recovery efficiency of recovery process, etc., and achieve the goal of improving economic benefits, saving energy and time Unified effect of consumption, environmental benefit and social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

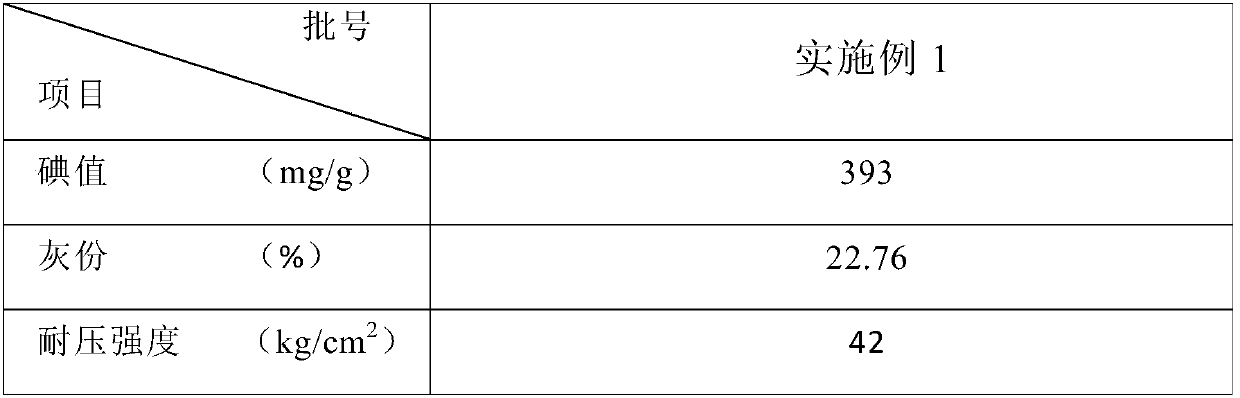

Embodiment 1

[0075] The desulfurization and denitrification activated carbon in the present embodiment is made of powdery waste activated carbon, tar and water, and its weight percentage is:

[0076] Powdered waste activated carbon 70%; tar 23%; potassium hydroxide or magnesium oxide 2%; water 5%. The tar here adopts high-temperature coal tar.

