Preparation method of nitrogen-containing carbon nanotubes wrapped with metal nanoparticles inside

A technology of metal nanoparticles and nanotubes, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of increased production costs, high requirements for corrosion resistance of gas pipelines, and high cost of precursors and other problems, to achieve the effect of easy control, short high temperature treatment time and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

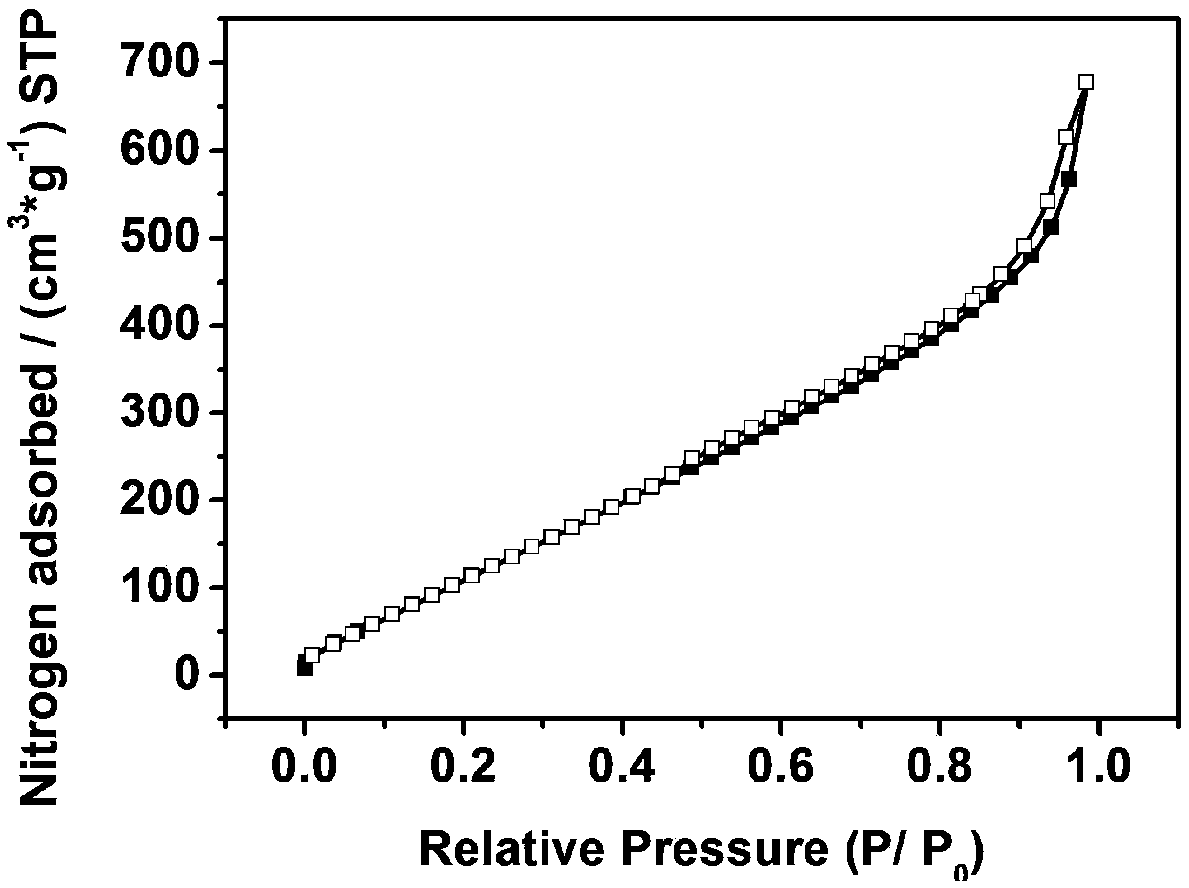

Embodiment 1

[0021] Weigh 2 grams of melamine solid, add 4 milliliters of 36% (mass fraction) formaldehyde solution, and then add 10 milliliters of water to keep the ratio of melamine: formaldehyde: water (mass) 1:0.8:7. Add 10 mg of sodium hydroxide to adjust the pH of the above suspension to alkaline. The suspension was heated to 75°C for 30 minutes to obtain a clear and transparent solution. The solution was cooled to room temperature (20-25 degrees Celsius), and 2.5 ml of acetic acid solution was added dropwise with stirring and continued stirring until a white solid precipitated. The precipitate was separated and dried. Take by weighing 5 grams of ferric chloride hexahydrate and be dissolved in the middle of 100 milliliters of ethanol, add 10 grams of magnesium oxide powders in the solution obtained under stirring condition, keep magnesium oxide: the mass ratio of ferric chloride hexahydrate is 2:1, After vigorous stirring, it was filtered and dried to obtain a reddish-brown solid. ...

Embodiment 2

[0023] Adopting the preparation process of Example 1, the difference is that the mass ratio of ferric chloride hexahydrate to magnesium oxide in the catalyst used is 1:1, and the obtained carbon nanotube diameter becomes thicker, indicating that the morphology of the material is in the Controllable within a certain range. The specific shape of the material is as image 3 shown.

Embodiment 3

[0025] The preparation process of Example 2 is adopted, the difference is that metal ruthenium is loaded on it by impregnation reduction method. The ruthenium nanoparticles can be clearly distinguished under the electron microscope, indicating the operability of the material as a catalyst carrier. The shape of the catalyst is as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com