Preparation device and method for flaky powder

A flake powder and preparation device technology, which is applied in the field of flake powder preparation devices, can solve problems such as difficult preparation of alloy and compound powder, difficulty in large-scale preparation, complex procedures, etc., and achieve simple structure, no pollution in operation, and low energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

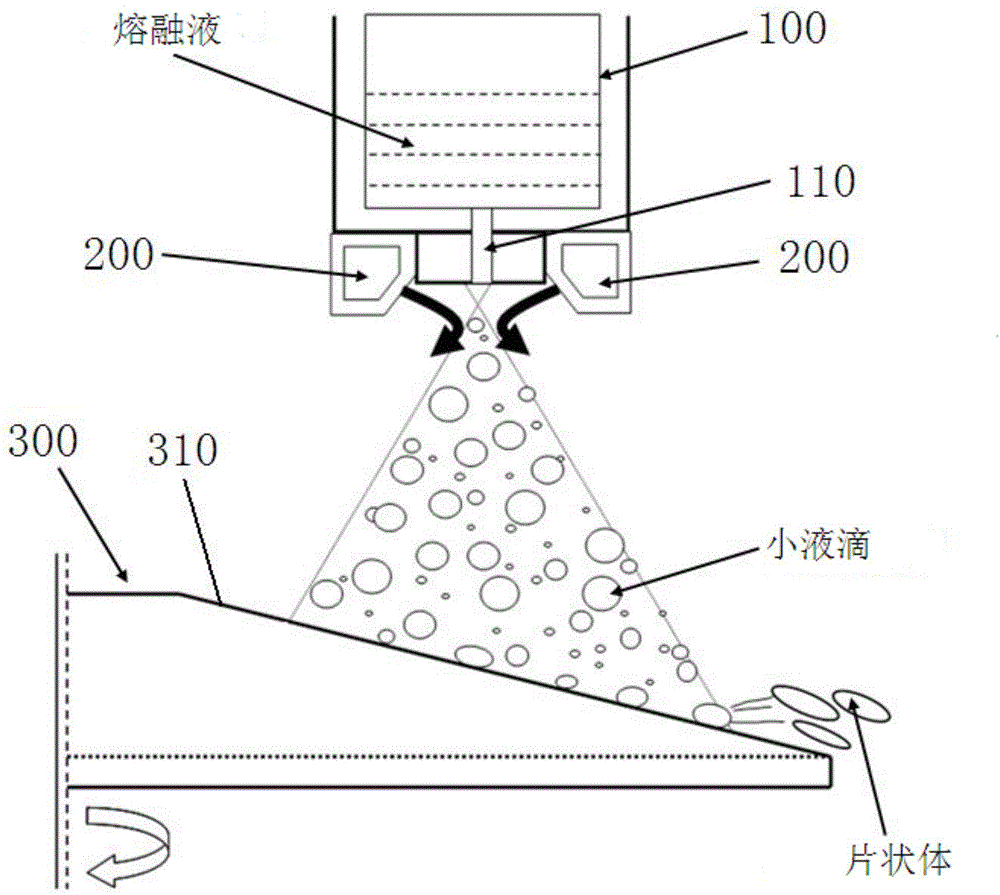

[0051] The preparation device of the present invention has high cooling efficiency, so the preparation device of the present invention can be used to prepare flake metal or alloy powder, flake amorphous, quasicrystal and microcrystalline powder. Through the adjustment of parameters such as gas injection pressure and rotating disk speed, flake metal powder with a thickness of 1-3 μm, an aspect ratio of 50-300, and uniform particle size distribution can be prepared.

[0052] Correspondingly, the present invention also provides a preparation method of flake powder, the preparation method uses the above-mentioned preparation device, which includes the following steps:

[0053] S100: melting the raw material in the melting device 100 to obtain a molten liquid;

[0054] S200: The molten liquid is sprayed out through the nozzle 110 under the action of pressure and then falls under the action of gravity, and interacts with the atomizing gas of the gas atomization device 200 during the...

