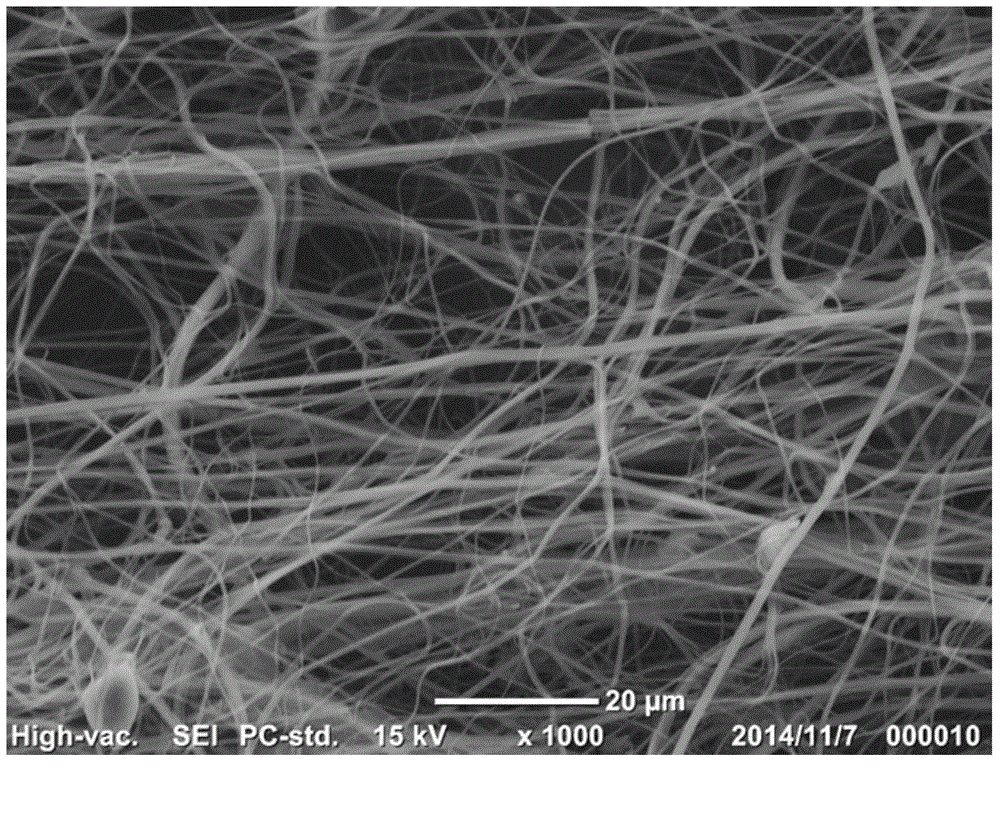

Carbon nanofiber mat, preparation method thereof, and application thereof in all-vanadium redox flow battery