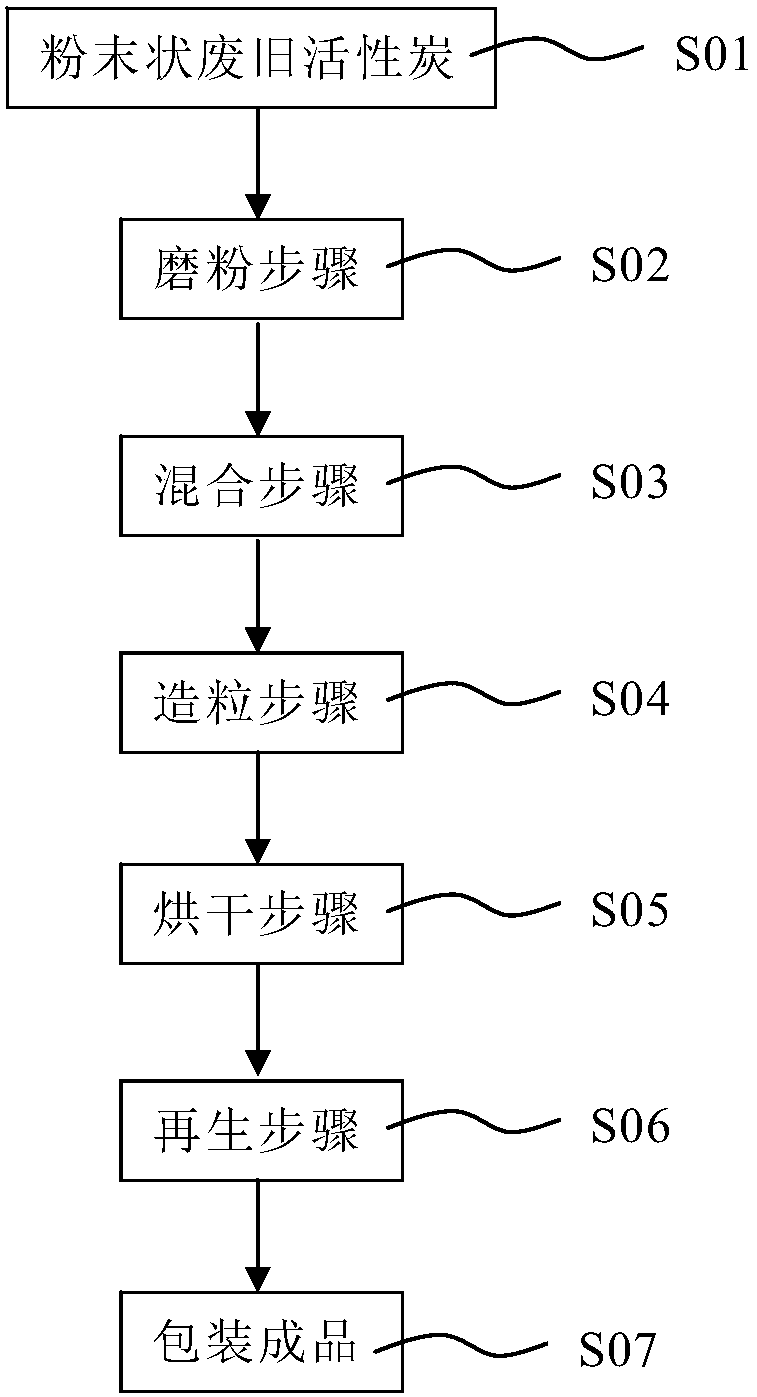

[0077] The preparation method of above-mentioned gac is: it comprises the following steps:

[0078] 1), preparation of raw materials: grinding into 200 mesh powdered waste activated carbon;

[0079] 2), preparation of tar: first adjust the temperature of the tar to 55°C, then stir evenly, then prepare the tar into a mixed tar with a bitumen content of 50% and keep its temperature at 55°C;

[0080] 3), making charcoal paste: add the prepared powdery waste activated carbon, prepared tar, potassium hydroxide or magnesium oxide and water into the mixer according to the above weight percentage and stir evenly to make charcoal paste;

[0081] 4) Formi...

Embodiment 2

[0085] The desulfurization and denitrification activated carbon in the present embodiment is made of powdery waste activated carbon, tar and water, and its weight percentage is:

[0086] Powdered waste activated carbon 75%; tar 15%; water 8%; potassium hydroxide or magnesium oxide 2%. Coal tar adopts high temperature coal tar.

[0087] The preparation method of above-mentioned gac is: it comprises the following steps:

[0088] 1), preparation of raw materials: grinding into 240 mesh powdered waste activated carbon;

[0089] 2), preparation of tar: first adjust the temperature of the tar to 50°C, then stir evenly, then prepare the tar into a mixed tar with a bitumen content of 60% and keep its temperature at 50°C;

[0090] 3), making charcoal paste: add the prepared powdery waste activated carbon, prepared tar, potassium hydroxide or magnesium oxide and water into the mixer according to the above weight percentage and stir evenly to make charcoal paste;

[0091] 4) Forming a...

Embodiment 3

[0095] The desulfurization and denitrification activated carbon in the present embodiment is made of powdery waste activated carbon, tar and water, and its weight percentage is:

[0096] 5% bituminous coal, 68% waste activated carbon, 5% asphalt, 8% coking coal, 2% potassium hydroxide or magnesium oxide and 12% tar.

[0097]Coking coal from Qinyuan, Xiangyuan and other places is used, and the caking index is required to be 75-95; bituminous coal is Jurassic long-flame coal, high-temperature coal tar, and coal-modified asphalt.

[0098] The preparation method of above-mentioned gac is: it comprises the following steps:

[0099] 1), preparation of raw materials: firstly crush bituminous coal and coking coal into coal lumps smaller than 12mm respectively, then mix bituminous coal and coking coal according to the above weight percentage, and then grind together with powdery waste activated carbon into 220-mesh powder;

[0100] 2), preparation of tar: first adjust the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| abrasion resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com