Embodiment 1

[0062] Flake metal powder of Fe-Si-Al was prepared.

[0063] The preparation steps are as follows:

[0064] S100: melting the Fe-Si-Al alloy raw material in a melting device to obtain a molten liquid; wherein the heating temperature in the melting and holding furnace is 150°C for superheating the melt, melting in a nitrogen protective atmosphere, and the diameter of the nozzle of the crucible is 2mm;

[0065] S200: After the molten liquid is ejected from the nozzle, it interacts with the atomized gas of the gas atomization device and breaks into small droplets, where the gas atomization pressure is 2MPa;

[0066] S300: The small droplets fall onto the turntable to form flakes; the distance between the turntable and the nozzle is 100mm, and the rotation speed of the turntable is 10000 rpm;

[0067] S400: Perform subsequent processing on the flakes. The cooling water pressure is 2MPa.

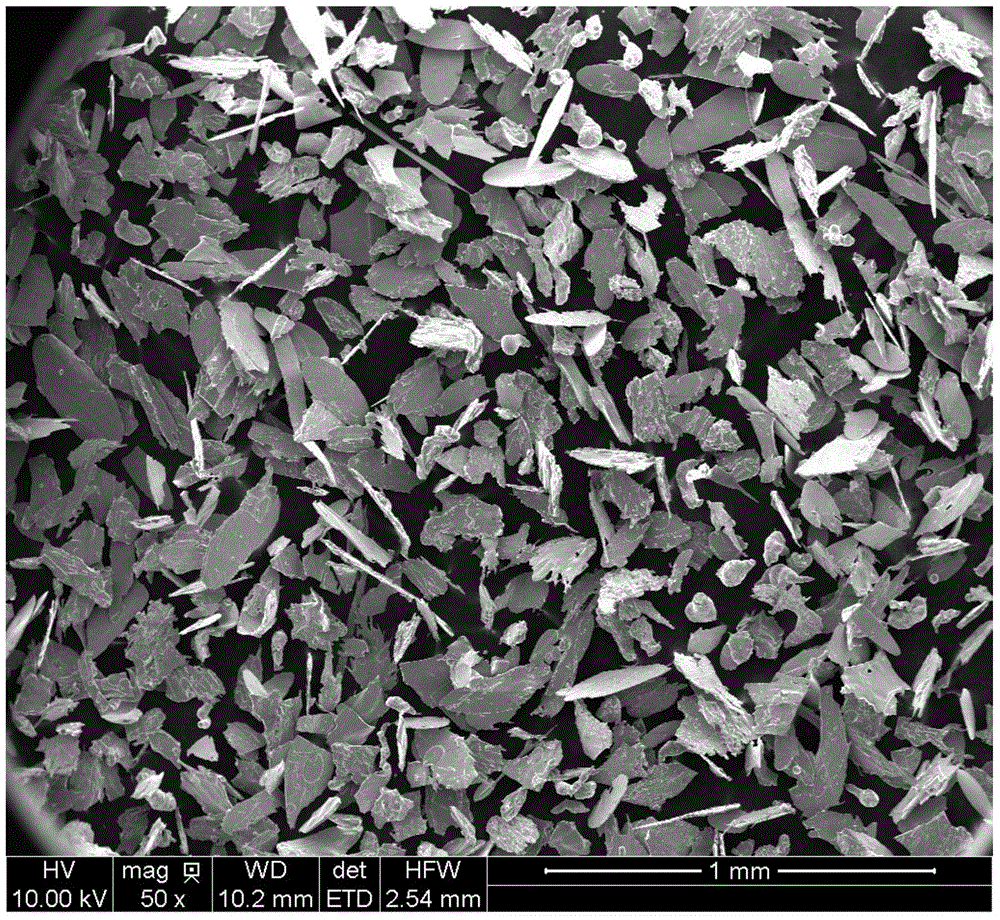

[0068] The SEM topography of the Fe-Si-Al flake metal powder that embodiment one makes is ...

