Free-fall mixed powder gas atomization water-cooled quick-setting magnetic abrasive preparation equipment

A magnetic abrasive and gas atomization technology, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of difficult flow, low life of magnetic abrasive, high scrap rate, etc., and achieve the effect of simple use method and stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention is further described below in conjunction with accompanying drawing:

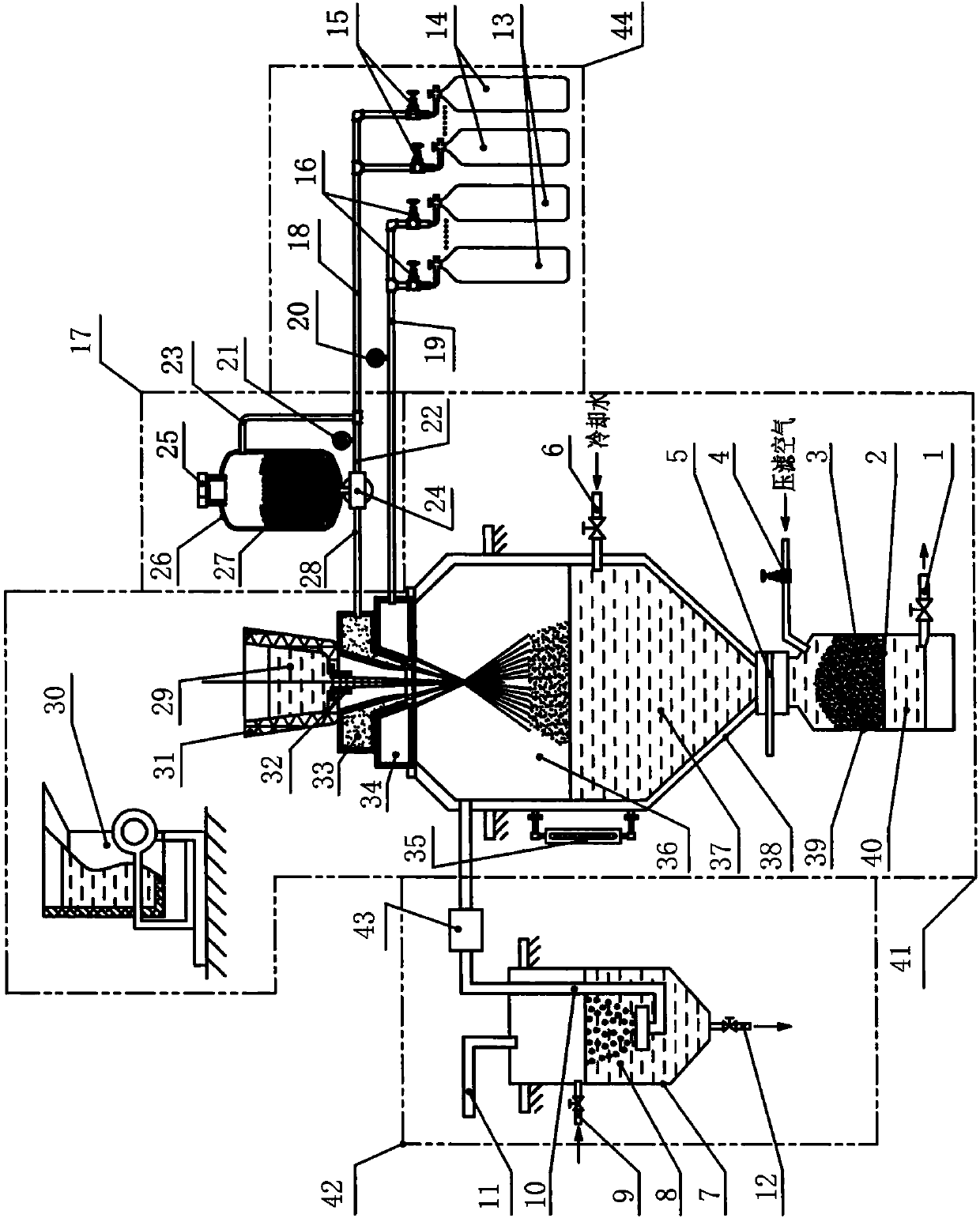

[0057] as attached figure 1 The free-fall powder mixing gas atomization water-cooling fast-setting magnetic abrasive preparation equipment shown includes a double-nozzle atomization water cooling device (41), a screw powder mixer (17), a water seal dust removal device (42), a gas station (44 ).

[0058] attached figure 1 The shown double-nozzle atomizing water cooling device (41) includes: molten metal (29), electric furnace (30), heat preservation crucible (31), metal liquid guide tube (32), low-pressure powder mixing jet nozzle (33), high-pressure Airflow nozzle (34), water level gauge (35), atomizing water cooling chamber (36), cooling water (37), atomizing water cooling chamber housing (38), magnetic abrasive tank (39), filtered water (40), drain water Valve (1), filter screen (2), magnetic abrasive (3), pressure filter air valve (4), gate valve (5), cold water valve (6);...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com