HT250 heat treatment brake drum and fabrication method thereof

A brake drum and process technology, applied in heat treatment equipment, heat treatment furnace, brake drum, etc., can solve problems such as brake drum thermal fatigue cracking, bottoming accidents, brake drum rapid wear, etc., to overcome thermal fatigue cracking life Insufficient, improve the casting yield, the effect of strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

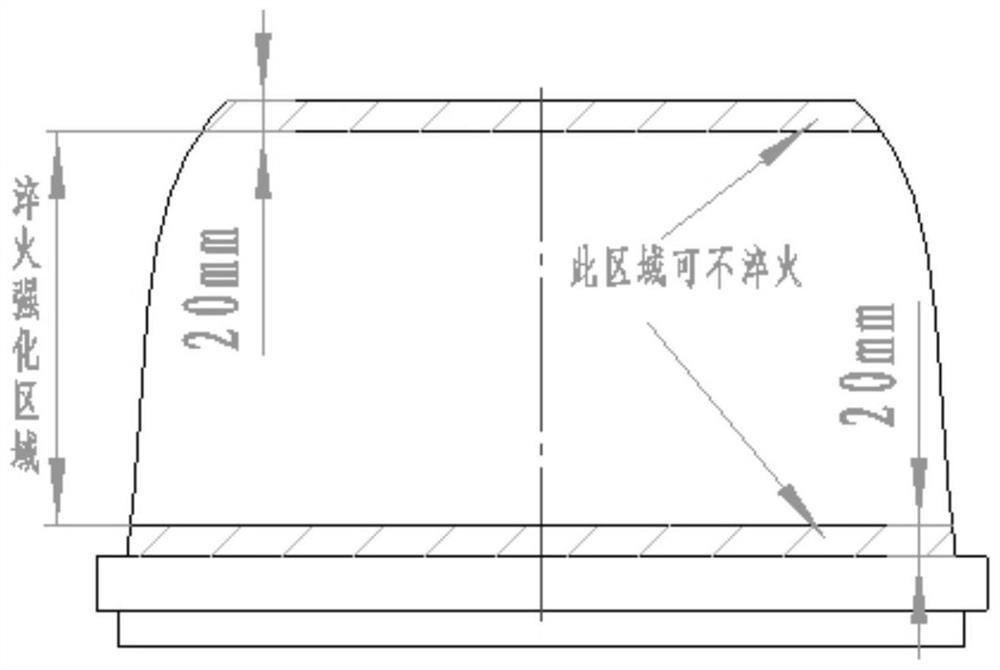

[0026] The embodiment of the present invention provides a preparation method of HT250 heat-treated brake drum, comprising the following steps: providing a preparation method of HT250 heat-treated brake drum, comprising the following steps: adopting induction hardening process, first finishing the surface of HT250 brake drum Heat to 860-920°C, and then continuously spray quenching liquid on the surface of HT250 brake drum precision workpiece until the surface temperature is not higher than 100°C; then place HT250 brake drum precision workpiece at 500-550°C for tempering a lot After 2 hours; finally, place the finished piece of HT250 brake drum in the air and cool it down to room temperature naturally to obtain HT250 heat-treated brake drum.

[0027] The invention adopts HT250 material with high casting yield and good heat dissipation performance to prepare HT250 brake drum precision parts. The surface hardness and tensile strength of the HT250 brake drum precision parts are enha...

Embodiment 1

[0040] The present embodiment provides a kind of HT250 brake drum fine work piece, and its preparation method is as follows:

[0041] (1) Material selection: select HT250 raw materials that meet the requirements of national standards, and the commonly used main chemical components are as follows in terms of weight percentage;

[0042] C Si mn P S 3.3±0.1 1.9±0.1 0.7±0.05 ≤0.1 0.06±0.05

[0043] The rest is Fe and other unavoidable impurities.

