Biodegradable nanometer filling function master batch and preparation method and application thereof

A nano-filling and functional masterbatch technology, which is applied in the field of biodegradable plastic masterbatch manufacturing, can solve the problem of surface treatment effect of inorganic materials, improper control of particle size and particle size distribution width, and its physical properties cannot meet the requirements of product use. Improve the processing performance and processing environment, improve the mechanical properties, and increase the compatibility of biodegradable materials and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

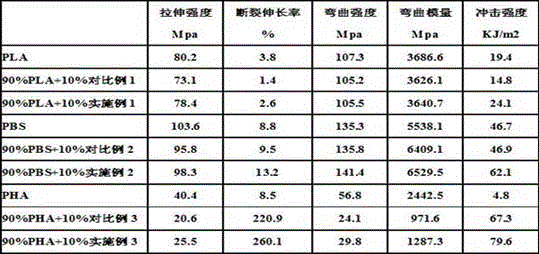

Examples

Embodiment 1

[0035] (1) Dry PLA in a blast oven at 70°C for 24 hours, and dry barium sulfate nanoparticles (particle size D50=50nm) in a blast oven at 110°C for 12 hours;

[0036] (2) Take 20 parts of PLA, 78 parts of nano barium sulfate, 0.3 parts of paraffin wax, 0.5 parts of polyethylene wax, 0.5 parts of stearic acid, 0.3 parts of zinc stearate, 0.3 parts of titanate coupling agent, four [β-( 0.1 part of 3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester was mixed in an internal mixer for 15-20 minutes;

[0037] (3) Pour the raw materials after mixing and plasticizing into a single-screw extruder while they are hot, and extrude, and cut the die surface eagerly to obtain a biodegradable nano-filled functional masterbatch. The temperature zones of the single-screw extruder are set to 140°C in the first zone, 145°C in the second zone, 150°C in the third zone, 155°C in the fourth zone, and 160°C in the fifth zone. L / D is 8:1;

[0038] (4) Blend the prepared masterbatch ...

Embodiment 2

[0045] (1) Dry PBS in a blast oven at 80°C for 24 hours, and dry nano-calcium carbonate (particle size D50=30nm) in a blast oven at 110°C for 12 hours;

[0046] (2) Take 25 parts of PBS, 71 parts of nano calcium carbonate, 0.8 parts of paraffin wax, 1.2 parts of polyethylene wax, 0.8 parts of stearic acid, 0.6 parts of zinc stearate, 0.5 parts of aluminate coupling agent, four [β-( 0.1 part of 3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, banburying in an internal mixer for 15~20min;

[0047] (3) Pour the raw materials after mixing and plasticizing into a single-screw extruder while they are hot, and extrude, and cut the die surface eagerly to obtain a biodegradable nano-filled functional masterbatch. Each temperature zone of the single-screw extruder is set to 160°C in the first zone, 165°C in the second zone, 170°C in the third zone, 175°C in the fourth zone, and 180°C in the fifth zone. L / D is 8:1;

[0048] (4) Blend the prepared masterbatch with P...

Embodiment 3

[0055] (1) Dry PHA in a blast oven at 60°C for 24 hours, and dry nano-talc powder (particle size D50=80nm) in a blast oven at 110°C for 12 hours;

[0056] (2) Take 25 parts of PHA, 70 parts of nano-talc powder, 0.8 parts of white oil, 1.6 parts of polyethylene wax, 1.0 parts of stearic acid, 0.8 parts of zinc stearate, 0.7 parts of aluminate coupling agent, 2,6- 0.1 part of di-tert-butyl-4-methylphenol, banburying in an internal mixer for 15~20min;

[0057] (3) Pour the raw materials after mixing and plasticizing into a single-screw extruder while they are hot, and extrude, and cut the die surface eagerly to obtain a biodegradable nano-filled functional masterbatch. The temperature zones of the single-screw extruder are set to the first zone 130°C, the second zone 135°C, the third zone 140°C, the fourth zone 145°C, and the fifth zone 150°C, the screw speed is 30~50rpm, and the screw length-to-diameter ratio L / D is 8:1;

[0058] (4) Blend the prepared masterbatch with PHA, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com