Modified waterborne polyurethane latex film and preparation method thereof

A water-based polyurethane and latex film technology, applied in chemical instruments and methods, coatings, layered products, etc., can solve problems such as only cashmere knitted fabrics, unable to obtain water-repellent products, and limited product water repellency, etc. Improve hydrophobic performance, strengthen negative ion release performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The concrete steps of preparation are:

[0037] Step 1, first casting the water-based polyurethane emulsion on the substrate, and drying it at 40°C to form a film; wherein, the substrate is flat glass to obtain a water-based polyurethane emulsion film. Then dissolve polyvinylidene fluoride into the solvent to prepare a polyvinylidene fluoride solution with a solid content of 8% as a spraying liquid; wherein, the solvent is N,N-dimethylformamide (or tetrahydrofuran, or two mixture of species).

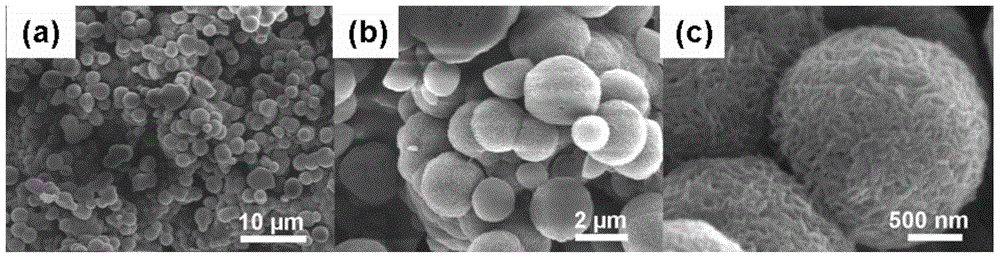

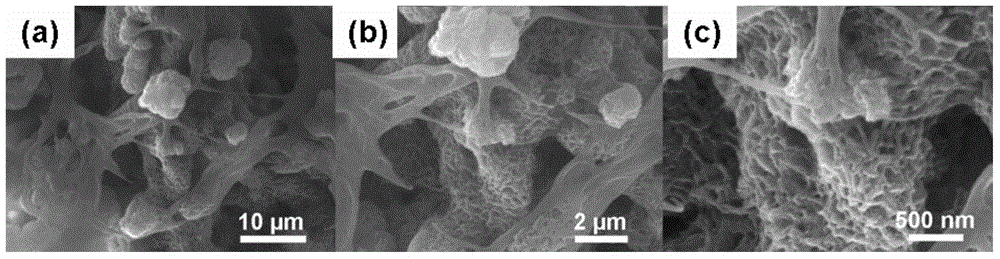

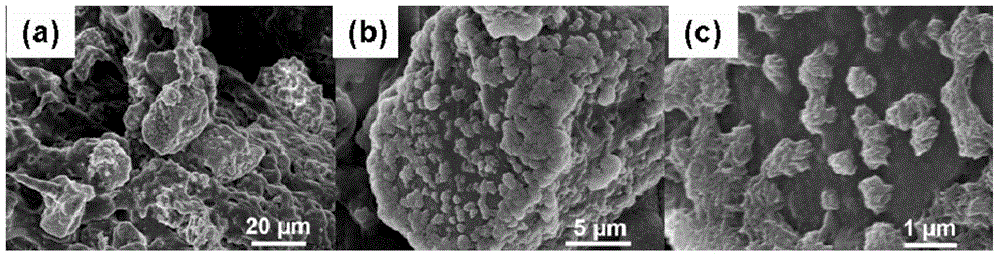

[0038] Step 2, first spray the spray liquid onto the water-based polyurethane latex film, and dry it at room temperature for 5 hours; wherein, the pressure during spraying is 2×10 5 Pa, an intermediate product was obtained. Then the intermediate product was dried at 60°C to form a film, and a product similar to figure 1 and Figure 5 shown, and as Figure 6 The modified waterborne polyurethane latex films are shown in the data.

Embodiment 2

[0040] The concrete steps of preparation are:

[0041] Step 1, first cast the water-based polyurethane emulsion on the substrate, and dry it at 50°C to form a film; wherein, the substrate is flat glass to obtain a water-based polyurethane emulsion film. Then dissolve the polytetrafluoroethylene into the solvent to prepare a polyvinylidene fluoride solution with a solid content of 9% as a spraying liquid; wherein, the solvent is N,N-dimethylformamide (or tetrahydrofuran, or two mixture of species).

[0042] Step 2, first spray the spray liquid onto the water-based polyurethane latex film, and dry it at room temperature for 5.5 hours; wherein, the pressure during spraying is 2.3×10 5 Pa, an intermediate product was obtained. Then the intermediate product was dried at 65°C to form a film, and a product similar to figure 1 and Figure 5 shown, and as Figure 6 The modified waterborne polyurethane latex films are shown in the data.

Embodiment 3

[0044] The concrete steps of preparation are:

[0045] Step 1, first cast the water-based polyurethane emulsion on the substrate, and dry it at 60°C to form a film; wherein, the substrate is flat glass to obtain a water-based polyurethane emulsion film. Then dissolve polyvinylidene fluoride into the solvent to prepare a polyvinylidene fluoride solution with a solid content of 10% as a spraying liquid; wherein, the solvent is N,N-dimethylformamide (or tetrahydrofuran, or two mixture of species).

[0046] Step 2, first spray the spray liquid onto the water-based polyurethane latex film, and dry it at room temperature for 6 hours; wherein, the pressure during spraying is 2.5×10 5 Pa, an intermediate product was obtained. Then the intermediate product was dried at 70°C to form a film, and the following figure 1 and Figure 5 shown, and as Figure 6 The modified waterborne polyurethane latex films are shown in the data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com