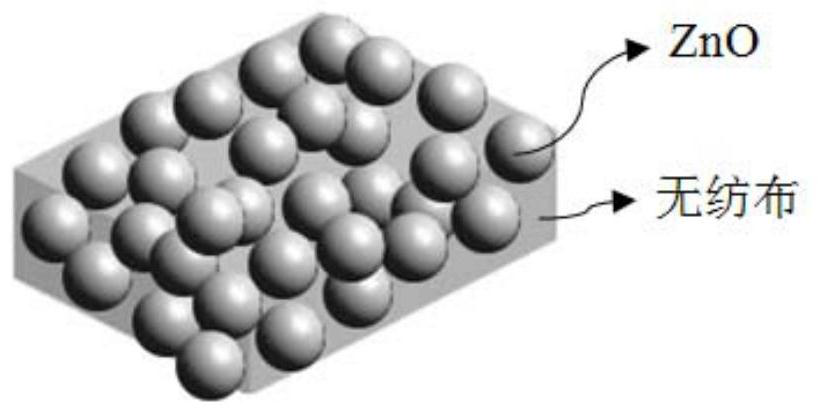

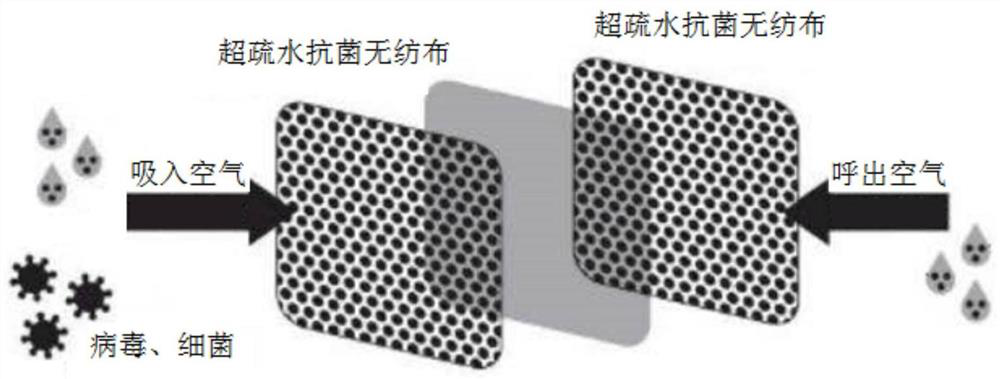

Super-hydrophobic antibacterial non-woven fabric, mask and preparation method and application of super-hydrophobic antibacterial non-woven fabric

A non-woven fabric and super-hydrophobic technology, applied in the field of materials, can solve the problems of inability to wash antibacterial properties and achieve excellent super-hydrophobic properties and good antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] S1. 25 grams of 3s non-woven fabric (the material is polypropylene, the same below) is ultrasonically cleaned with petroleum ether, absolute ethanol, and deionized water for 1 hour, and then dried in a 60°C drying oven to obtain a pretreated non-woven fabric. cloth.

[0035] S2. Take hexamethylenetetramine ethanol solution, drop zinc nitrate ethanol solution into it at a speed of about 2 drops / second, stir while adding, and continue stirring for 5 minutes after the dropwise addition to obtain hexamethylenetetramine Hexamethylenetetramine / zinc nitrate mixed ethanol solution with concentration of 0.05mol / L and zinc nitrate concentration of 0.05mol / L. Immerse the pretreated non-woven fabric in the above-mentioned hexamethylenetetramine / zinc nitrate mixed ethanol solution, place it in a drying oven at 95°C and heat it for 4 hours, take out the non-woven fabric from the solution after heating, and rinse it repeatedly with deionized water. Place it in a drying oven at 60°C a...

Embodiment 2

[0038] S1. 25 grams of 3s non-woven fabrics were ultrasonically cleaned with petroleum ether, absolute ethanol, and deionized water for 1 hour respectively, and then dried in a drying oven at 60° C. to obtain pretreated non-woven fabrics.

[0039] S2. Take hexamethylenetetramine ethanol solution, drop zinc nitrate ethanol solution into it at a speed of about 2 drops / second, stir while adding, and continue stirring for 5 minutes after the dropwise addition to obtain hexamethylenetetramine Hexamethylenetetramine / zinc nitrate mixed ethanol solution with concentration of 0.1mol / L and zinc nitrate concentration of 0.1mol / L. Immerse the pretreated non-woven fabric in the above-mentioned hexamethylenetetramine / zinc nitrate mixed ethanol solution, place it in a drying oven at 90°C and heat it for 6 hours, take out the non-woven fabric from the solution after heating, and rinse it repeatedly with deionized water. Dry in a drying oven at 60°C.

[0040] S3. Step S2 is repeated for 5 tim...

Embodiment 3

[0043] S1. 35 grams of 3s non-woven fabric were ultrasonically cleaned with petroleum ether, absolute ethanol, and deionized water for 1 hour, and then dried in a 60° C. drying oven to obtain a pretreated non-woven fabric.

[0044] S2. Take hexamethylenetetramine ethanol solution, drop zinc nitrate ethanol solution into it at a speed of about 2 drops / second, stir while adding, and continue stirring for 5 minutes after the dropwise addition to obtain hexamethylenetetramine Hexamethylenetetramine / zinc nitrate mixed ethanol solution with concentration of 0.08mol / L and zinc nitrate concentration of 0.08mol / L. Immerse the pretreated non-woven fabric in the above-mentioned hexamethylenetetramine / zinc nitrate mixed ethanol solution, place it in a drying oven at 100°C and heat it for 2 hours, take out the non-woven fabric from the solution after heating, and rinse it repeatedly with deionized water. Place it in a drying oven at 60°C and dry it to obtain a superhydrophobic antibacteria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com