Separating preparation method of micro droplets and microarrays

A separation method and micro-droplet technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the difficult separation of a large number of micro-droplets and the simple preparation of microarrays, difficult micro-droplets Separation, large volume of micro-droplets and other problems, to achieve the effect of low requirements, less samples and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

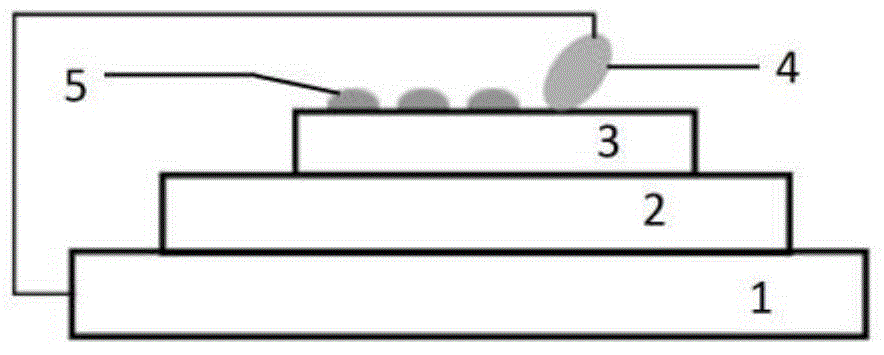

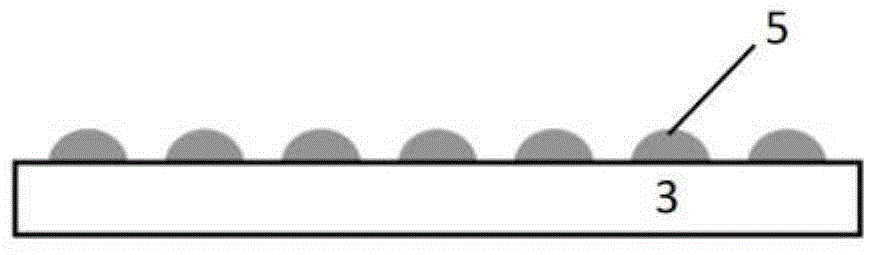

Embodiment 1

[0025] A glycol droplet array was prepared using a drop of glycol solution. The silicon wafer is cleaned, and the specific steps are as follows: the silicon wafer is ultrasonicated three times with acetone and ethanol solutions respectively, and rinsed with deionized water. Then immerse the silicon wafer in a toluene solution with a volume fraction of 1% octadecyltrichlorosilane for 10 minutes, take it out and blow it dry with nitrogen. The whole process is carried out in a clean room to prevent silicon wafers from being polluted by dust in the air. At this time, the contact angle of the silicon wafer was 106°. The preparation of the hydrophilic regions then proceeds. Place the silicon wafer under a photomask, and then expose it to ultraviolet light with a wavelength of 365nm for 10 minutes. During the exposure process, octadecyltrichlorosilane molecules in the light-transmitting region decompose, and this region becomes hydrophilic at the same time. Use a pipette to fix a...

Embodiment 2

[0027] Prepare the dye pattern with a drop of the dye solution. The filter paper commonly used in the laboratory was modified by hydrophobization. The experimental method is as follows: put the filter paper in a clean vacuum desiccator, place a glass slide in it, and drop a drop of perfluorodecyltrimethoxysilane on the glass slide. Then use an oil pump to evacuate the vacuum desiccator for 10 minutes. Then place the desiccator in a 60°C oven for 2 hours. After removal, the static contact angle of the filter paper was 140°. The preparation method of the hydrophilic region of the hydrophobic filter paper is as follows: 5 milliliters of water and 5 milliliters of ethylene glycol are evenly mixed, and a mass fraction of 1% of PAA (molecular weight 3000) is added thereto. After stirring evenly, it can be used as ink for inkjet printing. Print on the hydrophobic filter paper with an inkjet printer, the area where the ink is printed becomes a hydrophilic area, and the area that i...

Embodiment 3

[0029] Preparation of sodium chloride crystals. Hydrophilic substrate preparation: The slides were sonicated three times with ethanol and acetone, rinsed with distilled water, and dried with nitrogen. The whole process is carried out in a clean room to ensure that the surface of the glass sheet is not polluted by impurities in the air. The surface is then patterned with hydrophobic Teflon by microfabrication. The pattern thickness is between 50 nanometers and 10 micrometers. At this time, the surface covered by Teflon is a hydrophobic region, and the region not covered by the Teflon surface is a hydrophilic region. A drop of saturated sodium chloride solution was fixed with a dropper, and the pressure of 200 μN and the speed of 1 mm / s were slid on the surface of Teflon / hydrophilic glass with hydrophilic and hydrophobic patterns. Teflon surface has little adhesion to saturated sodium chloride solution, and hydrophilic glass sheet has strong adhesion to saturated sodium chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com