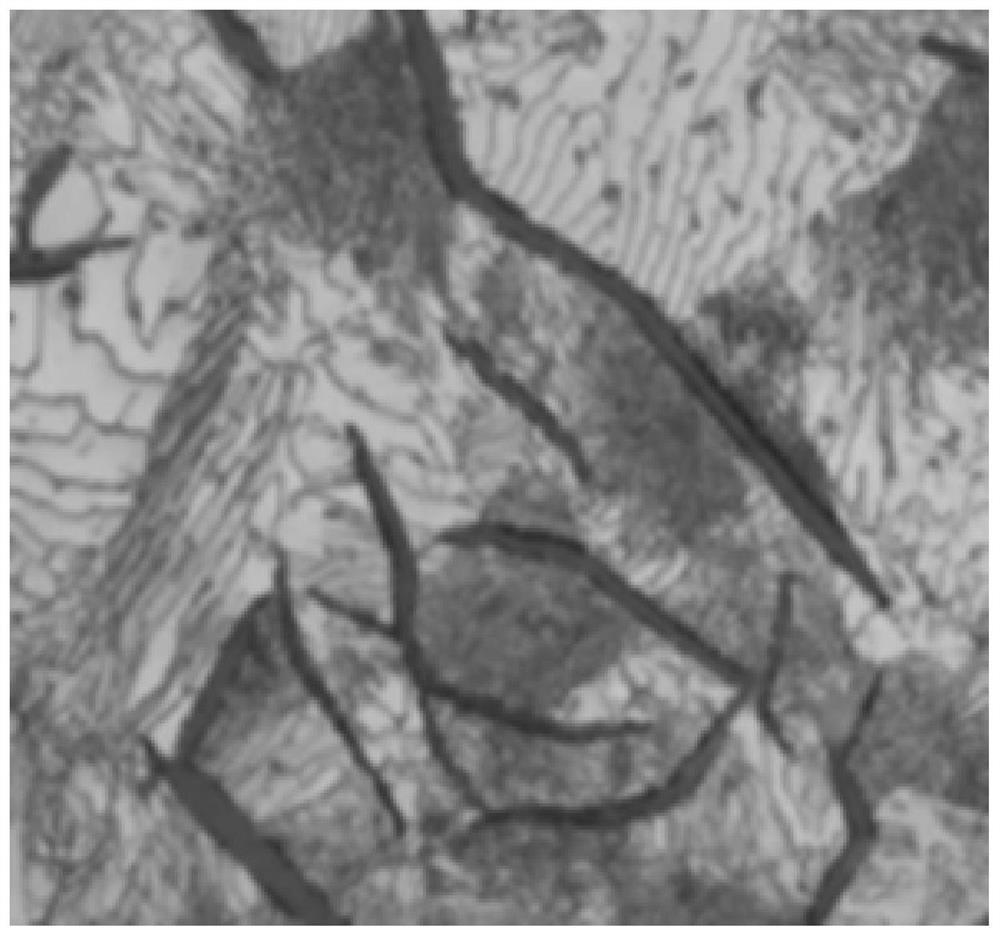

[0044] (2) Casting and processing: According to the national standard GB / T 9439-2010, the HT250 raw material is melted in an electric furnace and cast into a HT250 brake drum rough billet, and then roughed and finished, and a qualified HT250 brake drum is processed. Precision workpiece, its metallographic structure is thicker flaky pearlite + ferrite + flake graphite + carbide.

Embodiment 2

[0046] This embodiment provides a method for preparing a HT250 heat-treated brake drum, comprising the following steps:

[0047] (1) induction hardening

[0048] A multi-turn inductor is used to heat the inner circular surface of the HT250 brake drum precision workpiece provided in Example 1, and at the same time, the HT250 brake drum precision workpiece is rotated to ensure that the inner circular surface is evenly heated; wherein, the frequency of the induction heating current is set to 8kHz , the heating specific power is 1kW / cm 2 , The heating time is 40 seconds. When the inner surface of the HT250 brake drum precision workpiece is heated to 860°C, spray the quenching liquid immediately, and stop spraying the liquid when the inner surface of the HT250 brake drum precision workpiece cools to 100°C; among them, the quenching liquid is PAG with a concentration of 8wt%. quenching agent.

[0049] (2) High temperature tempering

[0050] Put the quenched HT250 brake drum into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com