Additive for magnesium aluminate spinel sintering and application method

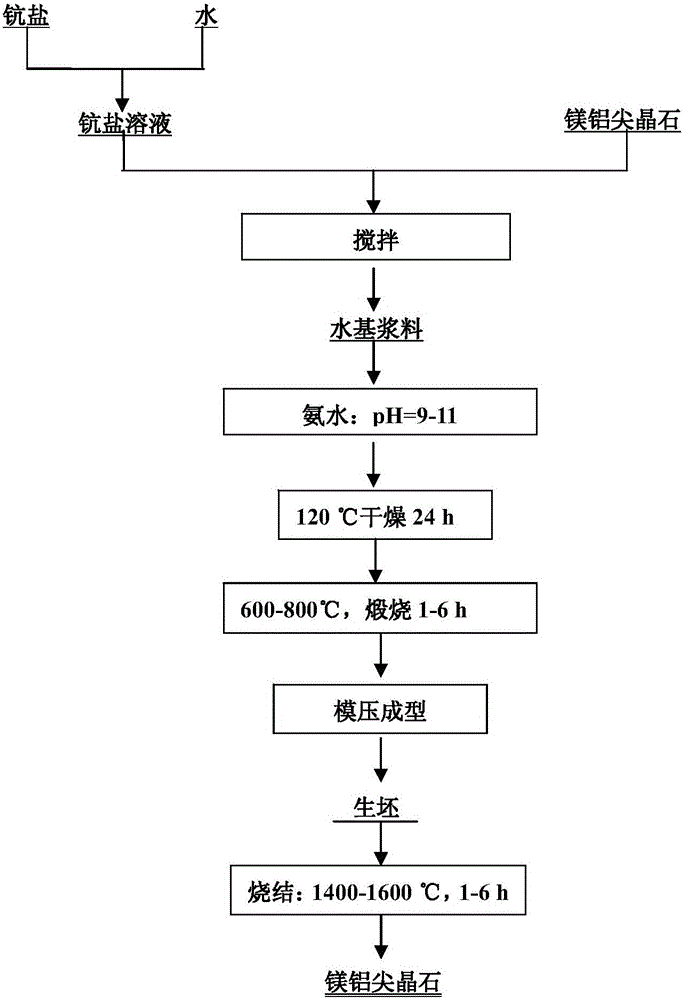

A magnesia-aluminum spinel and additive technology, which is applied in the field of powder metallurgy and can solve the problems of ungrowth and development of magnesia-aluminum spinel grains, excessive growth of magnesia-aluminum spinel grains, uneven distribution of the second phase and the like , to achieve the effect of fine particles, short sintering time and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Scandium chloride (according to 1wt.%Sc 2 o 3 ) into deionized water until completely dissolved. Then 99 wt.% magnesium aluminum spinel was added to the above solution. The pH of the above water-based solution was adjusted to 9.5 with ammonia water, dried at 120° C. for 24 hours, and then calcined at 650° C. for 2 hours. The above-mentioned calcined powder was pressed into shape, and the magnesium-aluminum spar obtained by sintering at 1450° C. for 2 hours had a density of 90% and a bending strength of 150 MPa. Compared with direct compression molding of magnesium aluminum spinel powder without using additives, the density of magnesium aluminum crystal obtained under the same sintering conditions is 70%, and the bending strength is 75MPa.

Embodiment 2

[0028] Scandium nitrate (according to 2wt.%Sc 2 o 3 ) into deionized water until completely dissolved. Then 98 wt.% magnesium aluminum spinel was added to the above solution. The pH of the above water-based solution was adjusted to 10 with ammonia water, dried at 120° C. for 24 hours, and then calcined at 700° C. for 3 hours. The above-mentioned calcined powder was compacted and sintered at 1500° C. for 3 hours to obtain a magnesium-aluminum spar with a density of 92% and a bending strength of 160 MPa. Compared with direct compression molding of magnesium aluminum spinel powder without using additives, the density of magnesium aluminum crystal obtained under the same sintering conditions is 73%, and the bending strength is 83MPa.

Embodiment 3

[0030] Scandium sulfate (according to 4wt.%Sc 2 o 3 ) into deionized water until completely dissolved. Then 96 wt.% magnesium aluminum spinel was added to the above solution. The pH of the above water-based solution was adjusted to 10.5 with ammonia water, dried at 120° C. for 24 hours, and then calcined at 750° C. for 4 hours. The above-mentioned calcined powder was compacted and sintered at 1550° C. for 4 hours to obtain a magnesium-aluminum spar with a density of 95% and a bending strength of 180 MPa. Compared with direct compression molding of magnesium aluminum spinel powder without using additives, the density of magnesium aluminum crystal obtained under the same sintering conditions is 80%, and the bending strength is 95MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com