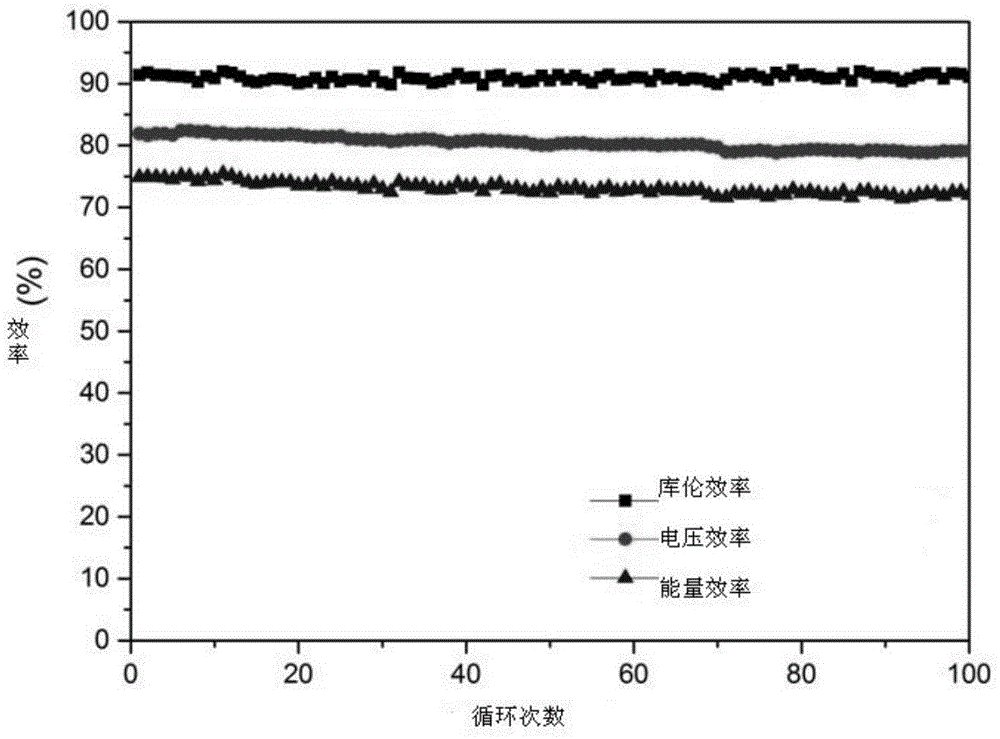

A technology of nano-carbon fiber and fiber felt, which is applied in the direction of nanotechnology, nanotechnology, battery electrodes, etc., can solve the problem of cost-limited large-scale application of electrodes, and achieve good cycle stability, reduce side reactions, and excellent electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Select polyacrylonitrile as the carbon source, dissolve a certain mass of polyacrylonitrile powder in N,N-dimethylformamide solution, wherein the mass fraction of polyacrylonitrile is 10%, stir at 60°C for 8 hours to fully Dissolved to obtain a clear and transparent solution. In addition, polyvinylpyrrolidone is used as a water-soluble polymer, and a certain mass of polyvinylpyrrolidone powder is dissolved in N,N-dimethylformamide solution, wherein the mass fraction of polyvinylpyrrolidone is 20%, and stirred at room temperature 8h to fully dissolve to obtain a clear and transparent solution. Then, 5 mL of the above two solutions were placed in different syringes, and spinning was carried out under the conditions of 10KV voltage, 25° C., and 10% relative humidity, and the distance between the needle tip of the syringe and the receiving plate was 5 cm. Soak the obtained polymer fiber mat in an aqueous solution for 10 hours, then dry it at 110°C for 10 hours, pre-oxidize...

Embodiment 2

[0035] Select polymethyl methacrylate as the carbon source, dissolve a certain mass of polymethyl methacrylate powder in N,N-dimethylformamide solution, wherein the mass fraction of polymethyl methacrylate is 15%, Stir at 50°C for 24h to fully dissolve to obtain a clear and transparent solution. In addition, polyvinyl alcohol is used as a water-soluble polymer, and a certain mass of polyvinyl alcohol powder is dissolved in N,N-dimethylformamide solution, wherein the mass fraction of polyvinyl alcohol is 20%, and stirred at room temperature 8h to fully dissolve to obtain a clear and transparent solution. Then 10mL of the above two solutions were placed in different syringes, and spun under the conditions of 15KV voltage, 25°C, and 20% relative humidity, and the distance between the needle tip of the syringe and the receiving plate was 5cm. The obtained polymer fiber mat was pre-oxidized in air at 200°C for 2h, then sintered at 1000°C for 1h under argon atmosphere, and dried. ...

Embodiment 3

[0037]Polylactic acid was selected as the carbon source, and a certain mass of polylactic acid powder was dissolved in anhydrous ethanolamine solution, wherein the mass fraction of polylactic acid was 20%, and stirred at 55°C for 12 hours to fully dissolve to obtain a clear and transparent solution. In addition, polyvinyl alcohol is used as a water-soluble polymer, and a certain mass of polyvinyl alcohol powder is dissolved in N,N-dimethylformamide solution, wherein the mass fraction of polyvinyl alcohol is 20%, and stirred at room temperature 8h to fully dissolve to obtain a clear and transparent solution. Then 15mL of the above two solutions were placed in syringes, and spinning was carried out under the conditions of 10KV voltage, 25°C, and 15% relative humidity, and the distance between the needle tip of the syringe and the receiving plate was 10cm. The obtained polymer fiber mat was pre-oxidized in air at 300°C for 3h, then sintered at 800°C for 2h under an argon atmosphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com