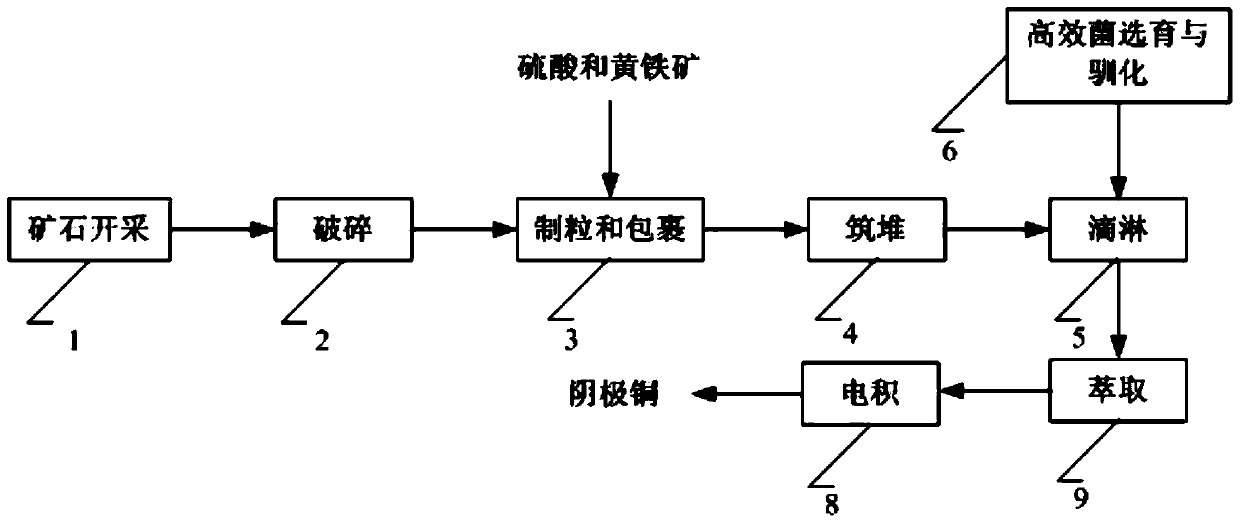

High-efficiency sulfur-oxidizing bacteria and a process for rapid heating of low-sulfur copper ore leaching in alpine regions

A technology of sulfur oxidizing bacteria and sulfur oxidizing acid, which is applied to the process of rapid heating in the leaching process of low-sulfur copper ore in alpine regions, and the field of high-efficiency sulfur oxidizing bacteria, can solve the problems of slow leaching rate, low temperature, poor permeability, etc., and achieve a short process. , The effect of simple equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The ore used comes from a copper mine in Tibet. The temperature in the mining area is low, and the maximum temperature is lower than 30°C. The main element analysis of the copper mine is shown in Table 1, and the main mineral composition containing copper is shown in Table 2.

[0036] Table 1 Multi-element analysis

[0037] element name Cu Fe Mg Ca S SiO 2

content(%) 0.75 4.21 2.14 1.56 0.48 76.54

[0038] Table 2 Phase analysis of copper minerals

[0039] Copper in copper oxide copper in secondary copper sulfide copper in primary copper sulfide copper in silicate Occupancy / wt% 53.67 15.49 29.58 1.26

[0040] The valuable metal element of this ore is copper, which is a typical oxygen-sulfur mixed ore with low sulfur content. Using traditional flotation, the recovery rate is low, and using conventional sulfuric acid leaching, the copper sulfide ore part is difficult to leaching, and the copper leach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com