Method for recycling waste epoxy resin

A technology of epoxy resin and recycling method, which is applied in the direction of plastic recycling, recycling technology, reagents, etc., can solve the problems of difficult recycling of waste epoxy resin, affecting the mechanical properties of materials, and serious environmental pollution, etc., and achieves the improvement of mechanical strength and protection The effect of improving the combination of environment and interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

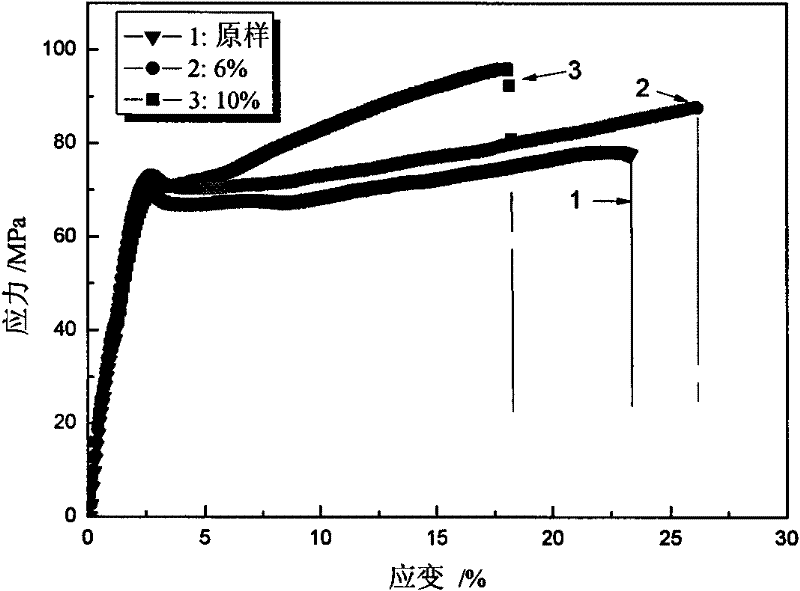

[0025] Choose waste epoxy insulators, crush them with a pulverizer, pass through a sieve with a pore size of 2.5 microns, and select waste epoxy resin particles with a particle diameter of less than 2.5 microns (re-grind those larger than 2.5 microns), and put them into The mass ratio of TEOS: KH560 is 1:1, and the mass ratio of TEOS: absolute ethanol is 1:1.5, add 1.5% hydrochloric acid, stir at room temperature for 5 minutes, take out and drain, and place under atmospheric conditions After more than 48 hours, mix the waste epoxy resin particles with the mass content of waste particles of 0%, 3%, 6% and 10% respectively with the new epoxy resin particles, and then add a curing agent to cure and form. After the obtained material is tested for mechanical properties, the results of its mechanical properties are as follows: figure 1 Shown (the percentage content of the label in the figure is the mass percentage content of the pulverized particles of waste epoxy resin added). Whe...

Embodiment 2

[0027] Select waste and old epoxy insulators, use a pulverizer to crush them, pass through a sieve with an aperture of 2.5 microns, select waste and old epoxy resin particles with a particle diameter of less than 2.5 microns, and put them into TEOS:KH560 with a mass ratio of 4:4~ 6. Add 1.5% p-toluenesulfonic acid to a solution with a ratio of TEOS and absolute ethanol of 1:2~5, stir at room temperature for 5 minutes, take it out and drain it, and place it under atmospheric conditions for more than 48 hours. The waste epoxy resin particles with the mass content of the waste particles being 0 and 6% respectively are combined with the new epoxy resin particles and then cured and formed. The high resistance meter tests the volume resistivity of the prepared materials, and the volume resistivity of the material with a waste and old epoxy resin content of 6% is basically close to that of a waste and old epoxy resin content of 0% (new product), both within 10 15 Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com