Surface treatment method of damage below machining face of carbon-fiber-reinforced composite material

A technology of reinforced composite materials and surface treatment, which is applied in the fields of analyzing materials, using wave/particle radiation for material analysis, and using measurement of secondary emissions for material analysis, etc. It can solve the problems of damage expansion and failure under the surface, and achieve a clean surface The effect of complete, simple and easy-to-operate surface treatment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation of the embodiments of the present invention will be described in detail below in conjunction with the technical solutions and drawings.

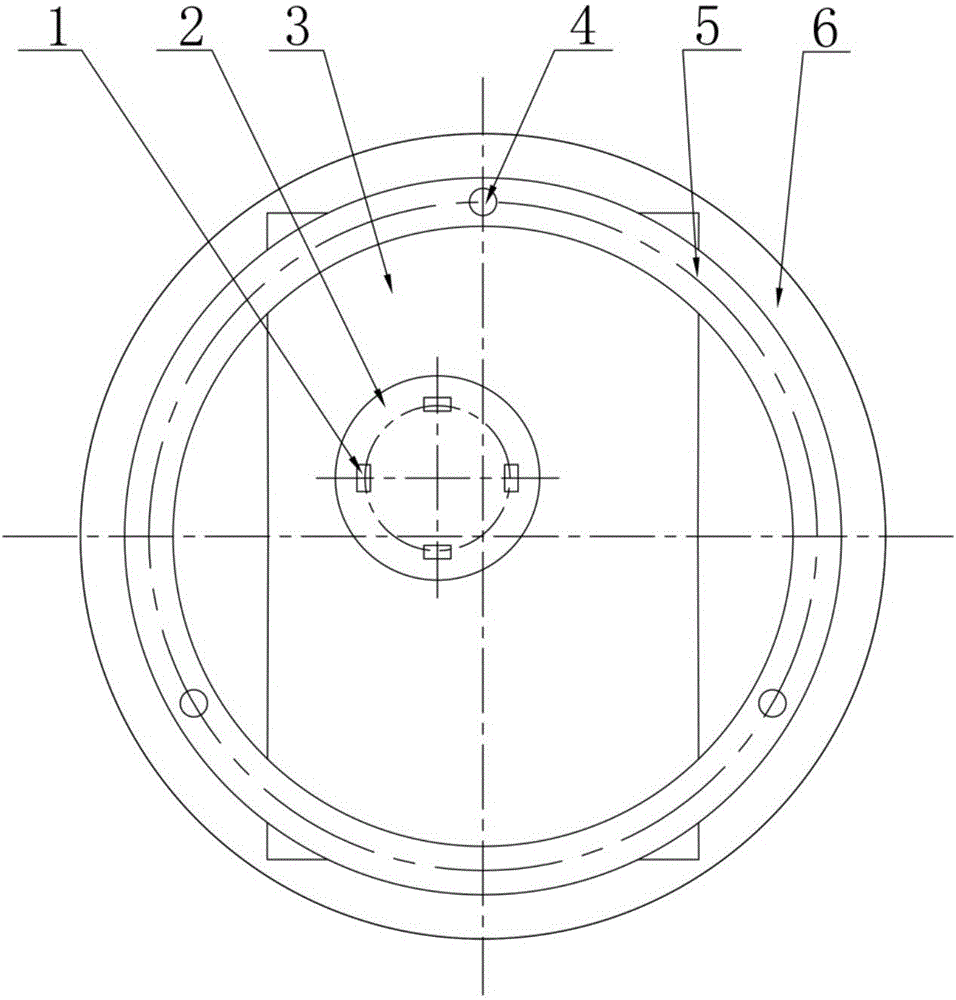

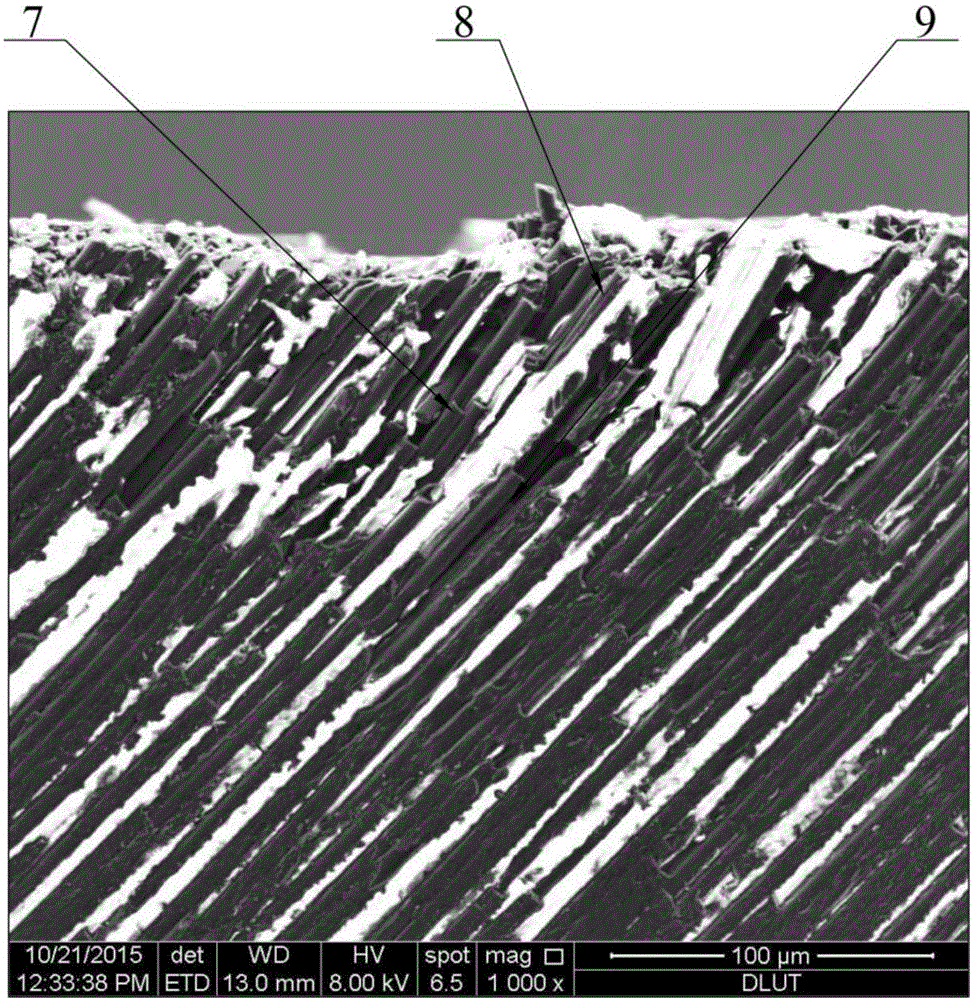

[0015] attached figure 1 It is a schematic diagram of the grinding mechanism of the present invention, a surface treatment method for under-surface damage observation of carbon fiber reinforced composite materials, including the steps of sampling, grinding, cleaning, drying, and observation. Taking the processed unidirectional carbon fiber reinforced composite laminate as an example, the specific steps are as follows:

[0016] The first step: Sampling is to use a sawing machine to cut a processed carbon fiber reinforced composite material sample 1 with a size of about 20mm×20mm, and be careful not to damage the processed surface when sawing. At the same time, use sandpaper to clean the burrs on the edge of the sample 1. If there are protrusions on the edge of the sample 1 during processing, also use sandpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com