Polybutylene drainage pipeline material and preparation method thereof

A drainage pipe and polybutene technology, which is applied in the field of materials, can solve the problems of poor mechanical properties and corrosion resistance, and achieve the effects of good mechanical properties, good corrosion resistance, good tensile strength and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

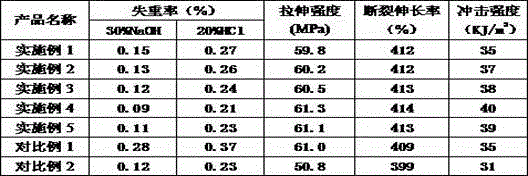

Examples

Embodiment 1

[0017] A polybutene drainage pipe material, comprising in parts by weight: 25 parts of polybutene, 10 parts of polypropylene, 5 parts of polyvinyl alcohol, 1 part of benzoyl peroxide, 0.1 part of propyl gallate, ethylenediamine 0.1 part of disodium tetraacetate, 1 part of N-aminoethylpiperazine, 1 part of triethylenetetramine, 0.5 part of dilauryl thiodipropionate, 0.2 part of butyl benzyl phthalate, 0.1 part of propylene glycol alginate 0.5 parts of diisodecyl phthalate, 1 part of ethylene-vinyl acetate copolymer, 0.2 parts of hydroxypropyl distarch phosphate, and 0.5 parts of phenyl alkylsulfonate.

[0018] The preparation method of the above-mentioned polybutene drainage pipe material is as follows: first mix all the components, add them to a high-speed disperser and disperse for 2 minutes at a speed of 6000rpm, then add the mixed components into a double-roller open mill, and heat at a temperature of 90 Open the mill for 5 minutes at ℃, the speed ratio of the front roll an...

Embodiment 2

[0020] A polybutene drainage pipe material, comprising in parts by weight: 27 parts of polybutene, 12 parts of polypropylene, 6 parts of polyvinyl alcohol, 1.3 parts of benzoyl peroxide, 0.12 parts of propyl gallate, ethylenediamine 0.12 parts of disodium tetraacetate, 1.3 parts of N-aminoethylpiperazine, 1.2 parts of triethylenetetramine, 0.6 parts of dilauryl thiodipropionate, 0.3 parts of butyl benzyl phthalate, 0.11 parts of propylene glycol alginate 0.6 parts of diisodecyl phthalate, 1.2 parts of ethylene-vinyl acetate copolymer, 0.3 parts of hydroxypropyl distarch phosphate, and 0.6 parts of phenyl alkylsulfonate.

[0021] The preparation method of the above-mentioned polybutene drainage pipe material is as follows: first mix all the components, add them to a high-speed disperser and disperse for 2.5 minutes at a speed of 6500 rpm, then add the mixed components into a double-roller open mill, and mix them at a temperature of 95 Open the mill for 5.5 minutes at ℃, the spe...

Embodiment 3

[0023] A polybutene drainage pipe material, comprising in parts by weight: 30 parts of polybutene, 15 parts of polypropylene, 7.5 parts of polyvinyl alcohol, 1.5 parts of benzoyl peroxide, 0.15 parts of propyl gallate, ethylenediamine 0.15 parts of disodium tetraacetate, 1.5 parts of N-aminoethylpiperazine, 1.5 parts of triethylenetetramine, 0.75 parts of dilauryl thiodipropionate, 0.35 parts of butyl benzyl phthalate, 0.15 parts of propylene glycol alginate 0.75 parts of diisodecyl phthalate, 1.5 parts of ethylene-vinyl acetate copolymer, 0.35 parts of hydroxypropyl distarch phosphate, and 0.75 parts of phenyl alkylsulfonate.

[0024] The preparation method of the above-mentioned polybutene drainage pipe material is as follows: first mix all the components, add them to a high-speed disperser and disperse them for 2.5 minutes at a speed of 7000 rpm, then add the mixed components into a double-roller open mill, and heat them at a temperature of 100 Open the mill for 6 minutes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com