Recycling system and method for gas waste heat of coal water slurry gasification

A technology for gasification of coal gas and waste heat recovery, which is applied in gasification process, granular/powdered fuel gasification, chemical industry, etc., and can solve the problems of low recovery and utilization rate of waste heat from coal-water slurry gasification, environmental protection, and non-energy saving. , to achieve the effect of improving cold gas efficiency, easy operation, and increasing effective gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

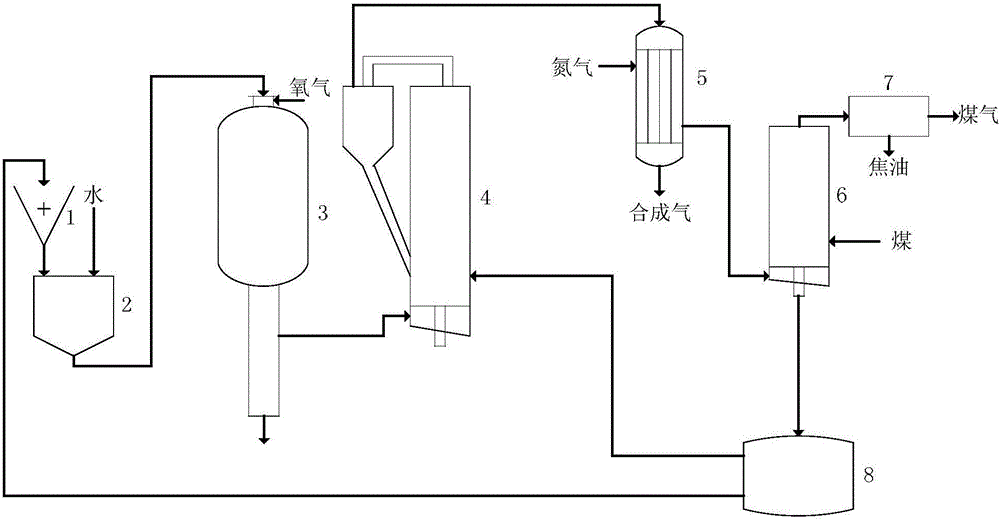

[0037] The high-temperature gas produced by the coal-water slurry gasifier enters the fluidized bed gasifier at 1300 ° C, and the gas contains about 15% CO 2 and 10% H 2 O, H in the gas under the condition of high temperature waste heat of the gas 2 O and CO 2 Carry out C+CO 2 =2CO; C+H 2 O=CO+H 2 reaction. Syngas limited components CO, H 2 content increased by 5%. After passing through the fluidized bed gasification device 4, the temperature of the gas is reduced to 950°C, and the gas passes through the gas heat exchanger to preheat the nitrogen, and the temperature of the gas is further reduced to 600°C. The gas preheated by the gas preheats the nitrogen to 550°C, and the nitrogen is sent into the fluidized bed pyrolyzer as the heat carrier of the long-flame coal pyrolysis. The oil-gas mixture produced by pyrolysis is sent to the oil-gas condensing device for condensation to obtain additional products such as oil and gas. The pyrolyzed semi-coke enters the semi-coke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com