Nodular cast iron subsoiling shovel tip of agricultural machine and production technique of nodular cast iron subsoiling shovel tip

A technology of agricultural machinery and manufacturing process, which is applied in the field of nodular cast iron sub-loosening shovel tip for agricultural machinery and its manufacturing process, which can solve the problems of increased production cost and high abnormal damage rate, improve production efficiency, solve the problem of easy breakage, low cost, etc. price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

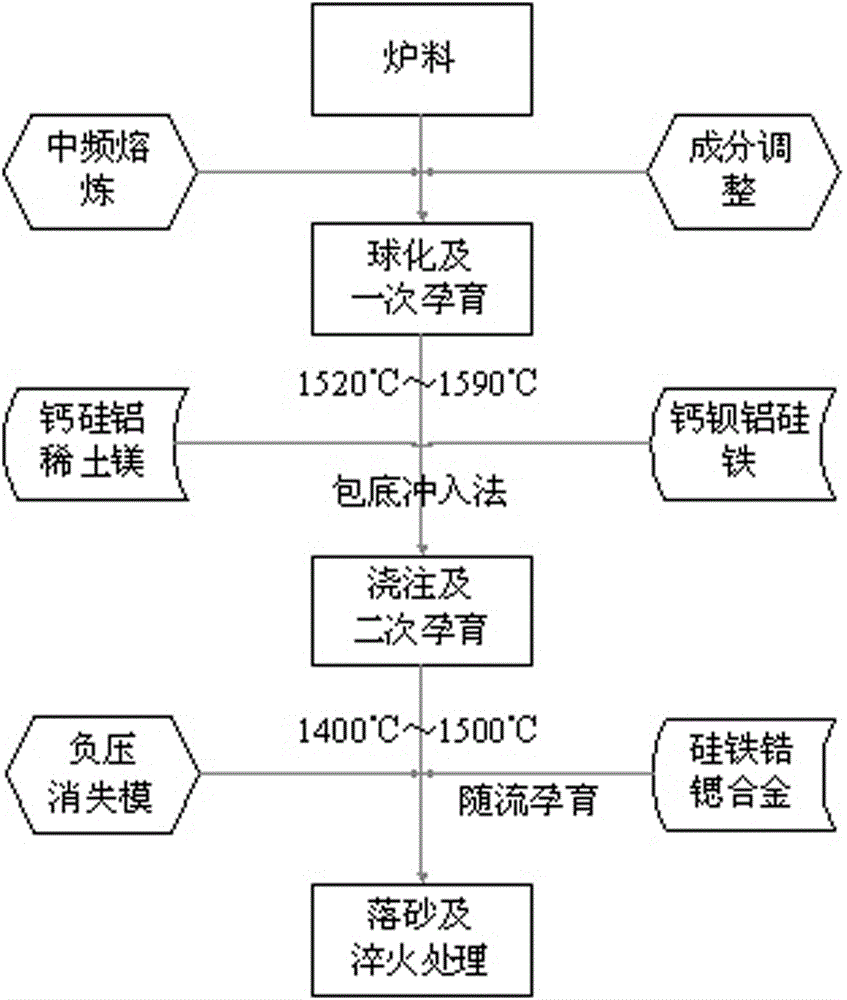

[0064] Embodiment 1: According to the technical proposal of the present invention, put Q235B scrap steel, Q18 pig iron, low-carbon ferromanganese and electrolytic copper into the intermediate frequency induction furnace as furnace materials, and use high-purity electrode carburizers for carburization.

[0065] During the spheroidization inoculation, the bottom-packing method is adopted and 2.0% calcium-silicon-aluminum-rare-earth-magnesium alloy and 0.8% calcium-barium-aluminum-silicon-iron alloy are respectively put in as spheroidizing inoculants, and the spheroidizing temperature is 1550°C; when pouring, 0.5% ferrosilicon-zirconium-strontium alloy is used for flow inoculation, the pouring temperature is 1470°C, and the composition of flow inoculant is Si75.21%, Al0.5%, Zr1.15%, Sr2.03%, Ca0.25% , the rest is Fe; the main chemical components in the final molten iron are: C4.0%, Si2.6%, Mn0.5%, P≦0.05%, S≦0.02%, Cu0.3%.

[0066] The negative pressure lost foam casting process ...

Embodiment 2

[0068] Example 2: Put Q235B steel scrap, Q18 pig iron, low-carbon ferromanganese and electrolytic copper into an intermediate frequency induction furnace as furnace materials, and use high-purity electrode carburizers for carburization.

[0069]During the spheroidization inoculation, the bottom-packing method is adopted and 2.0% calcium-silicon-aluminum-rare-earth-magnesium alloy and 0.8% calcium-barium-aluminum-silicon-iron alloy are respectively put in as spheroidizing inoculants, and the spheroidizing temperature is 1550°C; when pouring, 0.5% ferrosilicon-zirconium-strontium alloy is used for flow inoculation, the pouring temperature is 1450°C, and the composition of flow inoculant is Si75.21%, Al0.5%, Zr1.15%, Sr2.03%, Ca0.25% , the rest is Fe; the main chemical components in the final molten iron are: C4.0%, Si2.6%, Mn0.5%, P≦0.05%, S≦0.02%, Cu0.3%.

[0070] The furan resin sand molding is used for casting, the pouring system adopts the bottom injection process, and the u...

Embodiment 3

[0072] Example 3: Put Q235B steel scrap, Q18 pig iron, low-carbon ferromanganese and electrolytic copper into an intermediate frequency induction furnace as furnace materials, and use a high-purity electrode carburizer for carburization.

[0073] During the spheroidization inoculation, the bottom-packing method is adopted and 2.0% calcium-silicon-aluminum-rare-earth-magnesium alloy and 0.8% calcium-barium-aluminum-silicon-iron alloy are respectively put in as spheroidizing inoculants, and the spheroidizing temperature is 1550°C; when pouring, Use 0.5% 75% ferrosilicon pellets for inoculation with flow, the pouring temperature is 1430°C; the main chemical components in the final molten iron are: C4.0%, Si2.6%, Mn0.5%, P≦0.05 %, S≦0.02%, Cu0.3%.

[0074] The negative pressure lost foam casting process is used for casting, the negative pressure is 0.06MPa, the pressure holding time is 5 minutes, and the unpacking time is 15 minutes.

[0075] The subsoiling shovel tip prepared ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness value | aaaaa | aaaaa |

| Brinell hardness value | aaaaa | aaaaa |

| Brinell hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com