An epoxy resin composition and prepregs and laminates using the same

A technology of epoxy resin and tough epoxy resin, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve low water absorption, heat and humidity resistance, dielectric properties, and incomplete phase separation , poor dielectric properties, etc., to improve toughness and processability, increase glass transition temperature, and excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

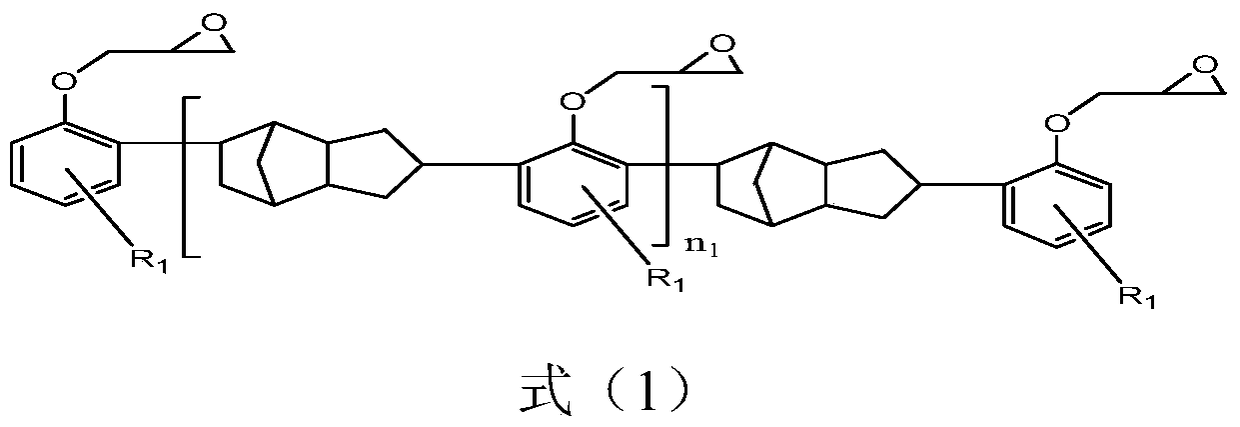

[0082] Preparation example: the synthesis of novolac epoxy resin with formula (6) structure

[0083] Add 200g of bisphenol A to a four-necked flask (500mL) equipped with a stirrer, a thermometer, and a condensing reflux device, and dissolve it in a water bath, weigh 2.0g of boron trifluoride ether, add it to a 500mL four-necked flask, and drop Add 60g of dicyclopentadiene to the liquid funnel, and control the dropping rate so that all the dicyclopentadiene is added dropwise within 2 hours, and the temperature is raised to 100°C, kept for 4 hours, and the reaction is completed, washed with water, filtered, recrystallized, and vacuum-dried. A phenolic resin of the following structure was obtained.

[0084]

[0085] Put 25g of the phenolic resin with the dicyclopentadiene bisphenol A structure obtained in the previous step into a four-necked flask, then weigh 100.0g of epichlorohydrin and slowly add it. Add 1 mol of NaOH solution with a mass fraction of 33%, control the speed...

Embodiment 1

[0088]Take a container, add 60 parts by weight of NC-3000H, add an appropriate amount of MEK, stir and dissolve, add 25 parts by weight of core-shell rubber toughened epoxy resin MX-395, 10 parts by weight of tetrabromobisphenol A epoxy resin 153, 5 parts by weight of four-functional modified epoxy resin 1031, 14 parts by weight of active ester curing HPC-8000-65T and 26 parts by weight of novolak resin 2812, stirring, adding an appropriate amount of curing accelerator 4-dimethylaminopyridine and 2 -Methyl-4-ethylimidazole, continue to stir evenly, and finally use a solvent to adjust the solid content of the liquid to 60% to 80% to make a glue. Soak the above glue with glass fiber cloth to form the glue. Use glass fiber cloth to impregnate the above glue solution, and control it to an appropriate thickness, then dry to remove the solvent to obtain a prepreg. The prepregs prepared by using several sheets are superimposed on each other, and a copper foil is laminated on both si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com