A kind of hydrophobic resin oily adsorption material and its preparation method

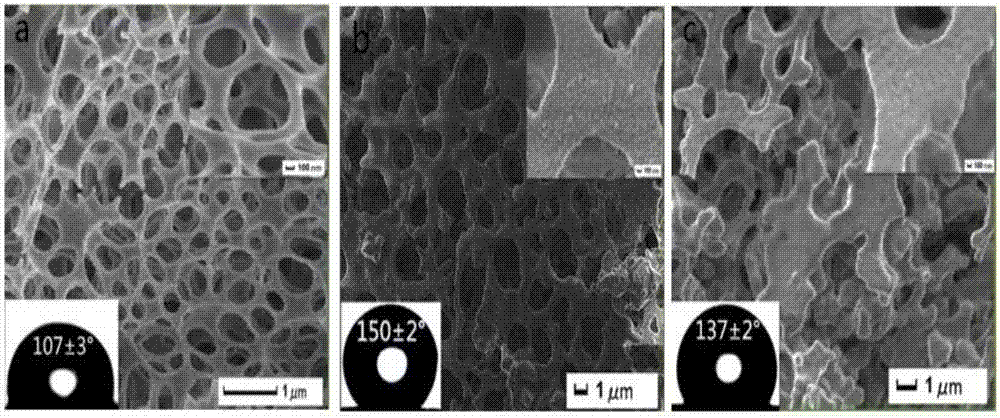

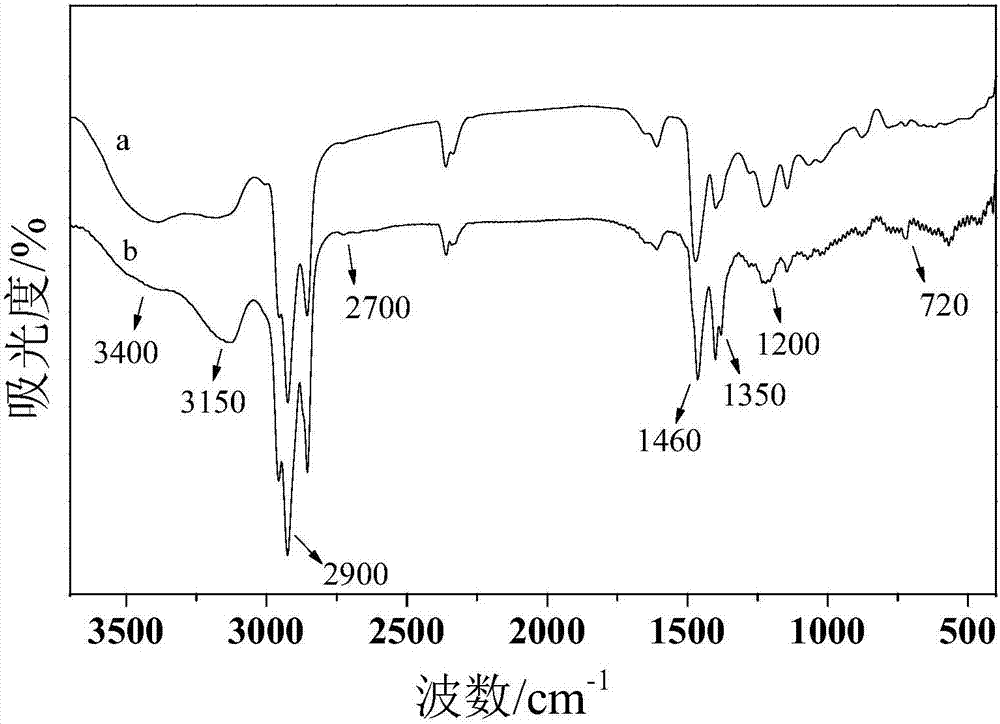

A hydrophobic resin and adsorption material technology, which is applied in the field of environmental functional material preparation, can solve the problems of insufficient material porosity, difficulty in selective adsorption of oil and water, etc., and achieve the effects of increased specific surface area, strong selective adsorption, and improved oil absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of phenolic resin prepolymer

[0029] Take about 2.4g of solid phenol into a round bottom flask and heat it up to 43°C to melt into a liquid state, add a certain amount of sodium hydroxide solution (0.02g / mL), start stirring for about 10min, drop by drop while stirring Add 5 mL of formaldehyde solution dropwise, stir well for 5 min, then raise the temperature to 73°C for one hour reaction.

