Die casting rare earth aluminum alloy material with high heat conductivity and preparation method thereof

A technology of aluminum alloy materials and high thermal conductivity, which is applied in the field of aluminum alloy materials, can solve the problems of relying on imports of high thermal conductivity die-casting aluminum alloy materials, and achieve the effects of excellent mechanical properties, excellent mechanical properties, and excellent elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

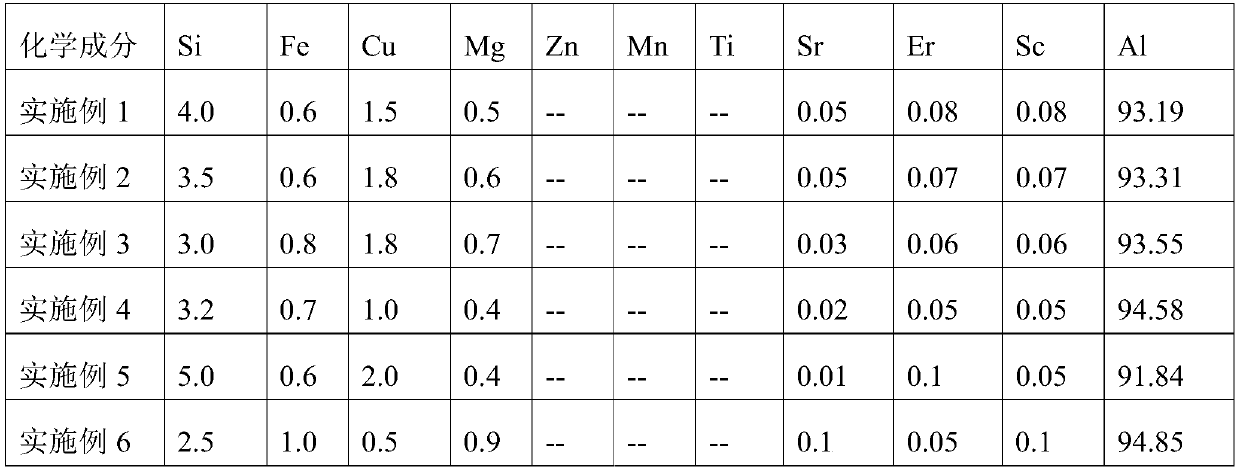

Embodiment 1

[0032] A die-casting rare earth aluminum alloy material with high thermal conductivity, its composition and weight percentage are: Si 4.0%, Fe0.6%, Cu 1.5%, Mg 0.5%, Sr 0.05%, Er 0.08%, Sc 0.08%, and the rest The amount is aluminum.

[0033] Its preparation method comprises the following steps:

[0034] (1) Put the aluminum-iron master alloy, aluminum-silicon master alloy, copper ingot and aluminum ingot into the smelting furnace, the aluminum ingot is placed on the bottom and the top respectively, and the middle is followed by the aluminum-silicon master alloy, the aluminum-iron master alloy and the copper ingot, Set the smelting temperature to 730°C, and obtain melt I after the charge is completely melted;

[0035] (2) Add aluminum-erbium master alloy and aluminum-scandium master alloy to melt I for smelting, set the melting temperature to 730°C, and obtain melt II after the charge is completely melted;

[0036] (3) Add magnesium ingots to melt II for smelting, set the mel...

Embodiment 2

[0041] A die-casting rare earth aluminum alloy material with high thermal conductivity, its composition and weight percentage are: Si 3.5%, Fe 0.6%, Cu 1.8%, Mg 0.6%, Sr 0.05%, Er 0.07%, Sc 0.07%, Yu The amount is aluminum.

[0042] Its preparation method comprises the following steps:

[0043] (1) Put the aluminum-iron master alloy, aluminum-silicon master alloy, copper ingot and aluminum ingot into the smelting furnace, the aluminum ingot is placed on the bottom and the top respectively, and the middle is followed by the aluminum-silicon master alloy, the aluminum-iron master alloy and the copper ingot, Set the melting temperature to 740°C, and melt I is obtained after the charge is completely melted;

[0044] (2) Add aluminum-erbium master alloy and aluminum-scandium master alloy to melt I for smelting, set the melting temperature to 740°C, and obtain melt II after the charge is completely melted;

[0045] (3) Add magnesium ingots to melt II for smelting, set the melting ...

Embodiment 3

[0050] A die-casting rare earth aluminum alloy material with high thermal conductivity, its composition and weight percentage are: Si 3.0%, Fe 0.8%, Cu 1.8%, Mg 0.7%, Sr 0.03%, Er 0.06%, Sc 0.06%, Yu The amount is aluminum.

[0051] Its preparation method comprises the following steps:

[0052] (1) Put the aluminum-iron master alloy, aluminum-silicon master alloy, copper ingot and aluminum ingot into the smelting furnace, the aluminum ingot is placed on the bottom and the top respectively, and the middle is followed by the aluminum-silicon master alloy, the aluminum-iron master alloy and the copper ingot, Set the melting temperature to 750°C, and melt I is obtained after the charge is completely melted;

[0053] (2) Add aluminum-erbium master alloy and aluminum-scandium master alloy to melt I for smelting, set the melting temperature to 750°C, and obtain melt II after the charge is completely melted;

[0054] (3) Add magnesium ingots to melt II for smelting, set the melting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com