A kind of preparation method of hot straightening roll for medium and thick plate

A technology of thermal straightening rolls and rear rolls, which is applied to heat treatment equipment, rolls, heat treatment furnaces, etc., can solve the problems of restricting the production efficiency of medium and thick plates, large changes in surface hardness, and structural defects in the surfacing layer, etc. Effects of energy consumption and cost, uniform structure, and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for preparing a plate heat straightening roll, comprising the following steps:

[0055] The first step, steel for smelting roll billet:

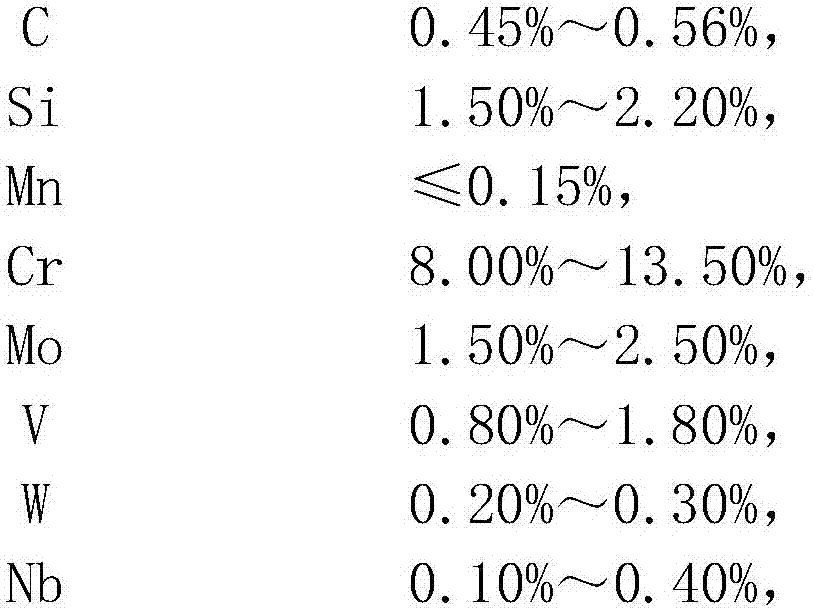

[0056] The percentage by weight of each component in the described roll base steel is:

[0057]

[0058] During implementation, unavoidable impurities (Mn, S, P, Ni, Cu) are allowed in the above components, but effective control of impurities is still required.

[0059] The second step, ladle refining:

[0060] The ladle refining furnace is used to refine the molten steel produced in the first step, and the molten steel is degassed under vacuum conditions;

[0061] The third step, ingot casting:

[0062] Ingot casting under the protection of inert gas;

[0063] The fourth step, forging roll blank:

[0064] The roll billet is manufactured by forging process using the ingot obtained in the previous step, using a 6,000-ton press, with a forging compression ratio of 4.5; the forging process is: heating at 1160°C, the init...

Embodiment 2

[0079] A method for preparing a plate heat straightening roll, comprising the following steps:

[0080] The first step, steel for smelting roll billet:

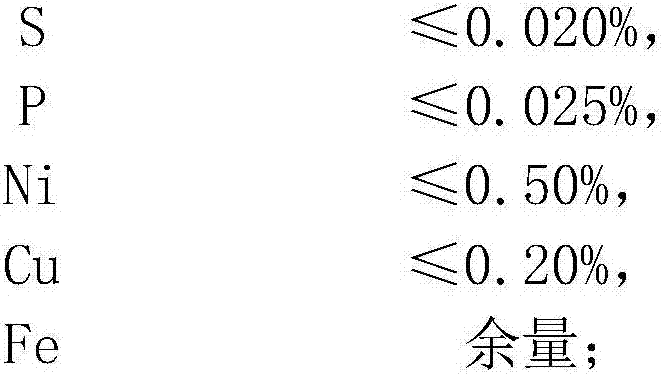

[0081] The percentage by weight of each component in the described roll base steel is:

[0082]

[0083]

[0084] The second step, ladle refining:

[0085] The ladle refining furnace is used to refine the molten steel produced in the first step, and the molten steel is degassed under vacuum conditions;

[0086] The third step, ingot casting:

[0087] Ingot casting under the protection of inert gas;

[0088] The fourth step, forging roll blank:

[0089] The roll billet is manufactured by forging process using the ingot obtained in the previous step, using a 6,000-ton press, with a forging compression ratio of 5; the forging process is: heating at 1100°C, the initial forging temperature is 1100°C, and the final forging temperature is 900°C;

[0090] Annealed immediately after forging;

[0091] The fifth step, surfac...

Embodiment 3

[0105] A method for preparing a plate heat straightening roll, comprising the following steps:

[0106] The first step, steel for smelting roll billet:

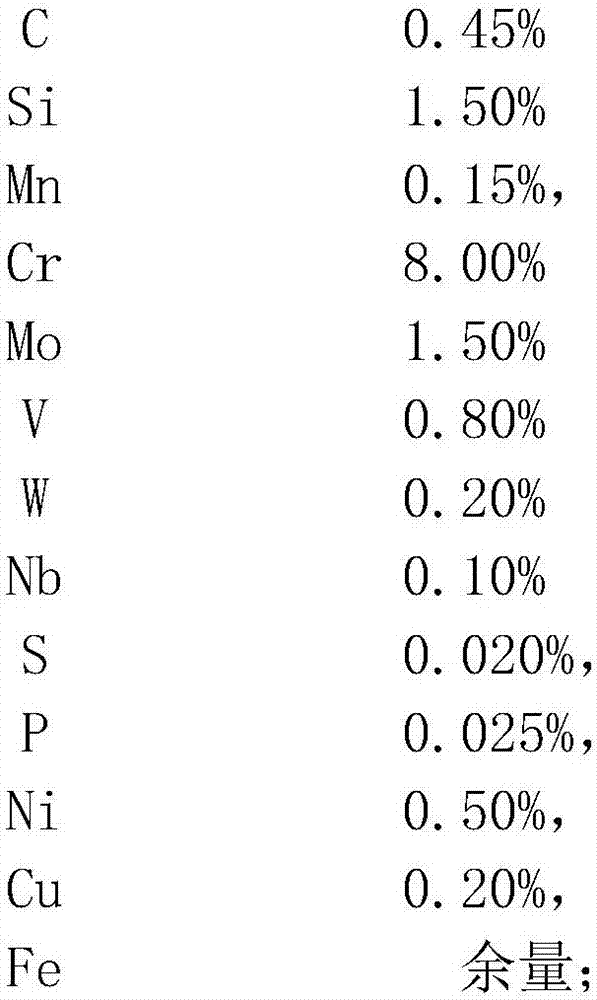

[0107] The percentage by weight of each component in the described roll base steel is:

[0108]

[0109] The second step, ladle refining:

[0110] The ladle refining furnace is used to refine the molten steel produced in the first step, and the molten steel is degassed under vacuum conditions;

[0111] The third step, ingot casting:

[0112] Ingot casting under the protection of inert gas;

[0113] The fourth step, forging roll blank:

[0114] The roll billet is manufactured by forging process using the ingot obtained in the previous step, using a 6,000-ton press, and the forging compression ratio is greater than 4; the forging process is: heating at 1160°C, the initial forging temperature is 1090°C, and the final forging temperature is 950°C;

[0115] Annealed immediately after forging;

[0116] The fifth step, surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com