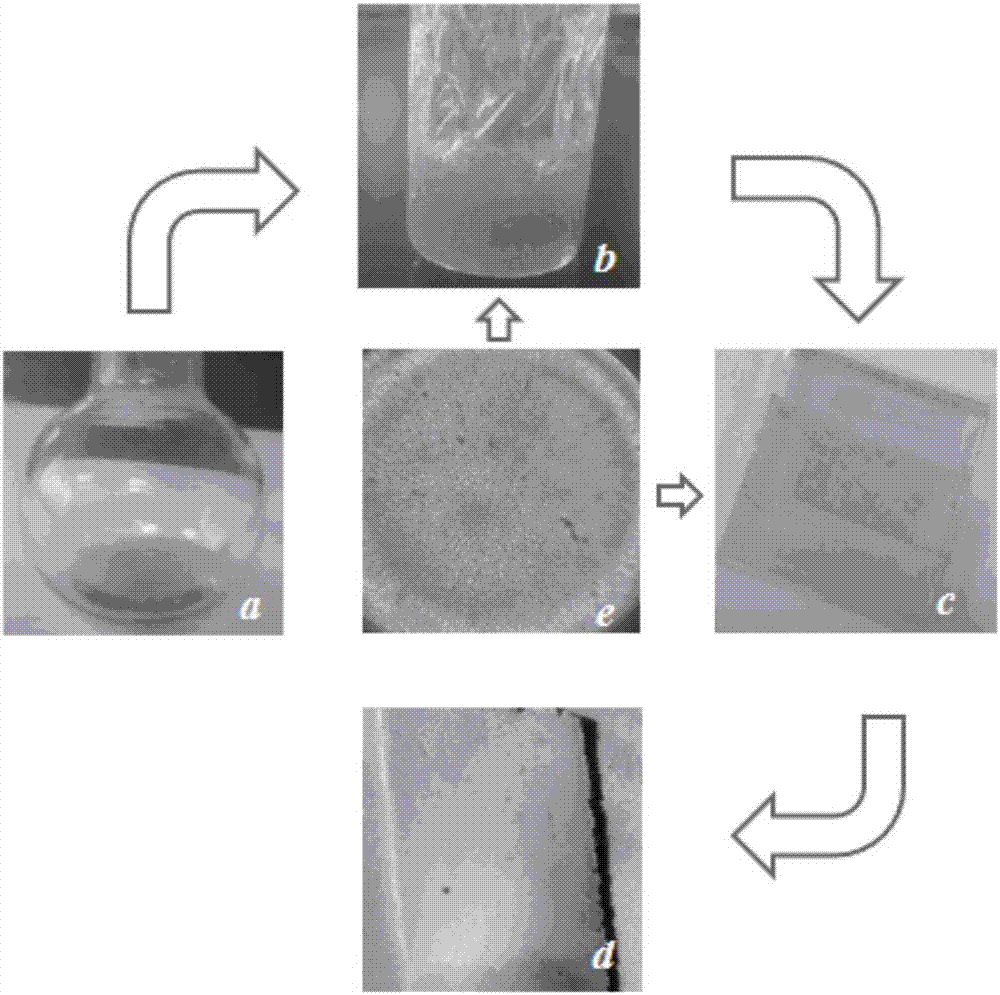

[0030] (2) Preparation of porous resin material by high internal phase emulsion polymerization

[0031] 1) Preparation of O / W type high internal phase emulsion

[0032] Under mechanical stirring, take 4mL of the prepared phenolic resin prepolymer, 0.1g N,N-methylenebisacrylamide (MBA), 0.01g sodium persulfate (SPS, Na 2 S 2 o 8 ), added to a 100mL three-necked flask and mixed thoroughly, added dropwise 850.1g of surfactant Tween, stirred at 900-1100rpm to obtain the water phase; then, continued to stir at 400-600rpm, and added 12mL of liquid Paraffin, stirring con...

Embodiment 2

[0041] (1) Preparation of phenolic resin prepolymer

[0042] Take about 2.4g of solid phenol into a round bottom flask and heat it up to 43°C to melt into a liquid state, add a certain amount of sodium hydroxide solution (0.02g / mL), start stirring for about 10min, drop by drop while stirring Add 5 mL of formaldehyde solution dropwise, stir well for 5 min, then raise the temperature to 73°C for one hour reaction.

[0043] (2) Preparation of porous resin material by high internal phase emulsion polymerization

[0044] 1) Preparation of O / W type high internal phase emulsion

[0045] Under mechanical stirring, take 4mL of the prepared phenolic resin prepolymer, 0.1g N,N-methylenebisacrylamide (MBA), 0.01g sodium persulfate (SPS, Na 2 S 2 o 8 ), added to a 100mL three-necked flask and mixed well, added 850.15g of surfactant Tween dropwise, and stirred at 900-1100rpm to obtain the water phase; then, continued to stir at 400-600rpm, and added 16mL of liquid Paraffin, stirring co...

Embodiment 3

[0053] (1) Preparation of phenolic resin prepolymer

[0054] Take about 2.4g of solid phenol into a round bottom flask and heat it up to 43°C to melt into a liquid state, add a certain amount of sodium hydroxide solution (0.02g / mL), start stirring for about 10min, drop by drop while stirring Add 5 mL of formaldehyde solution dropwise, stir well for 5 min, then raise the temperature to 73°C for one hour reaction.

[0055] (2) Preparation of porous resin material by high internal phase emulsion polymerization

[0056] 1) Preparation of O / W type high internal phase emulsion

[0057] Under mechanical stirring, take 8mL prepared phenolic resin prepolymer, 0.4g N,N-methylenebisacrylamide (MBA), 0.01g sodium persulfate (SPS, Na 2 S 2 o 8 ), added to a 100mL three-necked flask and mixed thoroughly, added dropwise 850.2g of surfactant Tween, stirred at 900-1100rpm to obtain the water phase; then, continued to stir at 400-600rpm, and added dropwise 32mL of liquid Paraffin, stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com