A device with a packaging structure of a Love wave sensor

A packaging structure and sensor technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of increased insertion loss, decreased sensor repeatability, accuracy and reliability, difficulty in protecting interdigital transducers, etc., to achieve improved repeatability Sexuality, consumption saving and loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

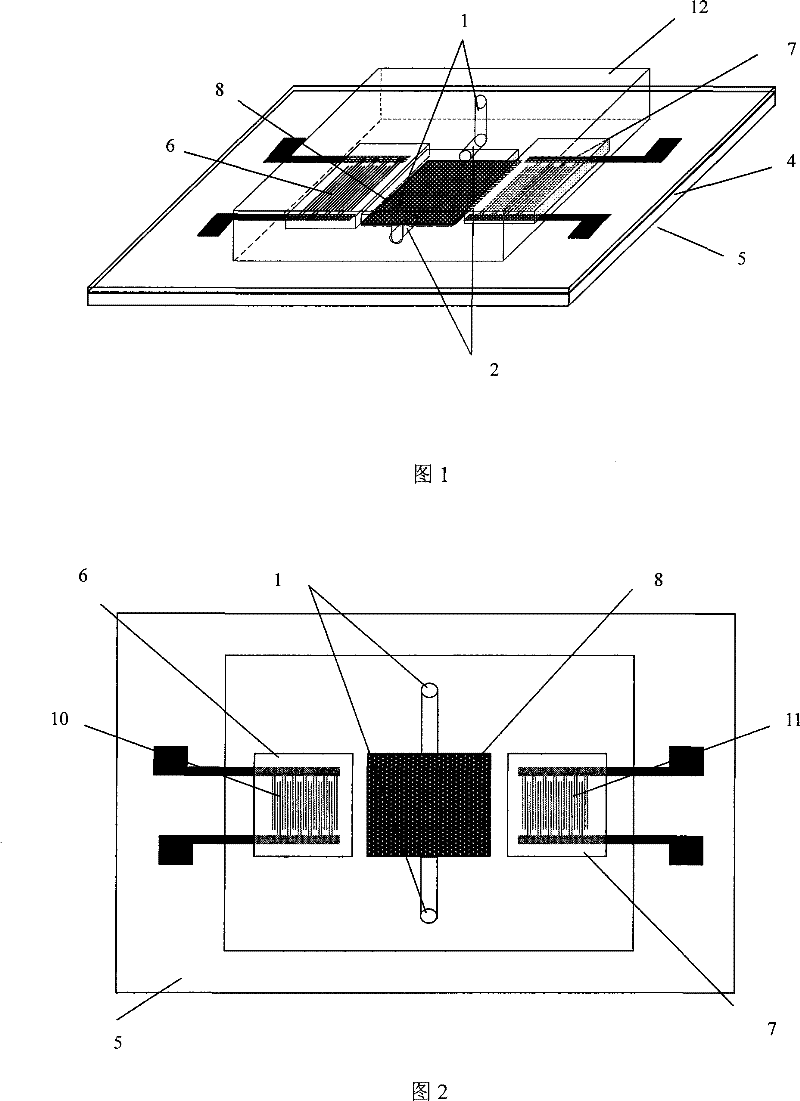

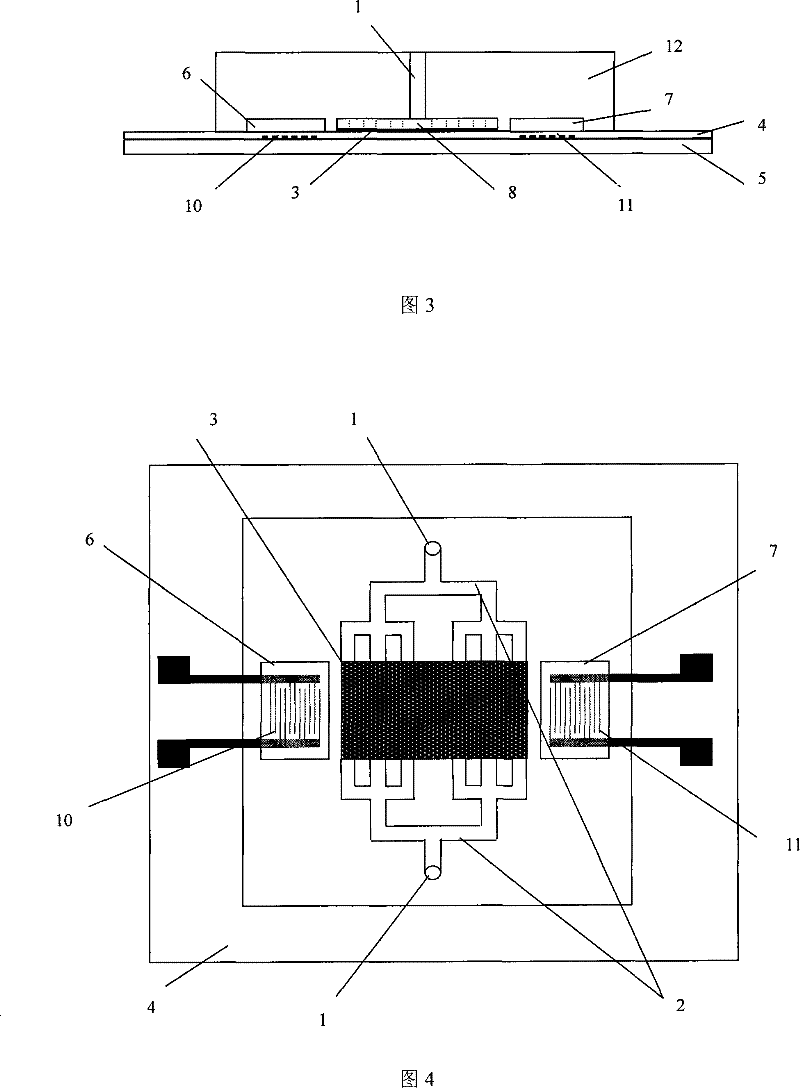

[0028] Specifically make the structure according to the technical scheme of the present invention, see Figure 1~3 , consists of Love wave sensor and microfluidic chip.

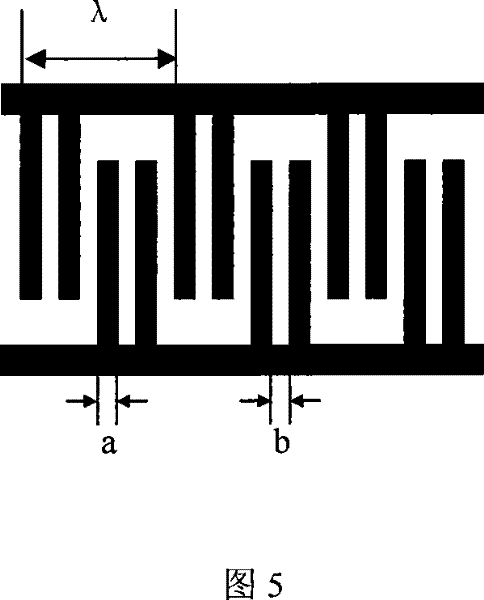

[0029] Love wave sensor structures such as image 3 As shown, it includes: a piezoelectric substrate 5 , a covering waveguide layer 4 , a sensitive film 3 , an input IDT 10 and an output IDT 11 . In this embodiment, the piezoelectric substrate of the Love wave sensor is made of St-cut 90-degree quartz material with a thickness of 0.5mm; the input and output interdigital transducers 10, 11 all adopt a split-finger structure, such as Figure 5 As shown, the period λ is 40 microns, the number of periods is 60, the material of the fingers is aluminum, the thickness of the fingers is 1500 angstroms, the width a of the fingers and the spacing b of the fingers are both one-eighth wavelength; the aperture is 2 mm; Transducer center frequency f 0 =124 MHz; the waveguide layer 4 is made of silicon dioxide, with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com