Pretreatment method and system for spent catalyst containing noble metal

A technology for waste catalysts and precious metals, which is applied in the field of pretreatment of waste catalysts, can solve the problems of adverse effects of dust environment and low recovery rate of precious metals, and achieve the effects of favorable extraction rate, large recovery volume and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

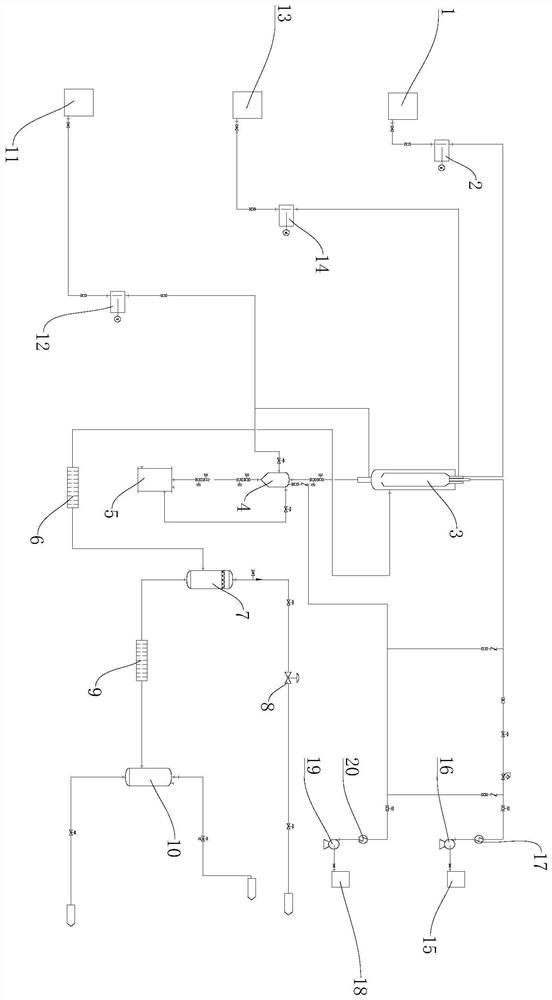

Image

Examples

Embodiment 1

[0026] A catalyst containing noble metal Pt, where the weight percentage of Pt in the catalyst is 25%.

[0027] The catalyst particles are ground and mixed with water to form a slurry with a mass concentration of 10%. The slurry storage tank 1 for storing the slurry is stirred, and the particles are placed to settle. The slurry in the slurry storage tank 1 is pressured by the high-pressure diaphragm pump 2. rise to 25MPa, while the liquid oxygen passes through the high-pressure liquid oxygen pump 16 and the vaporizer, the pressure rises to 25MPa, and the slurry and high-pressure oxygen enter the supercritical water oxidation reactor 3 after being mixed at the nozzle. The temperature in the hearth of the reaction furnace was detected and controlled at 680°C.

[0028] The supercritical water oxidation reaction is an exothermic reaction. When it is detected that the reaction temperature exceeds 680°C, cold water is sent to the furnace of the reactor 3 through the high-pressure pu...

Embodiment 2

[0036] A catalyst containing noble metal Pd, where the weight percentage of Pd in the catalyst is 20%.

[0037] The catalyst particles are ground and mixed with water to form a slurry with a mass concentration of 15%. The slurry storage tank 1 for storing the slurry is stirred, and the particles are placed to settle. The slurry in the slurry storage tank 1 is pressured by the high-pressure diaphragm pump 2. The pressure rises to 27MPa, while the liquid oxygen passes through the high-pressure liquid oxygen pump 16 and the vaporizer, and the pressure rises to 27MPa. The slurry and high-pressure oxygen are mixed at the nozzle and then enter the supercritical water oxidation reactor 3. The temperature in the hearth of the reaction furnace was detected and controlled at 600°C.

[0038] The reaction product of the supercritical water oxidation reaction enters the shell of the reactor 3 from the discharge port of the furnace, and the cooling water is sent to the reactor 3 to contro...

Embodiment 3

[0044] A catalyst containing noble metal Rh, wherein Ph accounts for 20% by weight of the catalyst.

[0045] The catalyst particles are ground and mixed with water to form a slurry with a mass concentration of 8%. The slurry storage tank 1 for storing the slurry is stirred, and the particles are placed to settle. The slurry in the slurry storage tank 1 is pressured by the high-pressure diaphragm pump 2. The pressure rises to 26MPa, while the liquid oxygen passes through the high-pressure liquid oxygen pump 16 and the vaporizer, and the pressure rises to 26MPa. The slurry and high-pressure oxygen enter the supercritical water oxidation reactor 3 after being mixed at the nozzle. The temperature in the hearth of the reaction furnace is detected and controlled at 750°C.

[0046] The reaction product of the supercritical water oxidation reaction enters the shell of the reactor 3 from the discharge port of the furnace, and the cooling water is sent to the reactor 3 to control the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com