Embodiment 2

[0070] Prepare flake aluminum powder. The preparation steps are the same as in Example 1.

[0071] The rotary disk in this embodiment is wedge-shaped.

[0072] The main process parameters are: the heating temperature in the melting furnace is 200°C for the superheating of the melt, the melting process is protected by argon, the gas atomization pressure is 2.5MPa, the diameter of the melt nozzle is 1.5mm, and the distance between the central axis of the nozzle and the wedge-shaped rotary disk The spacing is 80mm, the rotation speed of the wedge-shaped rotary disc is 12000 rpm, and the cooling water pressure is 2MPa.

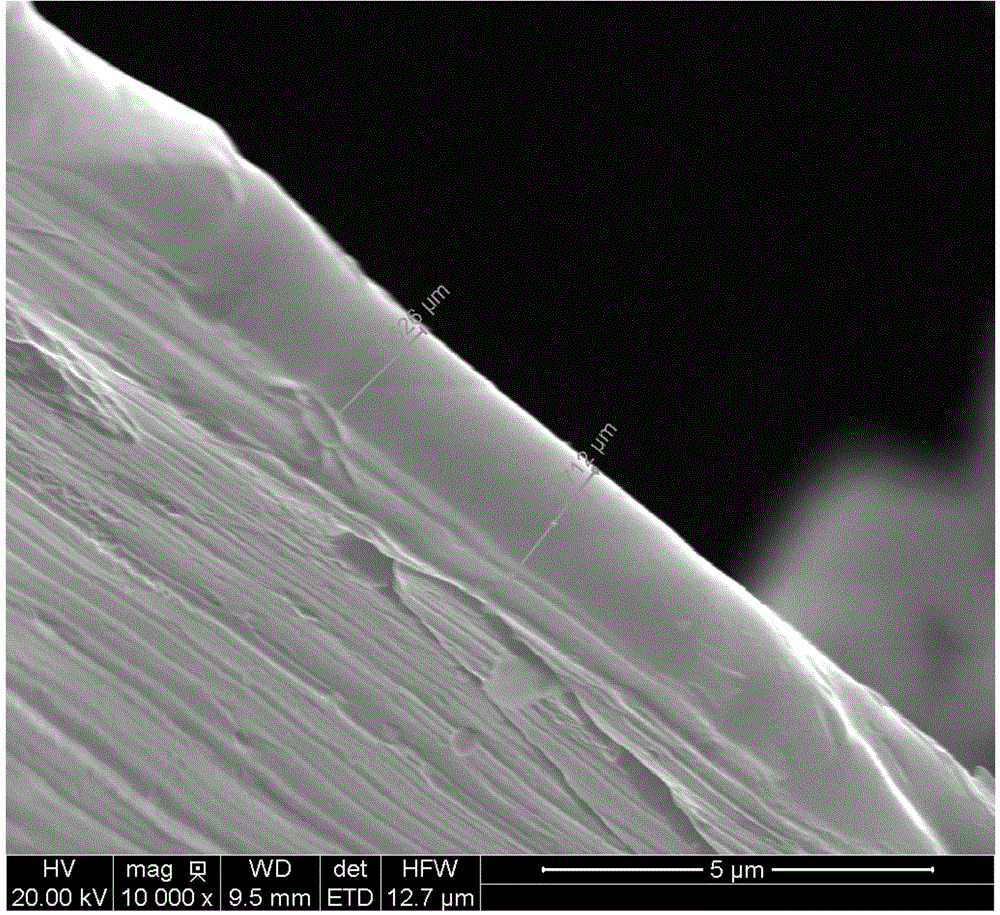

[0073] The SEM image of the flake aluminum powder prepared according to the above parameters shows that the thickness of the powder is about 1.2 μm, the average particle size is about 150 μm, the aspect ratio is between 100 and 300, the surface is bright and defect-free, and the powder particle size Centralized distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com