Reinforced composite aluminum-based material and preparation method thereof

A technology for compounding aluminum and base materials, which is used in the manufacture of rayon, chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of general reinforcement effect of aluminum-based composite materials, insufficient power, etc., and achieves excellent specific surface area, low cost, and improved The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

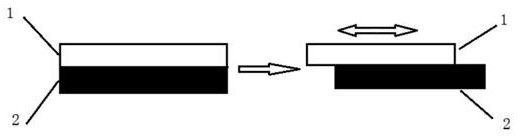

Image

Examples

Embodiment 1

[0034] Ce-C-SiC@Al 2 o 3 The preparation method of the reinforced phase is:

[0035] S1. Dissolve polycarbosilane in xylene, prepare polycarbosilane solution according to the ratio of polycarbosilane and xylene at 1.2 g / mL, and ultrasonically disperse for 30 minutes to obtain a spinning solution;

[0036] S2. Weigh La 2 o 3 Fully dissolve with concentrated nitric acid, remove excess nitric acid and then weigh nano-Al 2 o 3 Add the powder and absolute ethanol to the above beaker to form a mixed solution, place the solution on a magnetic stirrer and stir for 2 hours to make the solution evenly mixed;

[0037] S3. Preparation of composite fibers by electrospinning. The spinning process parameters include: using a needle with an inner diameter of 0.8mm, a voltage of 12kV, a distance from the needle to the receiving screen of 15cm, and a spinning supply rate of 20ul / min;

[0038] S4. Place the composite fiber prepared in the above steps in an oven at 100°C for aging for 50 ho...

Embodiment 2

[0040] Ce-C-SiC@Al 2 o 3 The preparation method of the reinforced phase is:

[0041] S1. Dissolve polycarbosilane in xylene, prepare a polycarbosilane solution according to the ratio of polycarbosilane and xylene to 1.5 g / mL, and disperse it ultrasonically for 60 minutes to obtain a spinning solution;

[0042] S2. Weigh La 2 o 3 Fully dissolve with concentrated nitric acid, remove excess nitric acid and then weigh nano-Al 2 o 3 Add the powder and absolute ethanol to the above beaker to form a mixed solution, place the solution on a magnetic stirrer and stir for 2 hours to make the solution evenly mixed;

[0043]S3. Preparation of composite fibers by electrospinning. The spinning process parameters are as follows: use a needle with an inner diameter of 1.2mm, a voltage of 25kV, a distance from the needle to the receiving screen of 25cm, and a supply rate of 40ul / min for spinning;

[0044] S4. Place the composite fiber prepared in the above steps in an oven at 120° C. for ...

Embodiment 3

[0046] Ce-C-SiC@Al 2 o 3 The preparation method of the reinforced phase is:

[0047] S1. Dissolve polycarbosilane in xylene, prepare a polycarbosilane solution according to the ratio of polycarbosilane and xylene to 1.25g / mL, and disperse it ultrasonically for 40min to obtain a spinning solution;

[0048] S2. Weigh La 2 o 3 Fully dissolve with concentrated nitric acid, remove excess nitric acid and then weigh nano-Al 2 o 3 Add the powder and absolute ethanol to the above beaker to form a mixed solution, place the solution on a magnetic stirrer and stir for 2 hours to make the solution evenly mixed;

[0049] S3. Prepare composite fibers by electrospinning. The spinning process parameters include: using a needle with an inner diameter of 1.0mm, a voltage of 15kV, a distance from the needle to the receiving screen of 18cm, and a spinning supply rate of 28ul / min;

[0050] S4. Place the composite fiber prepared in the above steps in an oven at 105°C for aging for 40 hours, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com